Preparation method of germanium selenide nano material and application of germanium selenide nano material

A nanomaterial, germanium selenide technology, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve the problems of unsuitable industrial production, troublesome preparation methods, etc., and achieve the advantages of enrichment and conversion, excellent piezoelectricity Performance, good response to ultrasonic vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for preparing germanium selenide nanoparticles, comprising the following steps:

[0042] 0.4g GeI 4 Add 20mL oleylamine (OLA) into a 25mL three-necked flask in air, and magnetically stir at a speed of 250r / min, then vacuumize to -0.2MPa, and heat to 120°C for 30min;

[0043] Then inject 120 μL of selenourea, and the reaction mixture was heated at 240 °C under N 2 Flow down and reflux for 12 hours, cool to room temperature, wash with acetone, alcohol and deionized water in sequence, and dry to obtain germanium selenide nanoparticles, the thickness of the germanium selenide nanoparticles is 1-2 μm.

Embodiment 2

[0045] This embodiment provides a method for preparing germanium selenide nanosheets, comprising the following steps:

[0046]Grinding the germanium selenide nanoparticle material into a powder and passing through a 600-mesh sieve, adding it to ethanol for ultrasonication in an ice bath for 2 hours, centrifuging the obtained product at 8,000 rpm for 2 minutes, and drying by centrifugation to obtain germanium selenide nanosheets. The germanium selenide nanosheets have a length of 300-900 nm, which can be 300 nm, 500 nm, 700 nm, 800 nm, or 900 nm according to specific implementation conditions.

