Hard carbon composite material and preparation method and application thereof

A composite material and hard carbon technology, which is used in the preparation/purification of carbon, active material electrodes, electrical components, etc., can solve the problems of large irreversible capacity and low first efficiency of hard carbon materials, and achieve excellent first Coulomb efficiency and simple method. , mild and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] According to one aspect of the present invention, the present invention relates to a kind of preparation method of hard carbon composite material, comprises the following steps:

[0045] heat-treating the mixture of hard carbon material and pitch under inert gas conditions;

[0046] The preparation method of the hard carbon material comprises: performing phosphoric acid treatment, curing treatment, carbonization treatment and crushing treatment on the phenolic resin in sequence.

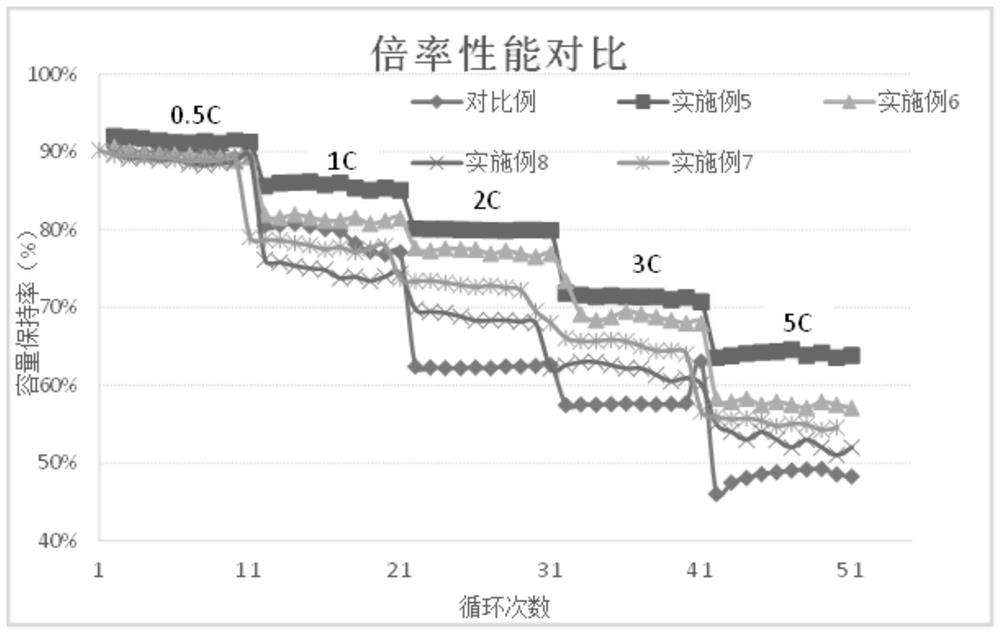

[0047] The method of the invention is simple, and the conditions are mild and controllable, and the obtained hard carbon composite material can improve the first efficiency when used for preparing batteries, and the batteries have better rate performance and capacity retention performance.

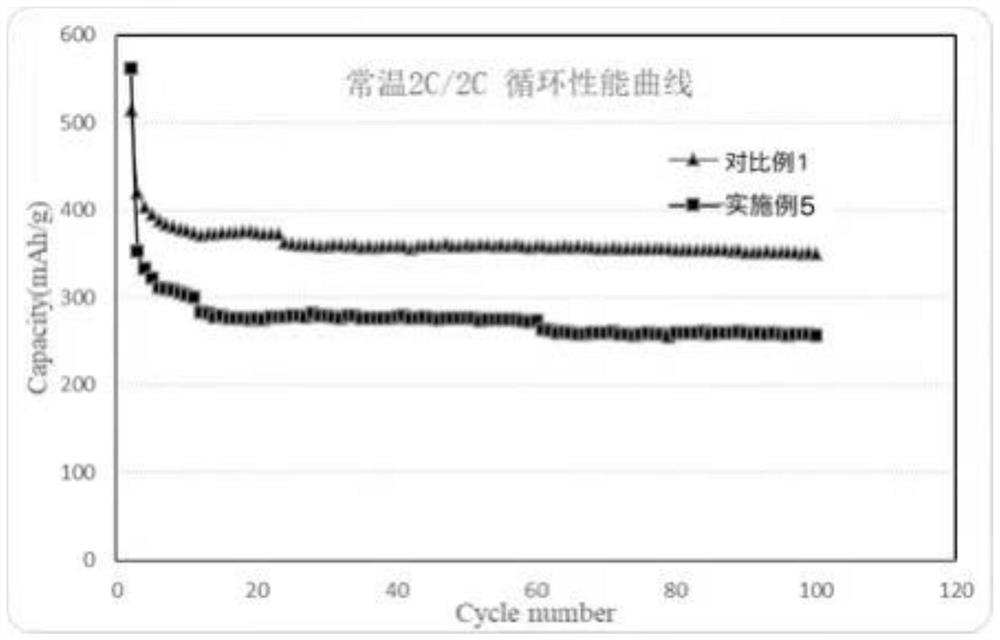

[0048] The invention utilizes the cross-linking reaction of phosphoric acid and phenolic resin to perform high-temperature pyrolysis after curing to mainly form P-O and P-C bonds. P-O and P-C bonds can im...

