Modified alkyd finish paint capable of being thickly coated and preparation method thereof

A modified and alkyd technology, used in coatings, polyester coatings, etc., can solve the problem of thick coating, improve flexibility, save time and labor costs, and improve coating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

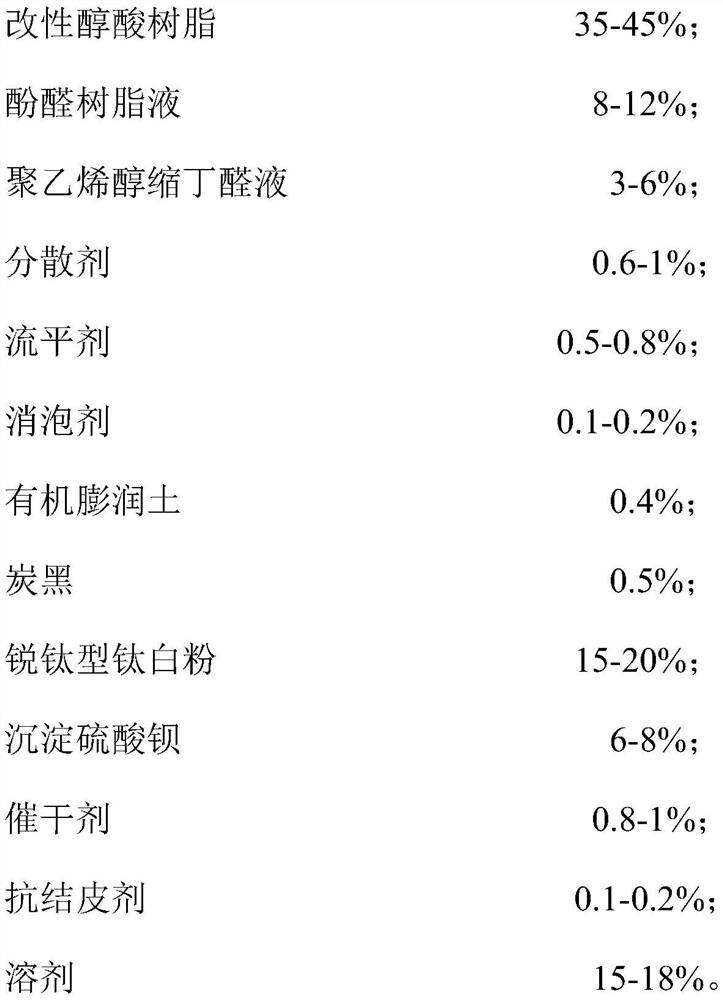

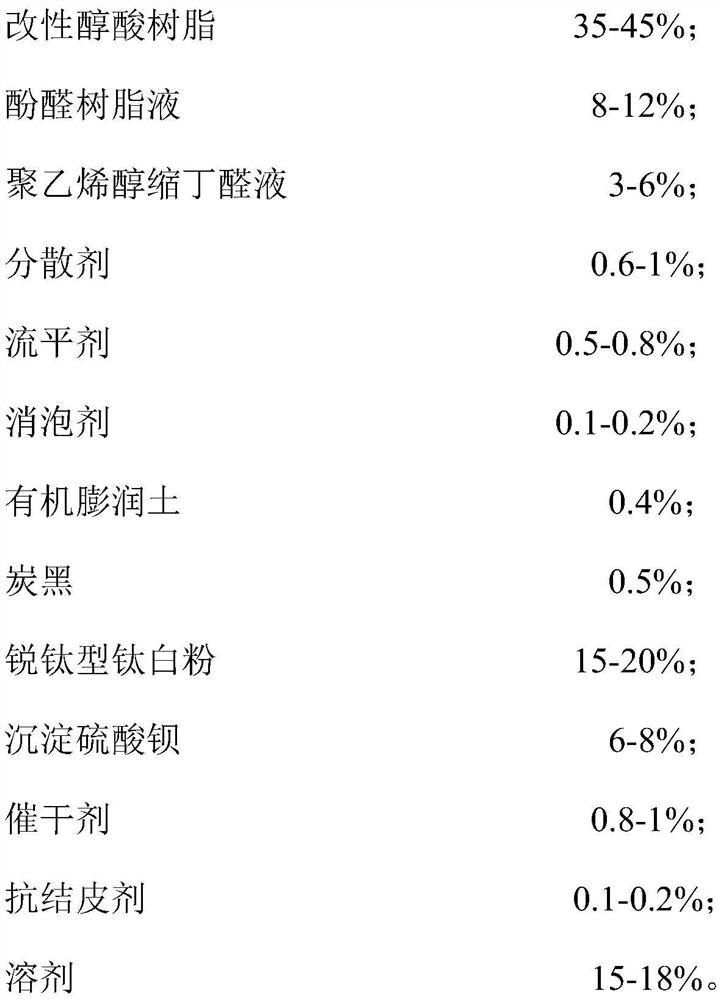

[0036] The preparation method of the thick coating modified alkyd topcoat provided by the invention may further comprise the steps:

