Nut cracker

A nut shelling machine and the technology of the shelling machine, which are applied in the fields of shelling, pod removal, food science, etc., can solve the problems of nuts with sharp corners that are easy to be split in half, unable to achieve shell breaking, and unsatisfactory shell breaking effect, etc. Achieve good percussion speed and strength, simplify processing, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

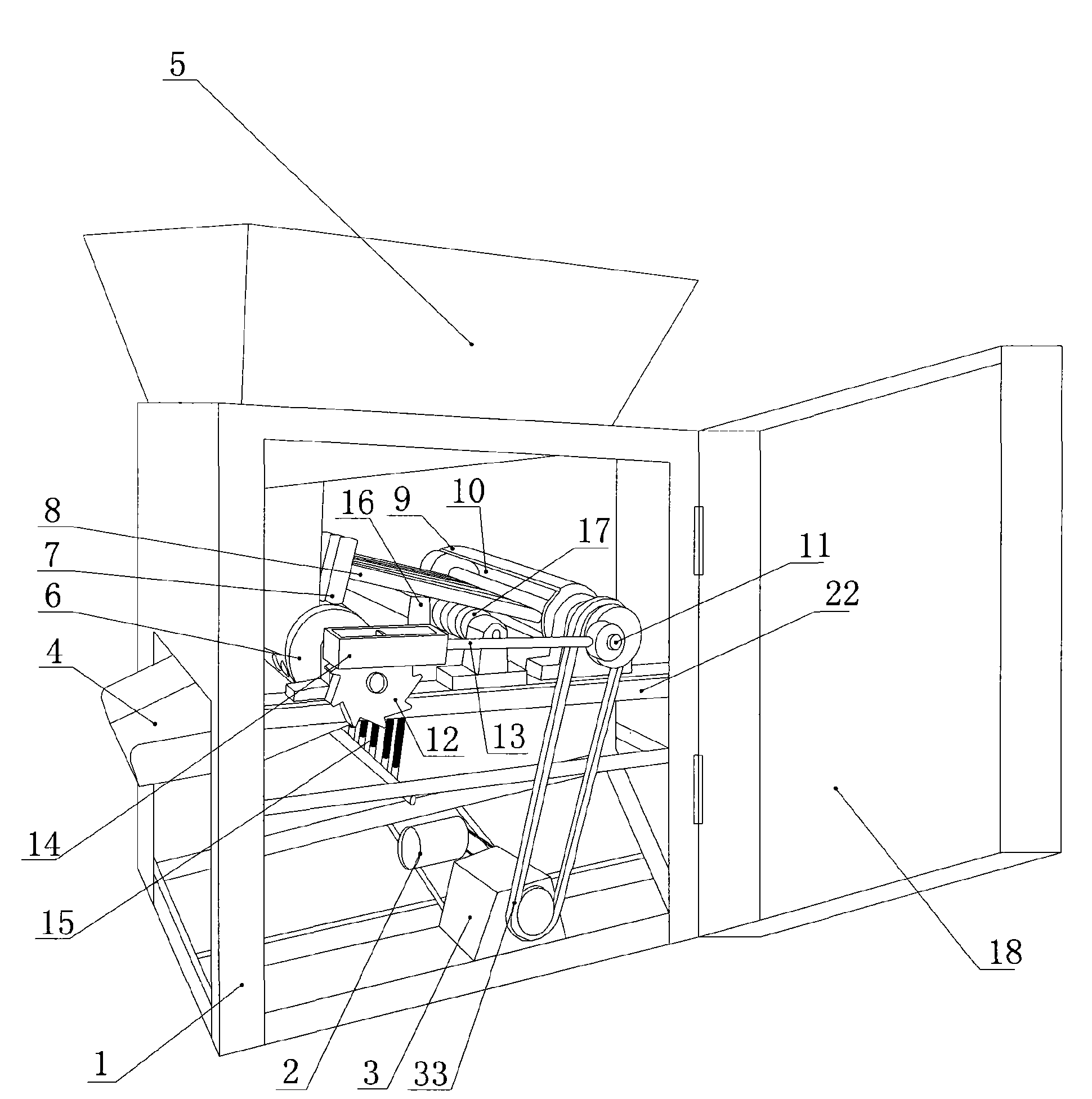

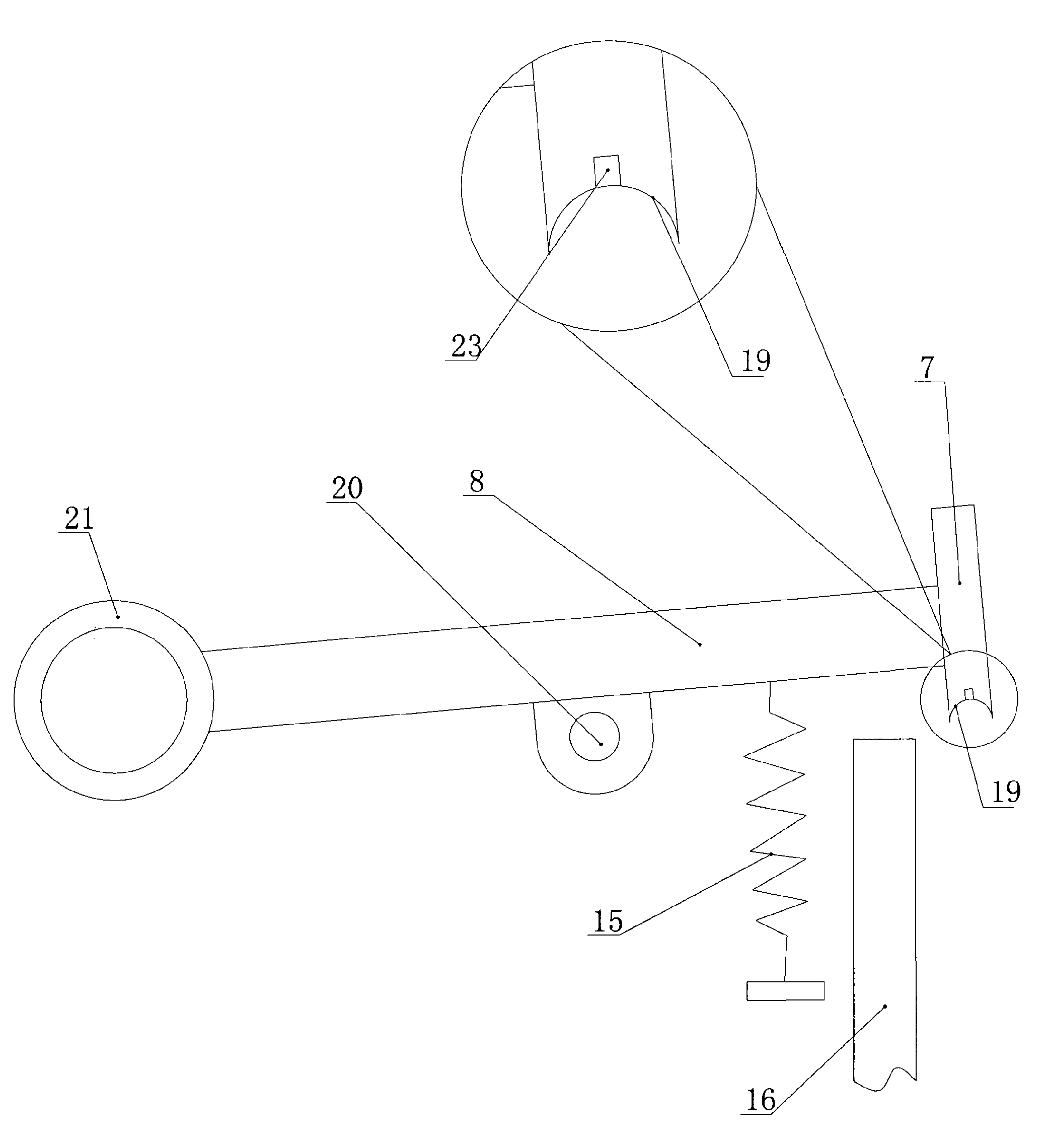

