Preparation method of super-smooth graphene molar structure coating

A graphene and coating technology, applied in the field of material technology and tribology, can solve the problem of unstable non-commensurate contact state, and achieve the effect of avoiding friction anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A kind of preparation method of ultra-smooth graphene molar structure coating:

[0019] Mix the graphene powder and the grinding beads in the planetary ball mill according to the weight ratio (g / g) of 1:50~120, the volume of the graphene powder is less than 10% of the volume of the ball mill tank, and the speed is controlled at 50~600rpm Ball milling is carried out under the condition that the ball milling time is 5~100h, and the graphene molar structure film is prepared on the milling beads in the random rolling between the milling beads and the graphene powder by virtue of the ability of the graphene sheets to align.

[0020] Graphene powder has a clear flake shape and a smooth surface. The diameter of the sheet is between 20 and 500nm, the number of graphene layers in the sheet is less than 15, and the surface of the sheet has no obvious wrinkles and is smooth.

[0021] Grinding beads refer to one of steel balls, alumina balls, zirconia balls, silicon nitride balls ...

Embodiment 1

[0025] Embodiment 1 A kind of preparation method of ultra-smooth graphene molar structure coating:

[0026] Mix the graphene powder with a sheet diameter of about 200nm, the number of layers less than 10, smooth surface, and clear flakes with 5mm alumina grinding beads in a planetary ball mill at a weight ratio (g / g) of 1:100, and the graphene powder The volume of the body accounts for 8% of the volume of the ball mill tank, and the ball mill is carried out under the condition that the rotating speed is controlled at 200rpm and the ball milling time is 20h. Graphene molar structure films were prepared on grinding beads.

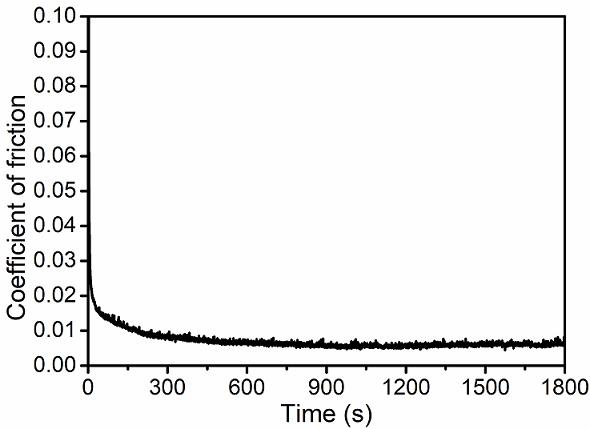

[0027] The graphene molar structure film is in parallel contact with the sheets, and the rotation angle between the sheets is 30 o , showing a non-commensurate contact state to produce moiré fringes; then the graphene moiré structure film and the hydrogen-containing carbon film form a friction pair, under 7N load, 10cm / s speed range, 1.1mm 2 Sp in the graph...

Embodiment 2

[0029] Embodiment 2 A kind of preparation method of ultra-smooth graphene molar structure coating:

[0030] Mix graphene powder with a diameter of about 20nm, layers less than 15, smooth surface, and clear flakes with 10mm alumina grinding beads in a planetary ball mill at a weight ratio (g / g) of 1:50, graphene powder The volume of the body accounts for 6% of the volume of the ball milling tank, and the ball milling is carried out under the condition that the rotating speed is controlled at 100rpm and the ball milling time is 50h. With the help of the ability of the graphene sheets to be oriented, in the random rolling between the grinding beads and the graphene powder, Graphene molar structure films were prepared on grinding beads.

[0031] The graphene molar structure film is in parallel contact with the sheets, and the rotation angle between the sheets is 20 o , showing a non-commensurate contact state to produce moiré fringes; then the graphene moiré structure film and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com