Color master batch with natural antibacterial function and preparation process thereof

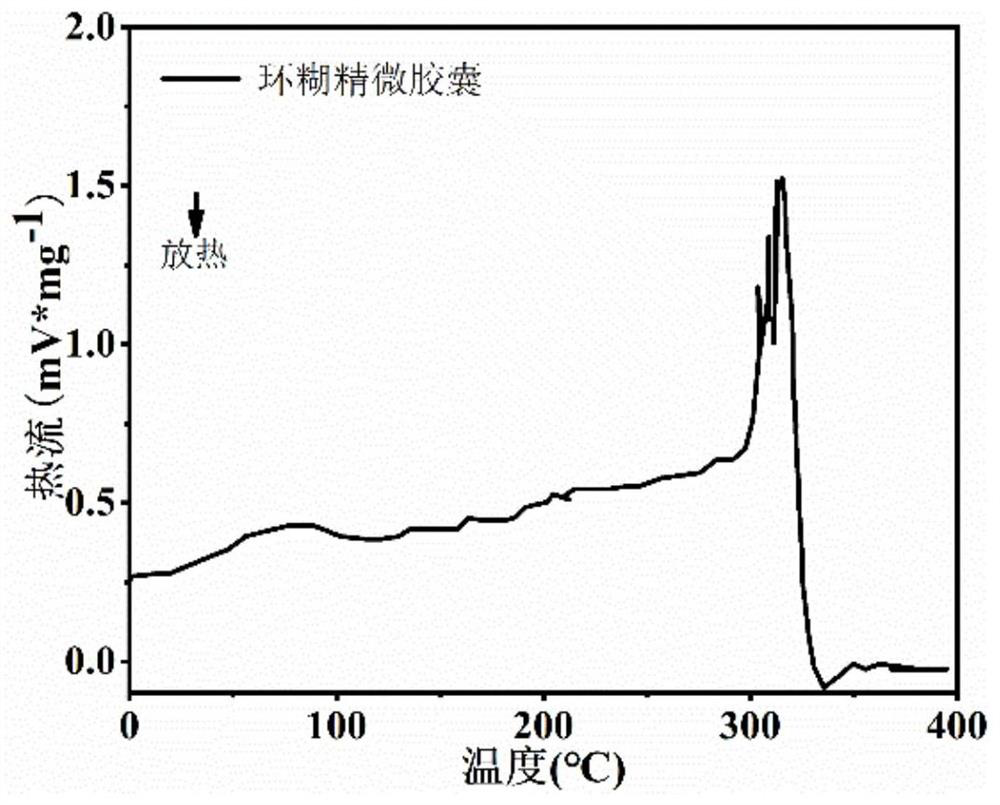

A natural antibacterial, color masterbatch technology, applied in the field of new materials, can solve the problems of pollution in the production process, high price, unable to withstand the high temperature of color masterbatch, etc., and achieve the effect of breaking through the high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Select the resin carrier: the intrinsic viscosity is 1.306dL / g, the melting point is 167°C, and the particle size is 60 mesh PLA powder.

