Multi-layer nested X-ray focus lens main power control assembling and adjusting device

A focusing mirror and X-ray technology, applied in the field of X-ray focusing mirror processing, can solve the problems of inability to guarantee the consistency of mass assembly process, inability to meet multi-layer nesting assembly, deformation of large-sized ultra-thin lenses, etc. Consistency and reliability, labor-saving, quick set-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

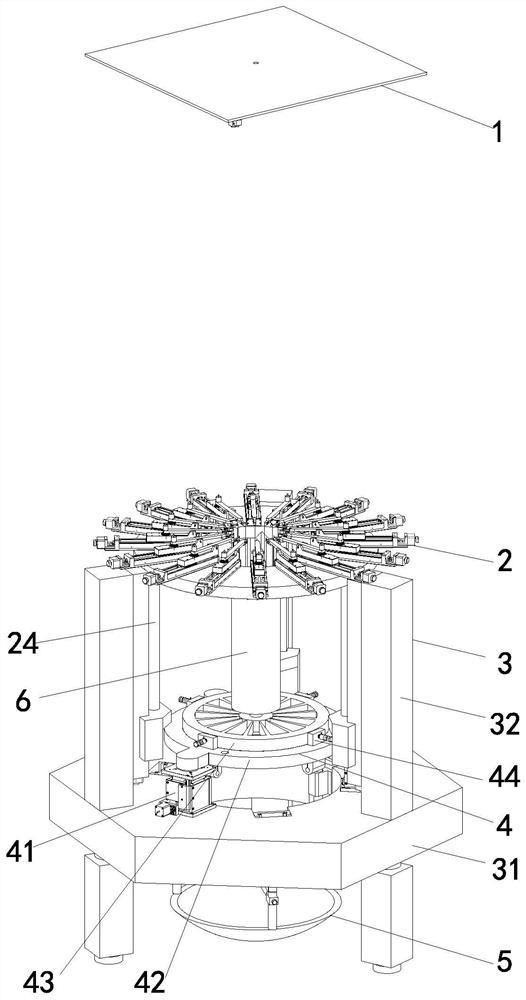

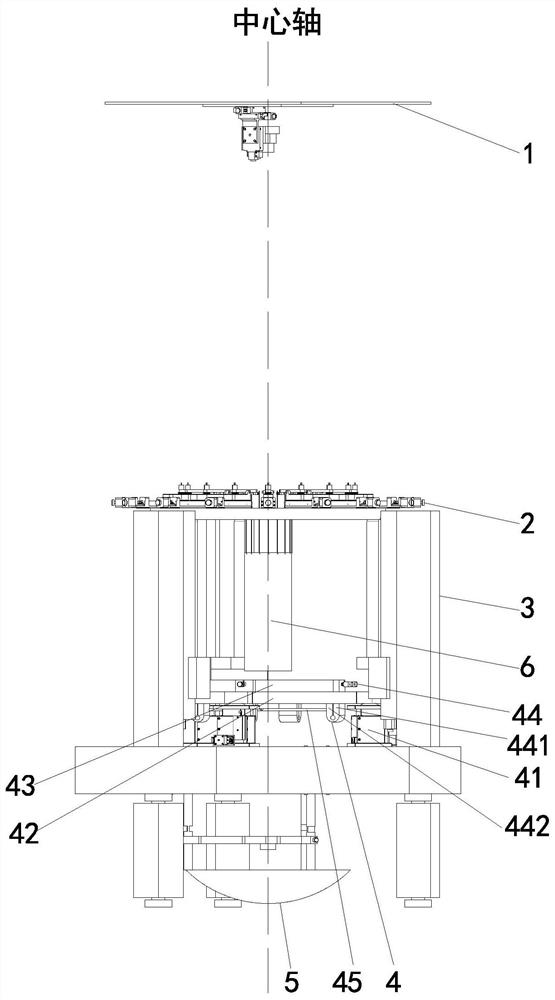

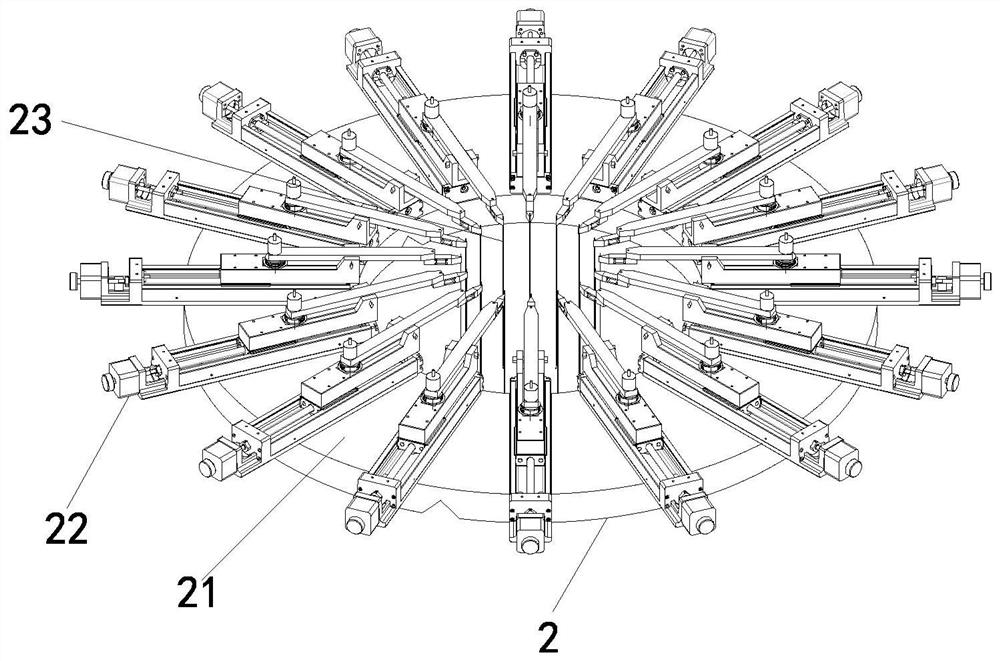

[0021] refer to Figure 12 As shown, the principle of the assembly and adjustment device: during the assembly and adjustment process, the lens barrel to be assembled is hoisted above the spider hub through the hoisting plate assembly. The light emitted by the point light source is reflected by the parabolic mirror to form a parallel beam. After being blocked by an aperture of a specific size, only light that matches the size of the lens barrel to be tested can enter the hub assembly. The light beam is reflected by the lens barrel and focused on the imaging plane of the camera placed 5.25 meters above. The system first measures the spot position of the reference mirror, then detects the pre-focus and back-focus spots of the lens barrel to be tested, compares the two and calculates the angle and position error. Then adjust the relative angle and position of the hub assembly and the new lens barrel until both focus on the same point. The horizontal and vertical positions of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com