Preparation method of hydrogen abstracting type photoinitiator based on higher fatty acid and product thereof

A technology of higher fatty acid and photoinitiator, applied in the direction of organic chemistry, etc., can solve the problems of odor toxicity, migration, etc., and achieve the effects of increasing molecular weight, easy operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

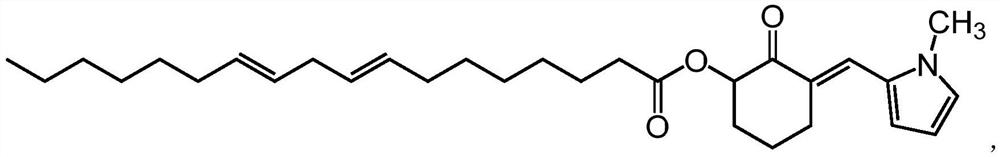

Embodiment 1

[0042] Prepare a hydrogen abstraction type photoinitiator based on higher fatty acids, the specific preparation method is as follows:

[0043] 1. Dissolve 28.2g (0.1mol) of oleic acid and 12.7g (0.1mol) of oxalyl chloride in N,N-dimethylformamide (DMF) solvent, and react at 140°C for 24 hours to obtain the acid chloride compound Finally (determined by pointing the plate), add 7.4g (0.1mol) of hydroxyacetone, add 0.635g of triethylamine as a catalyst, and use triethylamine to adjust the pH value of the system to neutral after reacting at 70°C for 5 hours. , point plate through the column purification, to obtain the intermediate product.

[0044] 2, the intermediate product of 16.6g (0.05mol) and the 2-pyrrole carboxaldehyde of 9.8g (0.1mol) are under ethanol solvent, add dropwise 3~5 drops of NaOH aqueous solution (0.5g NaOH and 9.5g solution formed by water configuration), adjust the pH value to 13, and react for 3 hours under the protection of nitrogen at 30°C, then use an i...

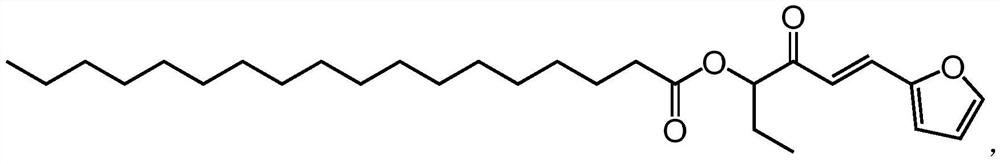

Embodiment 2

[0051] Prepare a hydrogen abstraction type photoinitiator based on higher fatty acids, the specific preparation method is as follows:

[0052] 1. Dissolve 28.4g (0.1mol) of octadecanoic acid and 10.2g (0.1mol) of 3-hydroxy-2-pentanone in acetonitrile solution, add 2mL of concentrated sulfuric acid as a catalyst, and react at 70°C for 2 hours , cooled to precipitate a solid, washed with water, and dried with anhydrous sodium sulfate to obtain an intermediate product.

[0053] 2. The furfuraldehyde of the intermediate product and 9.6g (0.1mol) is added in the ethanol solvent for dissolving, and 3-5 drops of a mass fraction of 5% NaOH aqueous solution (0.5g of NaOH and 9.5g of water are configured to obtain) are added dropwise to adjust The pH value was 13, reacted under the protection of nitrogen at 70°C for 3 hours, continued the reaction in an ice bath for 3 hours, and precipitated a pale yellow solid, washed with water, and dried over anhydrous sodium sulfate to obtain a hydr...

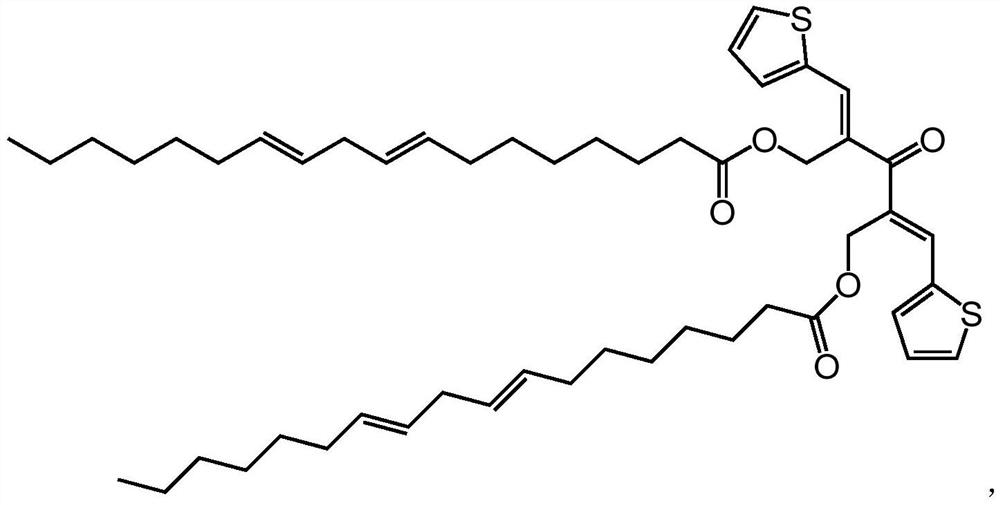

Embodiment 3

[0058] Prepare a hydrogen abstraction type photoinitiator based on higher fatty acids, the specific preparation method is as follows:

[0059] 1. Dissolve 56g (0.2mol) of linoleic acid and 11g (0.1mol) of 1.5-hydroxypentanone in acetonitrile solution, add concentrated sulfuric acid as a catalyst, react at 70°C for 2 hours, cool to precipitate solids, and water After washing, it was dried over anhydrous sodium sulfate to obtain an intermediate product.

[0060] 2. Add the intermediate product and 22.4 g (0.2 mol) of thiophene formaldehyde into the ethanol solvent, add dropwise 3 to 5 drops of 5% NaOH aqueous solution (0.5 g of NaOH and 9.5 g of water), and adjust the pH value After reacting for 3 hours under the protection of nitrogen at 70°C, use an ice bath to continue the reaction for 3 hours, and a light yellow solid precipitates out. The product is washed with water and dried over anhydrous sodium sulfate to obtain a hydrogen abstraction photoinitiator S-1 based on higher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com