Preparation method of macroscopically ultra-smooth silver nitrate composite carbon-based film

A silver nitrate and composite carbon technology, which is applied to the surface coating liquid device, ion implantation plating, gaseous chemical plating, etc., can solve the problems of large environmental dependence and difficult engineering application, and achieve high efficiency and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

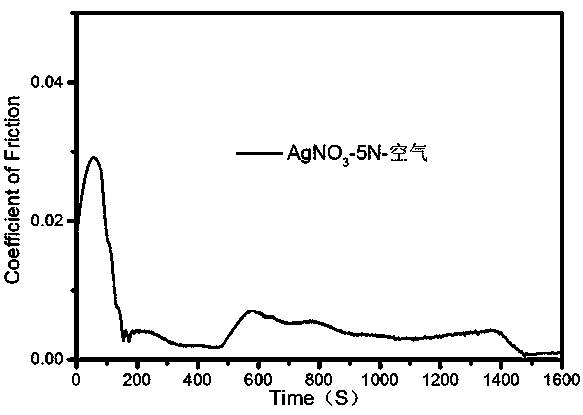

Image

Examples

Embodiment 1

[0017] Example 1 A method for preparing a macroscopic ultra-smooth silver nitrate composite carbon-based film: first prepare a diamond-like carbon film with a thickness of 1 micron and a hydrogen content of 0%; then use alcohol to ultrasonically clean the diamond-like carbon film 8min; Finally, drop or smear or spray or dip the silver nitrate solution with a mass concentration of 1% evenly on the diamond-like carbon film to make it as thick as 100nm, and dry it naturally at 25°C for 72 hours to obtain a load with a thickness of 100nm. Carbon-based films of silver nitrate.

[0018] Among them: the diamond-like carbon film with hydrogen content of 0% is prepared by arc ion plating method. The specific process is as follows:

[0019] A Ti target was selected, argon gas was introduced, the gas pressure was 1Pa, the arc current was 120A, the bias voltage was 300V, and the deposition was performed for 15 minutes.

[0020] Close the titanium target, open the graphite arc target, ke...

Embodiment 2

[0021] Example 2 A method for preparing a macroscopic ultra-smooth silver nitrate composite carbon-based film: first prepare a diamond-like carbon film with a thickness of 1 micron and a hydrogen content of 30%; then use alcohol to ultrasonically clean the diamond-like carbon film 15min; Finally, drop or smear or spray or dip the silver nitrate solution with a mass concentration of 0.5% evenly on the diamond-like carbon film to make the thickness to 50nm, and dry it naturally at 25°C for 72h to obtain a load with a thickness of 50nm. Carbon-based films of silver nitrate.

[0022] Among them: the diamond-like carbon film with a hydrogen content of 30% is prepared by plasma chemical vapor deposition. The specific process is as follows:

[0023] Evacuate to a vacuum below 0.001 Pa, and start coating.

[0024] Infuse argon gas to 20 Pa, bias at 1200V, and bombard for 30 minutes to remove pollutants on the surface of the substrate.

[0025] Adjust the argon gas to 10 Pa, bias 80...

Embodiment 3

[0028] Example 3 A method for preparing a macroscopic ultra-smooth silver nitrate composite carbon-based film: first prepare a diamond-like carbon film with a thickness of 1 micron and a hydrogen content of 20%; then use alcohol to ultrasonically clean the diamond-like carbon film 10min; Finally, drop or smear or spray or dip the silver nitrate solution with a mass concentration of 0.7% evenly on the diamond-like carbon film to make the thickness to 70nm, and dry it naturally at 25°C for 72h to obtain a load with a thickness of 70nm. Carbon-based films of silver nitrate.

[0029] Among them: the diamond-like carbon film with a hydrogen content of 20% is prepared by plasma chemical vapor deposition. The specific process is as follows:

[0030] Made by plasma chemical vapor deposition method. The specific process is as follows:

[0031] Evacuate to a vacuum below 0.001 Pa, and start coating.

[0032] Infuse argon gas to 20 Pa, bias at 1200V, and bombard for 30 minutes to rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com