High-power plasma gas purification device

A gas purification device and plasma technology, which is applied in gas treatment, separation methods, and separation of dispersed particles, can solve problems such as weak discharge current, high breakdown voltage, and human discomfort, so as to increase the effective discharge area and improve discharge efficiency. Power, the effect of improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

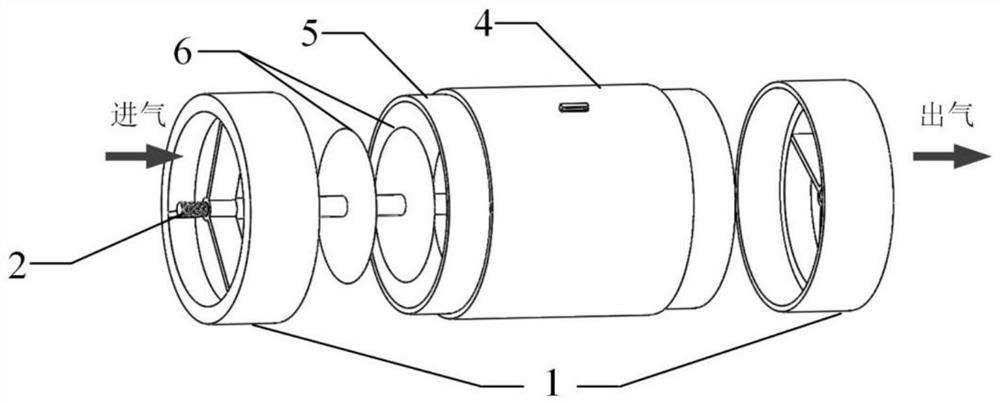

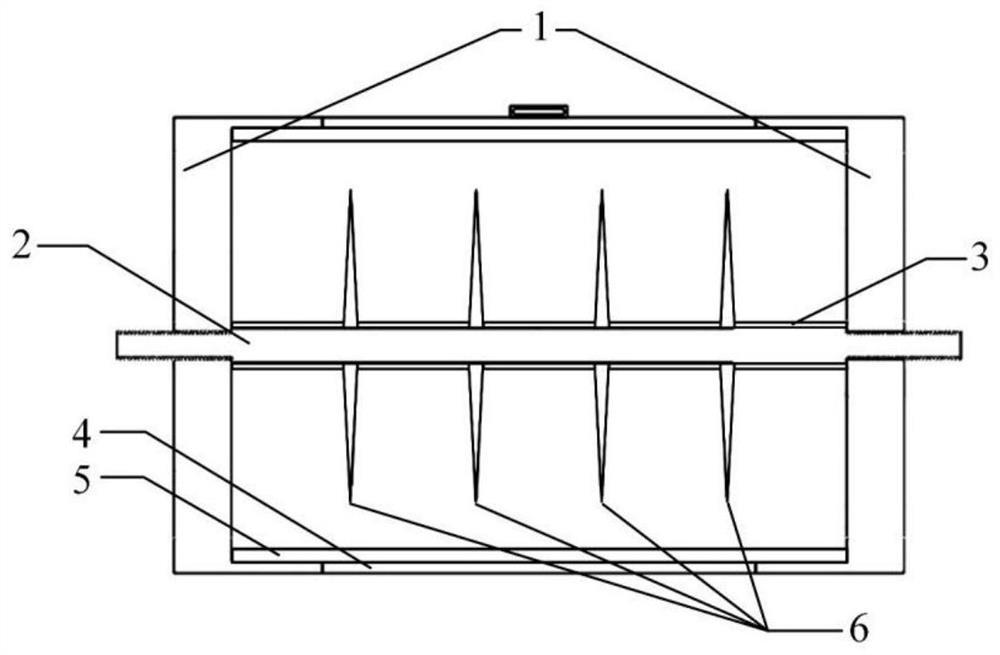

[0036] like figure 1 , figure 2 As shown, the high power plasma gas purification apparatus, including: insulating fastening member 1, metal shaft 2, metal ground casing 4, insulating dieter 5, and metal electrode 6, the metal electrode is a metal wafer electrode .