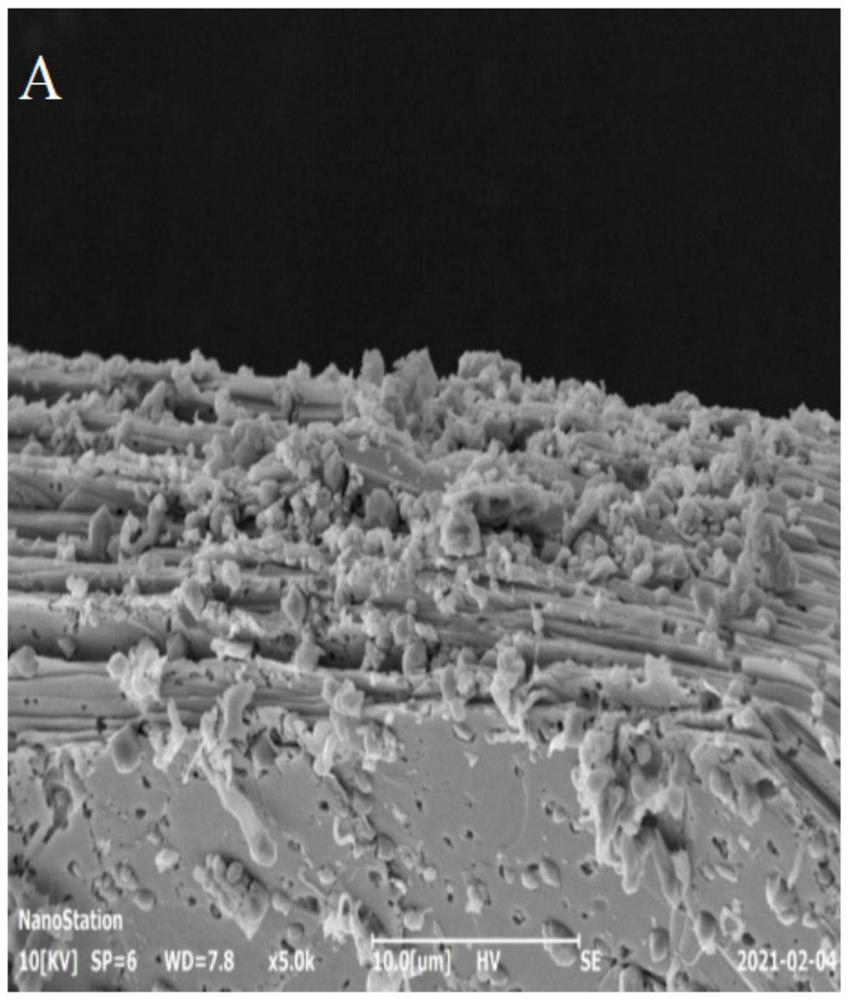

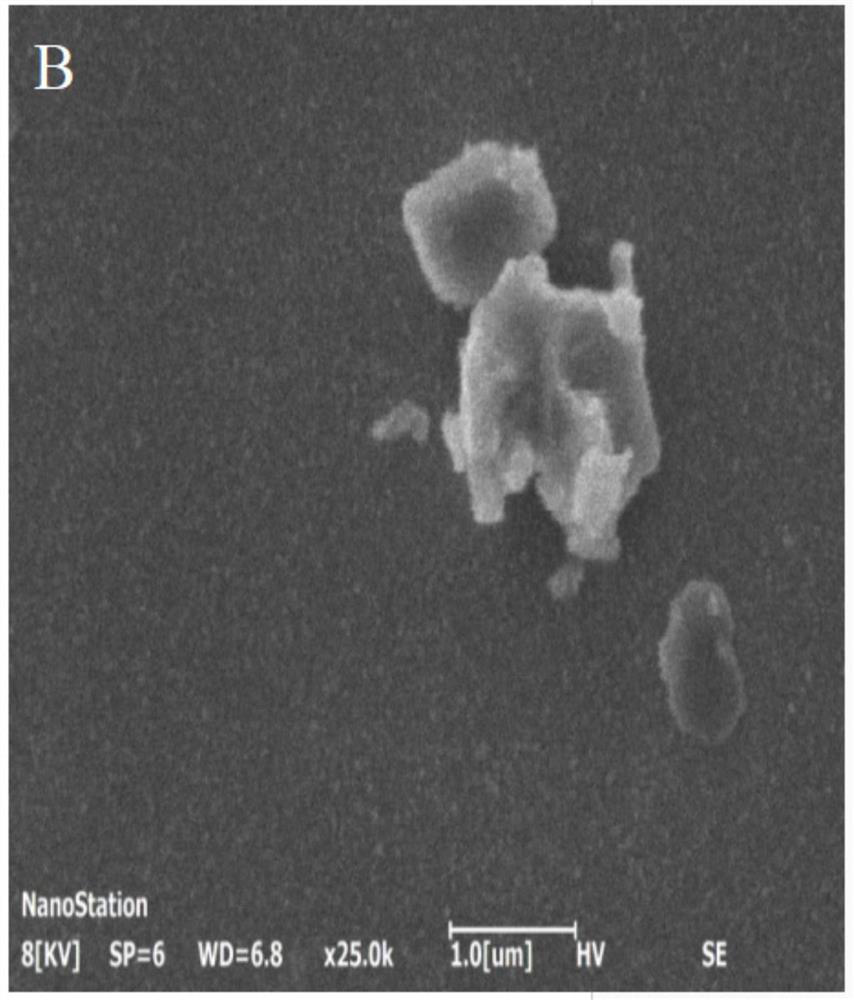

[0047] The germanium selenide nanoparticle and the germanium selenide nanosheet in embodiment 1 and embodiment 2 are carried out scanning electron microscope (SEM) analysis, as figure 1 and figure 2 As shown, it can be seen that the germanium selenide obtained in embodiment 1 is granular, and the germanium selenide obtained in embodiment 2 is flake.

[0048] Among the present inventi...

Embodiment 3

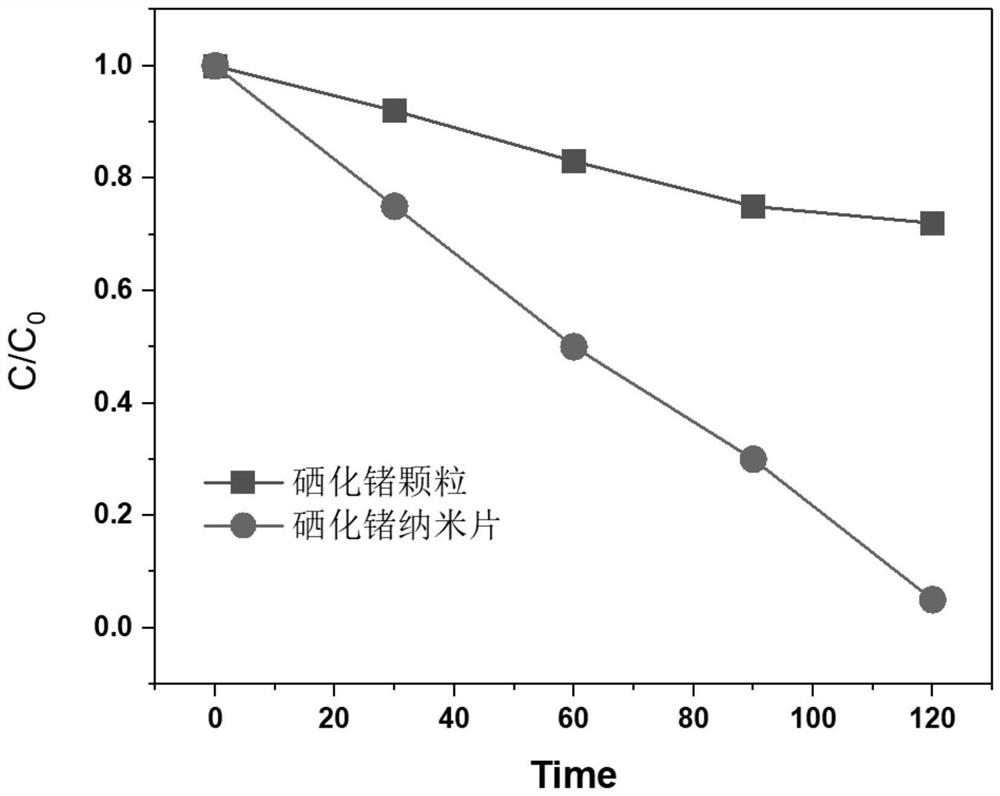

[0051] Put 50mg of germanium selenide nanoparticles in Example 1 into 100mL of deionized water containing 0.005mol / L of antibiotics, magnetically stir under dark conditions to reach adsorption-desorption equilibrium, and add 45kHz, 100W ultrasonic waves, respectively, for 0h , 1h, 2h, 3h, 4h and 5h, and a high-performance liquid chromatography (HPLC) with a UV detector was used to determine the concentration of antibiotics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com