Embodiment 1

[0101] A preparation method of hard carbon composite material, comprising the following steps:

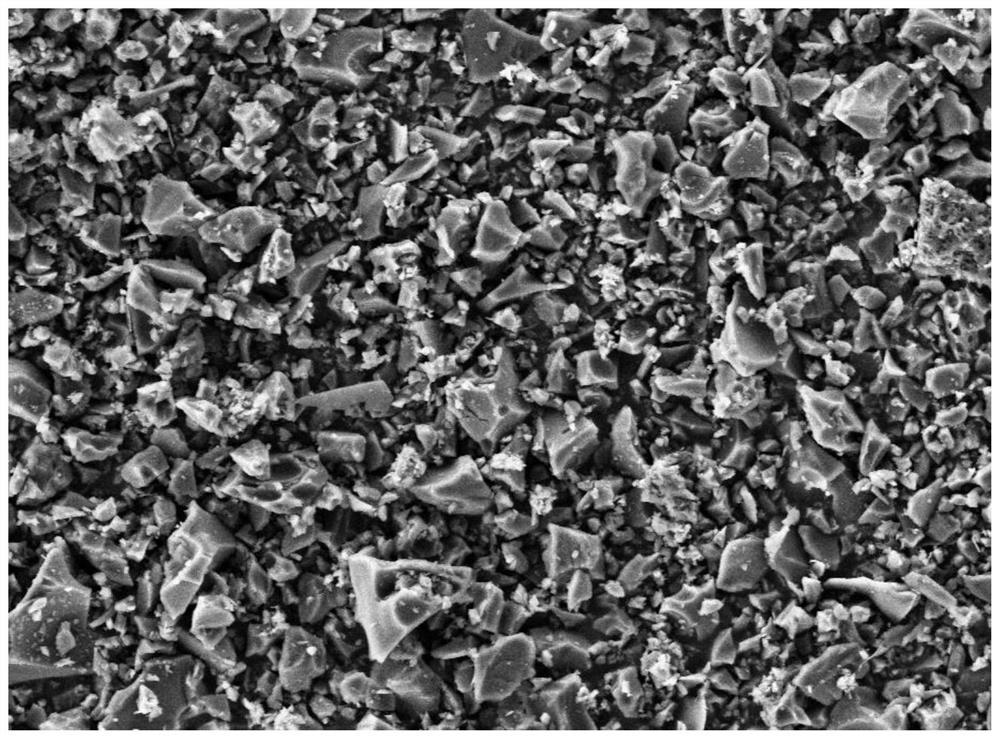

[0102] Weigh 300g of phenolic resin and dissolve it in 600mL of absolute ethanol, add 10g of hexamethylenetetramine and 30g of phosphoric acid under stirring conditions, stir for 5h to completely dissolve the phenolic resin, then filter with suction, and take the filtrate at 80°C Dry in an oven; put the dried sample into a tube furnace, and carry out carbonization at 800°C for 3 hours in an argon atmosphere at a heating rate of 5°C / min. The carbonized sample is ball milled in a ball mill at 400r / min 5h, then pass through a 400-mesh sieve; then mix the sieved material with 30g of medium-temperature coal tar pitch evenly, put it into a tube furnace, and keep it at 600°C for 3h under an argon atmosphere at a heating rate of 5°C / min Finally, the material is taken out to obtain a hard carbon composite material.

Embodiment 2

[0104] A preparation method of hard carbon composite material, comprising the following steps:

[0105] Weigh 300g of phenolic resin and stir to dissolve it in 600mL of absolute ethanol, add 3g of hexamethylenetetramine and 15g of phosphoric acid under stirring conditions, stir for 3h to completely dissolve the phenolic resin, then suction filter, and take the filtrate at 50 Dry in an oven at ℃; put the dried sample into a tube furnace, and carry out carbonization at 800°C for 3 hours at a heating rate of 2°C / min under an argon atmosphere, and the carbonized sample is placed in a ball mill at 300r / min Ball mill for 5 hours, then pass through a 300-mesh sieve; then mix the sieved material with 10g of medium-temperature coal tar pitch evenly, put it into a tube furnace, and keep it warm at 600°C at a heating rate of 5°C / min under an argon atmosphere After 2 hours, the material was taken out to obtain a hard carbon composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com