[0037] 1) Prepare modified alkyd resin:

[0038] Add 16-20% soyoleic acid, 8-12% benzoic acid, 12-15% pentaerythritol, 16-19% phthalic anhydride and 3% reflux xylene into the reaction kettle, start stirring and cooling water, and heat up to 200-210°C , heat preservation and reflux dehydration for 2 hours, continue to heat up to 220-230 ° C, heat preservation and reflux until the acid value and viscosity are qualified, then cool down, add 37-40% xylene and dilute to obtain the modified alkyd resin.

[0039] 2) Preparation of phenolic resin liquid:

[0040] Measure 15-20% xylene, 15-20% toluene, 5-10% propylene glycol methyl ether acetate and 50-60% phenolic resin into the kettle, start stirring, heat up to 70-80°C for 3 hours, until fully dissolved, Take a sample to check that there is no particulate matter, and filter the discharge to obtain t...

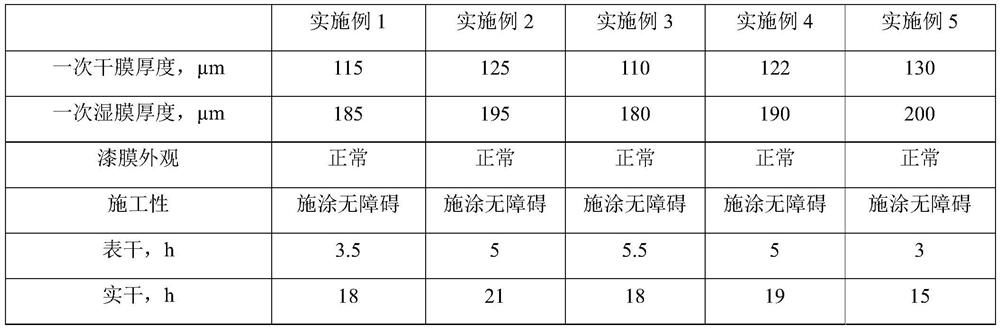

Embodiment 1

[0049] 1) Prepare modified alkyd resin:

[0050] Add 16% soyoleic acid, 12% benzoic acid, 15% pentaerythritol, 17% phthalic anhydride and 3% reflux xylene into the reaction kettle, start stirring and cooling water, heat up to 200°C, heat preservation and reflux dehydration for 2 hours, and continue to heat up to 230°C , heat preservation and reflux until the acid value and viscosity are qualified, then lower the temperature, add 37% xylene and dilute to obtain the modified alkyd resin.

[0051] 2) Preparation of phenolic resin liquid:

[0052] Measure 18% xylene, 17% toluene, 5% propylene glycol methyl ether acetate and 60% phenolic resin into the kettle, start stirring, raise the temperature to 70°C and keep it for 3 hours, until it is fully dissolved, take a sample to check that there are no particles, and filter out the product. The phenolic resin liquid.

[0053] 3) Preparation of polyvinyl butyral liquid:

[0054] Measure 32% ethanol, 58% propylene glycol methyl ether ac...

Embodiment 2

[0059] 1) Prepare modified alkyd resin:

[0060] Add 18% soyoleic acid, 8% benzoic acid, 15% pentaerythritol, 16% phthalic anhydride and 3% reflux xylene into the reaction kettle, start stirring and cooling water, heat up to 210°C, heat preservation and reflux dehydration for 2 hours, and continue to heat up to 220°C , heat preservation and reflux until the acid value and viscosity are qualified, then lower the temperature, add 40% xylene and dilute to obtain the modified alkyd resin.

[0061] 2) Preparation of phenolic resin liquid:

[0062] Measure 15% xylene, 20% toluene, 5% propylene glycol methyl ether acetate and 60% phenolic resin into the kettle, start stirring, raise the temperature to 80°C and keep it for 3 hours until it is fully dissolved, take a sample to check that there are no particles, and filter out the product. The phenolic resin liquid.

[0063] 3) Preparation of polyvinyl butyral liquid:

[0064] Measure 25% ethanol, 65% propylene glycol methyl ether ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com