A kind of composite lubricating composition and lubricating material

A technology for lubricating compositions and lubricating materials, applied in the direction of lubricating compositions, additives, petroleum industry, etc., can solve the problems of surfactant layer damage, limited bearing capacity, narrow range, etc., and achieve reduced viscosity and shear resistance, bearing The effect of good ability and good lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] With the β-diketone (wherein, R as described in formula (1) molecular structural formula 1 =-C 2 h 5 , R 2 =-C 6 h 13 ) was dropped on the steel plate and heated to 180°C for about 5 minutes to simulate the implementation of tribochemical reactions. After the reaction, the remaining β-diketone was washed away with acetone to obtain a chemical adsorption layer.

[0026] Among them, R 1 =-C 2 h 5 , R 2 =-C 6 h 13 .

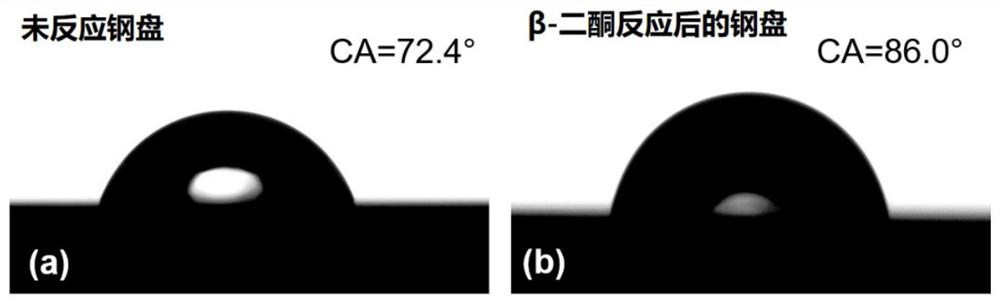

[0027] The contact angle test of water droplets is carried out on the surface of the steel plate with chemical adsorption layer and the unreacted steel surface, such as figure 1 As shown, it was found that the contact angle of the steel disc with the chemical adsorption layer increased significantly. After calculation, the chemical adsorption of the β-diketone of the present embodiment can change the contact angle of the steel plate from 41mJ / m 2 Reduced to 37mJ / m 2 . Combined with the FCK rule according to the orientation of liquid crystals...

Embodiment 2

[0033]The difference between this example and Example 1 is that in the chemical structural formula of β-diketone in this example, R1 and R2 are the same, both being -C 3 h 6 COOCH 3 , the content of β-diketone in the compound oil of 5CB and β-diketone is 15wt%. Other steps, reagents and parameters are the same as in Example 1.

[0034] By testing the contact angle of water droplets before and after the β-diketone modification of the steel surface in this embodiment, the contact angle increases from 72.4° to 83.1° before the β-diketone modification. Using the β-diketone of this embodiment The chemical adsorption layer formed on the surface of the ketone-treated steel disk made the contact angle of the steel disk significantly increased.

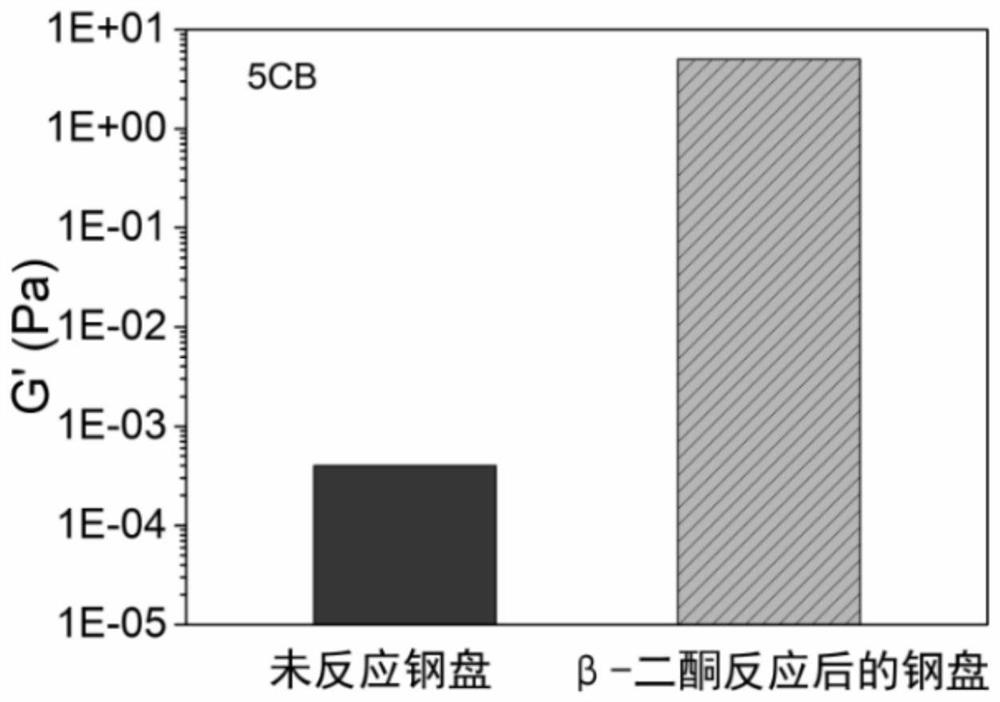

[0035] Using 5CB on the surface of the β-diketone modified steel in this embodiment, the storage modulus G' of the steel disk surface is tested by viscoelasticity through a rotational rheometer, and the conditions are: reciprocating frequen...

Embodiment 3

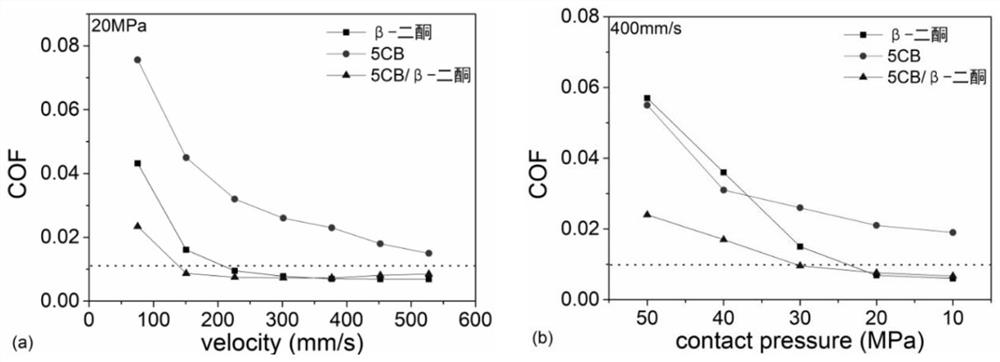

[0038] The difference between this embodiment and embodiment 1 lies in that the liquid crystal base oil used is MBBA. Other steps, reagents and parameters are the same as in Example 1. The reduction of the surface energy of steel by the β-diketone prepared in this example was confirmed by the contact angle test, and the contact angle increased from 72.4° before modification to 86.0°. The viscoelasticity of MBBA on the surface of modified steel was confirmed by rotational rheometer, and its storage modulus was almost zero compared with that of unreacted steel plate (10 -4 order of magnitude) increased to 11Pa. The super-slip performance of 5CB / β-diketone has been confirmed by the multifunctional friction testing machine. Under the constant contact pressure of 20MPa, the minimum super-slip speed is extended from 220mm / s of pure β-diketone to 121mm / s; at a constant speed of 400mm / s , the maximum contact pressure of ultra-smooth is expanded from 22MPa to 27MPa. After the rubbin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com