Novel high-molecular plug plate for tunnel secondary lining

A technology of polymer and plug plate, applied in tunnel lining, tunnel, wellbore lining and other directions, can solve the problems of complicated steps, leakage of slurry, difficult to guarantee the installation position, etc., to improve the speed of installation and disassembly, the overall structure is simple, and the The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

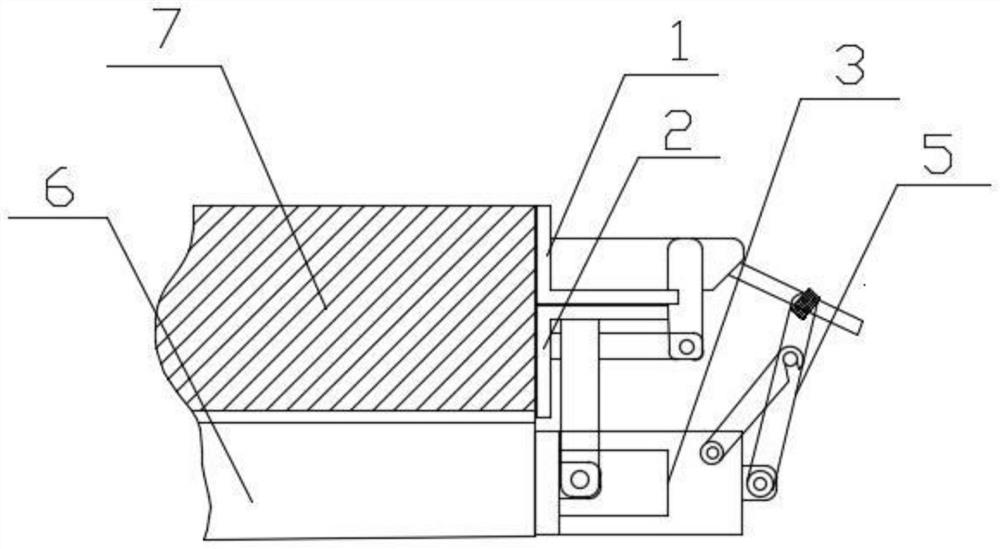

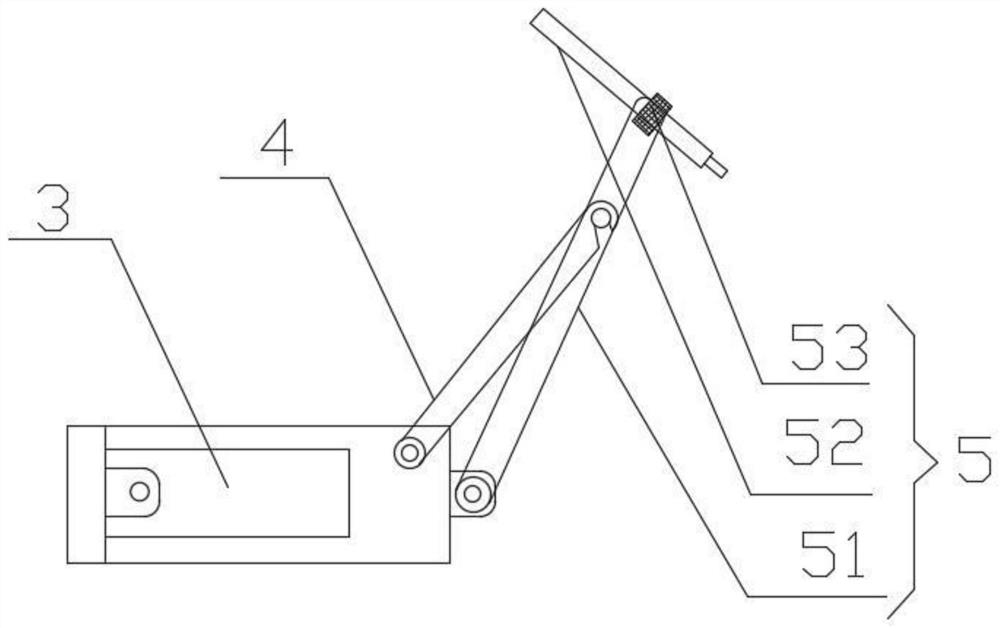

[0027] combine Figure 1 to Figure 6 , the present invention provides a new type of polymer plug plate for the second lining of the tunnel, comprising an upper formwork 1, a lower formwork 2 and a support mechanism, the upper formwork 1 and the lower formwork 2 are hinged, the lower formwork 2 and the support The mechanism is hinged, and the support mechanism is detachably connected with the upper template 1; the support mechanism includes a support seat 3, a support rod 5 and a connecting hanging plate 4, one end of the support seat 3 is fixedly connected with the trolley 6, and the other end Hinged with the support rod 5, the other end of the support rod 5 is threadedly connected with the upper formwork 1, one end of the connecting hanging plate 4 is fixedly arranged on the support seat 3, and the other end is connected to the support b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com