[0037] A metal wafer electrode is provided, the metal wafer electrode is provided, and the metal wafer electrode is attached to the metal shaft 2 by the perforation kit in which the center of the center is turned on by the metal shaft 2. .

[0038] The insulative dielectric cartridge 5 is located between the metal wafer electrode and the metal ground casing, forming a DBD discharge structure, avoiding discharge conversion into an arc or spark form, and reduces the voltage amplitude applied to the high voltage electrode, resulting in only a partial region discharge. The insulating dielectric cartridge is preferably a high temperature resistant to high temperature resistance. According to the available voltage amplitude,...

Embodiment 2

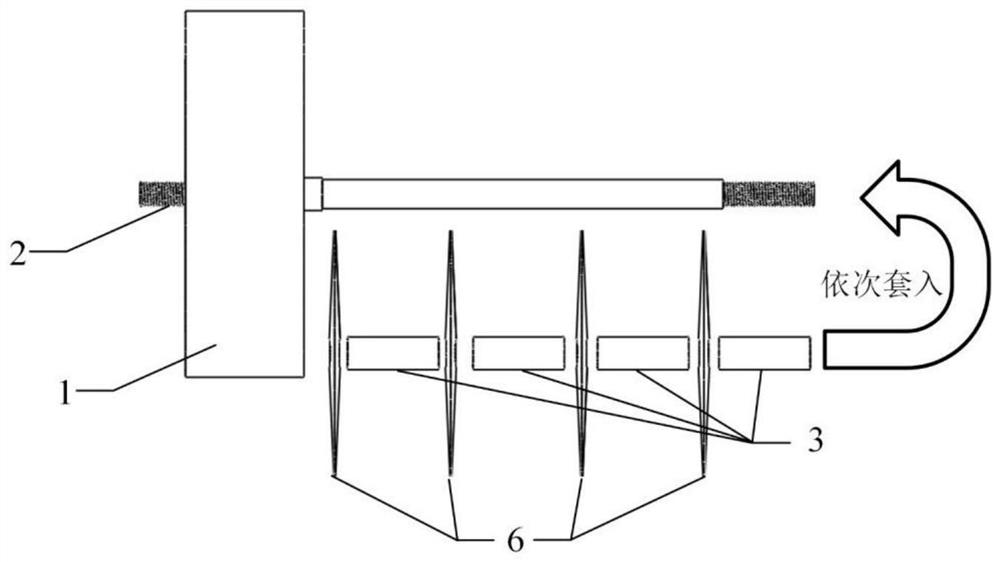

[0046] like image 3 As shown, in fact, in the present embodiment, in the present embodiment, the metal wafer electrode and the metal shaft 2 are not integrated, but the detachable structure. Each individual metal wafer electrode is spaced apart by the metal sleeve 3 and conducts, the metal wafer electrode and the metal sleeve are sequentially set on the metal shaft 2. By changing the length of the metal sleeve 3, the number of the serial metal wafer electrodes can be changed. When the environmental dust content is more, consider the cleaning of the device to maintain the discharge efficiency, this detachable structure of the electrode.

Embodiment 3

[0048] Unlike Example 1, in the present embodiment, the metal wafer electrode is placed with a metal shaft. By changing the position of the center hole of the insulating fastening member, the distance from the inner wall of the metal wafer electrode and the insulating medium can be adjusted, that is, the discharge gap between the electrode and the insulating dielectric bar, such as Figure 4 Indicated. In the case of limited power output capability, the eccentric placing facilitates control discharge in the same discharge cycle. Since the area electric field in the gap is higher, it will be discharged, so that the discharge is not limited to a moment, and can reduce discharge The resulting peak current reduces the parameter requirements of the power supply; the area of the gap, due to the low electric field, after discharging, the discharge current can be eliminated, and the average power in the entire discharge cycle can not be reduced The active ingredient produced by the disch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Edge thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Edge thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com