Photovoltaic hydrogen production system control method based on incremental conductance method

A conductance incremental method and control method technology, applied in the field of photovoltaic hydrogen production system control based on the conductance incremental method, can solve the problems of clean energy consumption with fluctuating power generation, hindering the safety and stability of the power grid, and difficulty in continuous and reliable power supply, etc. Achieve the effects of adapting to power fluctuations, reducing energy consumption for hydrogen production, and improving system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

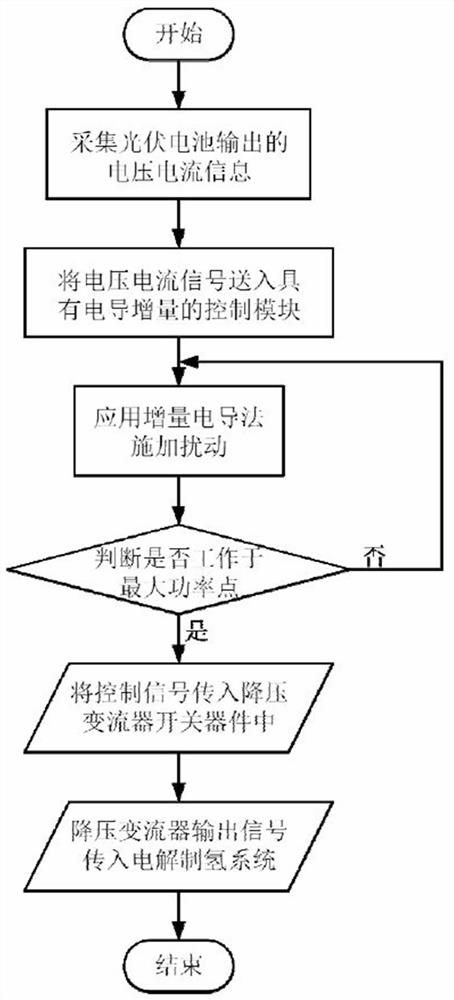

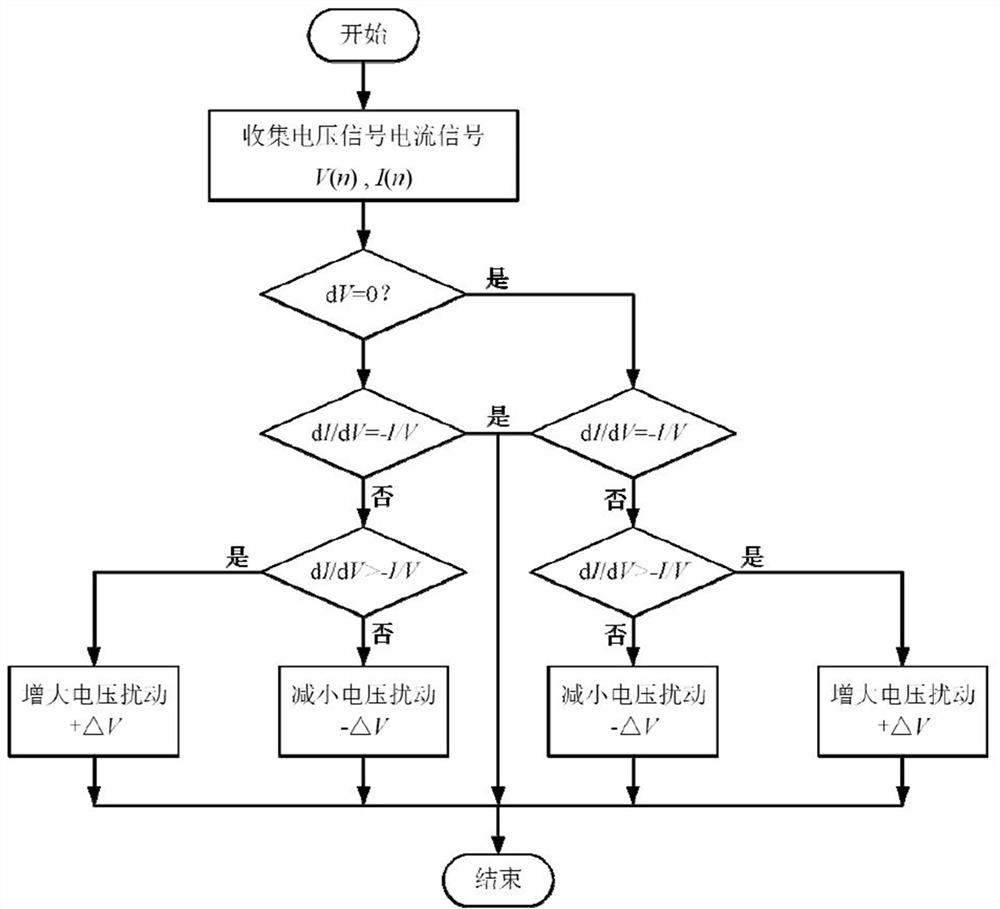

[0070] The specific process is attached figure 1 As shown, the present invention proposes a photovoltaic hydrogen production system control method based on the conductance incremental method. The method is based on the step-down converter control, and can quickly determine the maximum power point for the power fluctuation problem caused by photovoltaics due to changes in light temperature. At the same time, it can well adapt to the electrolysis system that requires high current and low voltage working environment and can well adapt to power fluctuations, and can improve the hydrogen production efficiency while ensuring the stable operation of the system.

[0071] A control method for a photovoltaic hydrogen production system based on the conductance incremental method includes the following steps:

[0072] Step 1. Collect voltage and current information output by photovoltaic cells under different working environments;

[0073] Step 2. Analyze the photovoltaic step-down conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com