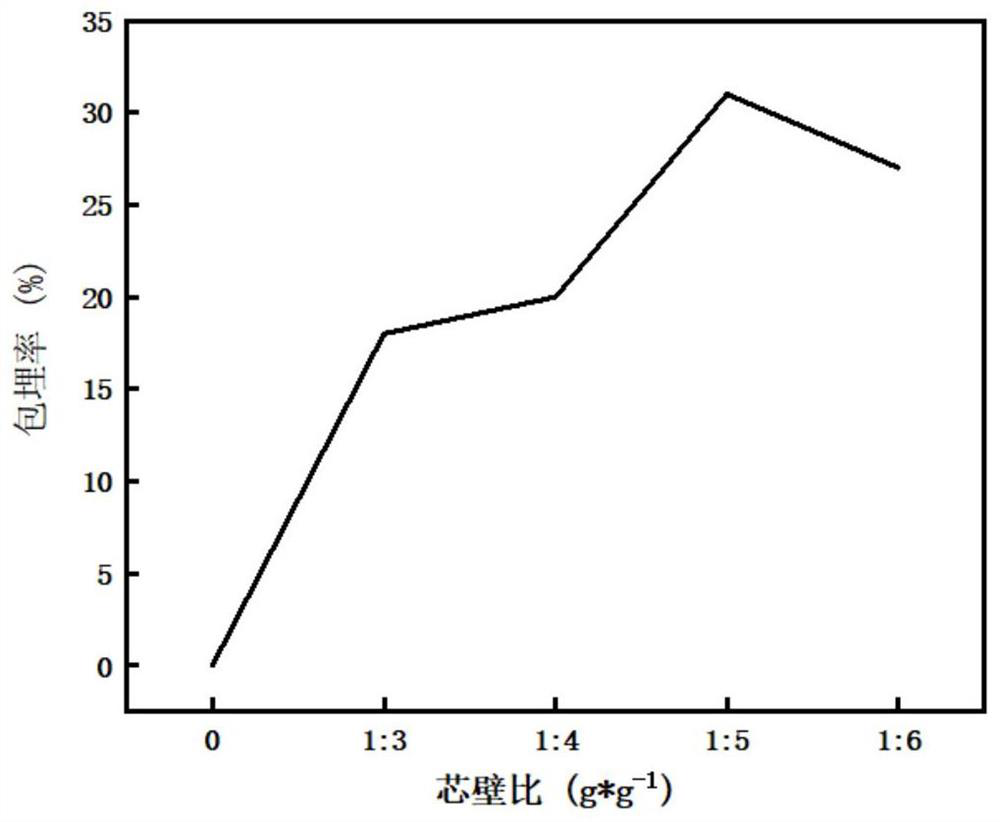

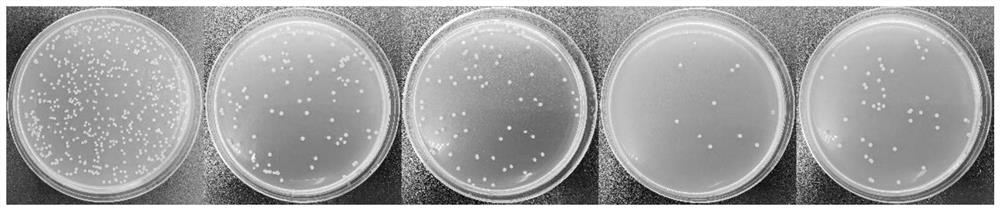

[0045]Preparation of natural antibacterial functional masterbatch: Add 67wt% PLA powder, 18wt% pigment, 10wt% mint antibacterial agent with a core-wall ratio of 1:5, 2wt% dispersant, and 3wt% lubricant to the temperature Stir in a high-speed mixer with a temperature of 20°C and a speed of 1500r / min for 90s to make the materials evenly mixed. The mixed materials are fed into the twin-screw extruder by quantitative weighing. 170°C, 175°C, 180°C, 190°C, 185°C, 180°C, 180°C, the material is melted, sheared and mixed, extruded through the die head of the extruder, the melt is cooled into a solid state through the water tank, and passed through the blower After drying, enter the granulator to cut into particles of the required size, and finally sieve in a 60-mesh vibrating screen and enter the silo to obtain natural antibacterial color mas...

Embodiment 2

[0047] Select resin carrier: PLA powder with intrinsic viscosity 1.306dL / g, melting point 167°C, particle size 60 mesh.

[0048] Preparation of natural antibacterial functional masterbatch: 67wt% PLA powder, 18wt% pigment and 10wt% honeysuckle antibacterial agent with a core-wall ratio of 1:5, 2wt% dispersant, and 3wt% lubricant were added to the temperature Stir in a high-speed mixer with a temperature of 20°C and a speed of 1600r / min for 90s to make the materials evenly mixed. The mixed materials are fed into the twin-screw extruder through quantitative weighing. 170°C, 175°C, 180°C, 190°C, 185°C, 180°C, 180°C, the material is melted, sheared and mixed, extruded through the die head of the extruder, the melt is cooled into a solid state through the water tank, and passed through the blower After drying, enter the granulator to cut into particles of the required size, and finally sieve in a 60-mesh vibrating screen and enter the silo to obtain natural antibacterial color mast...

Embodiment 3

[0050] Select resin carrier: water content 0.4%, ash content 0.07%, melt index 30g / 10min, melting point 261°C, particle size 100 mesh PET powder.

[0051] Preparation of natural antibacterial functional masterbatch: add 60wt% of PET powder, 15wt% of pigment and 20wt% of wormwood antibacterial agent with a core-wall ratio of 1:5, 2wt% of dispersant, and 3wt% of lubricant Stir in a high-speed mixer with a temperature of 20°C and a speed of 1600r / min for 60 seconds to mix the materials evenly. The mixture is quantitatively weighed and fed into the twin-screw extruder. The twin-screw temperature zones are set at 250°C, 255°C, and 260°C. . After being blown dry by a blower, it enters a granulator to cut into particles of the required size, and finally sieves in a 100-mesh vibrating sieve and enters the silo to obtain natural antibacterial color masterbatch finished products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com