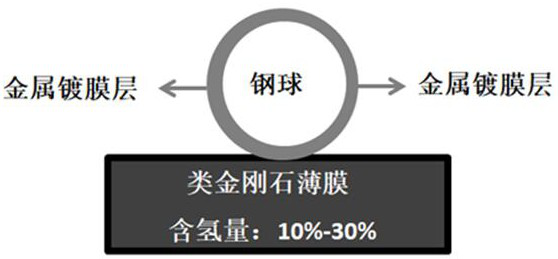

Method for realizing macroscopic super-lubricity through nano metal coated steel ball and hydrogen-containing carbon film pair

A technology of nano-metal and carbon thin films, applied in the field of macroscopic super-slip, can solve problems such as difficult engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) GCr15 bearing steel (diameter 6mm) was ultrasonicated with tetrachloromethane and absolute ethanol for 30 minutes to remove the dirt and impurities on the surface of the steel ball. After cleaning, check that the steel ball has been cleaned and is ready to be used for coating;

[0015] (2) Coating the steel ball by the electroplating method of displacement reaction: take 0.6g of ammonium chloride, 0.6g of sodium sulfite, then add 30ml of water and 10ml of chloroauric acid solution with a concentration of 4g / L to obtain the required plating solution; Adjust the pH value of the reaction to 13, add the prepared steel balls to be plated, use a glass container for chemical plating, maintain the temperature at 60°C, and control the reaction time to 40min, to obtain steel balls with a gold-plated film thickness of 600nm;

[0016] (3) A diamond-like carbon film with a hydrogen content of 24% was prepared by plasma vapor deposition, and the film thickness was 1000 nm;

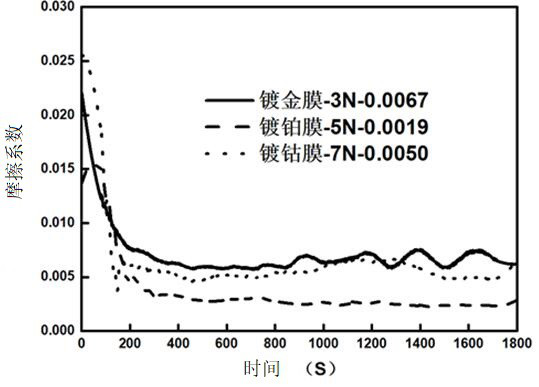

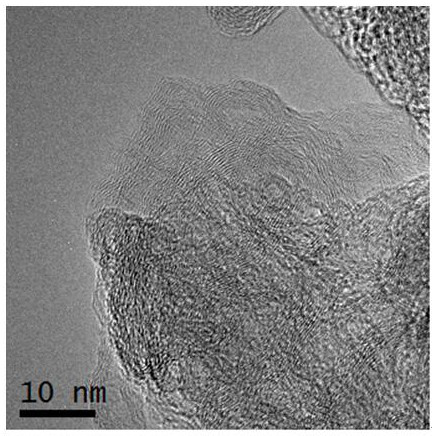

[001...

Embodiment 2

[0019] (1) 440c stainless steel balls (diameter 5mm) were ultrasonicated with tetrachloromethane and absolute ethanol for 30 minutes respectively to remove the dirt and impurities on the surface of the steel balls. After cleaning, check that the steel balls have been cleaned and are ready to be used for coating;

[0020] (2) Coating steel balls by electroplating by displacement reaction: Weigh 0.6g EDTA, 0.6g ammonium chloride, add 30ml water and 10ml potassium chloroplatinate solution with a concentration of 4g / L to obtain the required plating Adjust the pH value of the reaction to 13, then add the prepared steel balls to be plated, use a glass container for chemical plating, maintain the temperature at 60°C, and control the reaction time to 40min to obtain steel balls with a platinum-plated film thickness of 800nm;

[0021] (3) A diamond-like carbon film with a hydrogen content of 30% was prepared by plasma vapor deposition, and the film thickness was 800 nm;

[0022] (4) Te...

Embodiment 3

[0024] (1) 440c stainless steel balls (diameter 10mm) were ultrasonicated with tetrachloromethane and absolute ethanol for 30 minutes respectively to remove the dirt and impurities on the surface of the steel balls. After cleaning, check that the steel balls have been cleaned and are ready to be used for coating;

[0025] (2) Coating steel balls by electroplating by displacement reaction: Weigh 0.8g of cobalt chloride, 2g of potassium and sodium tartrate, and then add 30ml of water to obtain the required plating solution; adjust the pH of the reaction to 13, and then add For the prepared steel balls to be plated, use a glass container for chemical plating, maintain the temperature at 60°C, and control the reaction time to 40min, to obtain steel balls with a cobalt-plated film thickness of 800nm;

[0026] (3) The diamond-like carbon film with a hydrogen content of 27% was prepared by plasma vapor deposition method: the film thickness was 800 nm;

[0027] (4) Test the tribologic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com