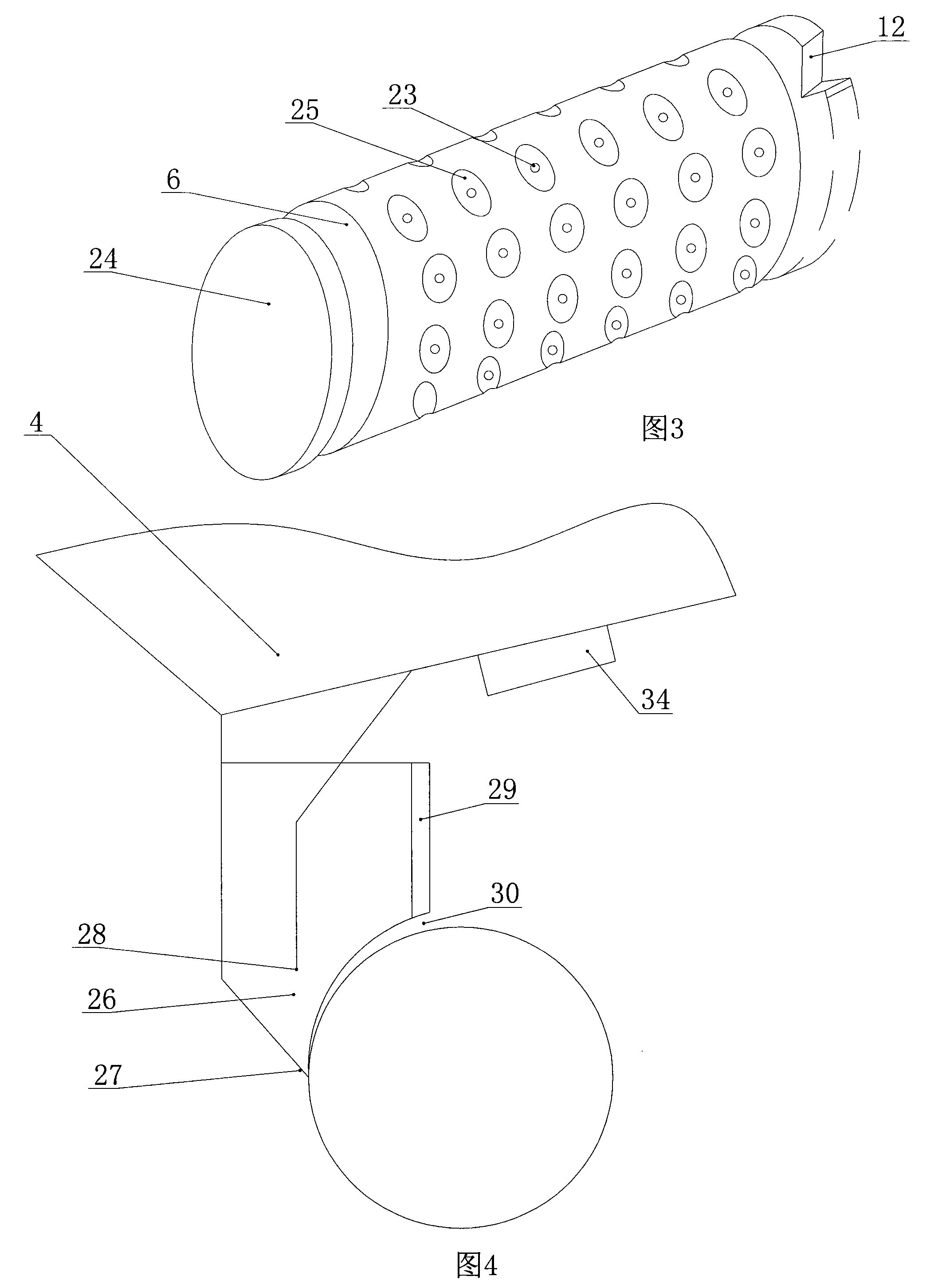

[0025] Embodiment: a kind of cracking machine for nuts (see attached figure 1 ), the square frame 1 is a frame structure, the middle is provided with a crossbeam 22, the side is provided with an opening door 18 through a hinge, the top of the frame is provided with a stainless steel feed hopper 5, and the side is provided with a stainless steel discharge hopper 4, and on the crossbeam The roller 6 made of high-strength nylon, the rotating shaft 17 and the driving shaft 9 are fixed through the bearing seat, the driving arm 8 is fixed on the rotating shaft through the support, and several rows of evenly distributed concave circular holes are arranged on the circumferential surface of the roller. 25 (see attached image 3 ), the diameter of the well is 30mm, and the depth is 5mm. The central part of the well is provided with a cylindrical sharp corner cavity 23, and the front end of the driving arm is provided with a hammer 7 (see attached figure 2), the lower end face of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com