Denitrification wood carbon source carbon release amount regulation and control method based on reducing sugar yield, wood carbon source and application

A sugar yield and denitrification technology, applied in chemical instruments and methods, special data processing applications, anaerobic digestion treatment, etc., can solve the problems of reduction, poor reaction effect, secondary pollution service life, etc., to ensure the treatment effect , easy to control, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

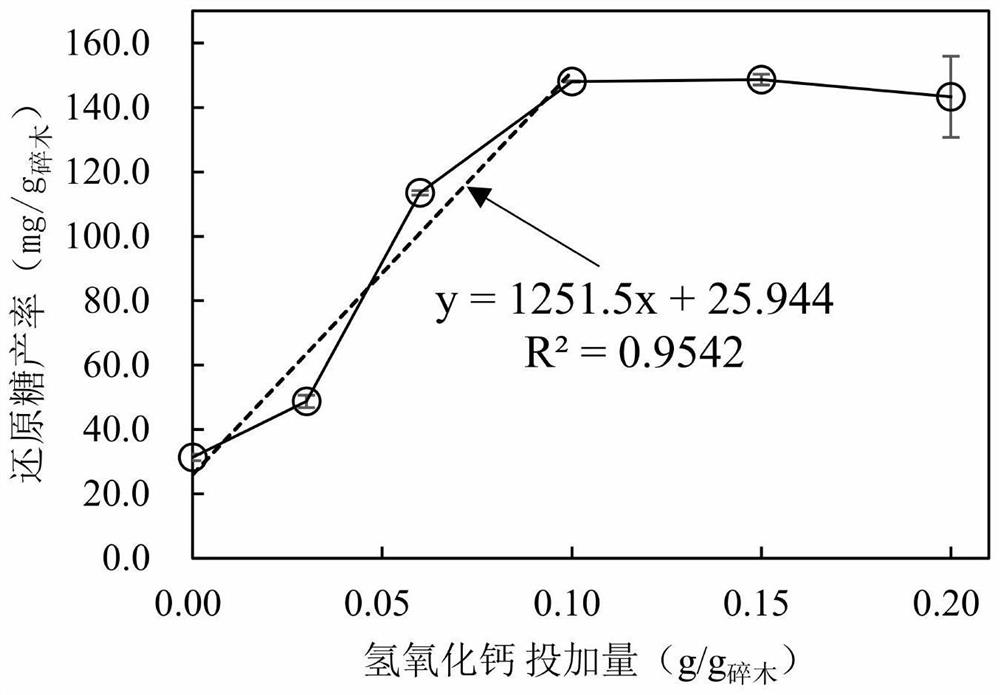

[0092] build equation

[0093] (1) Choose 0.1-1.0mm poplar wood chips as raw materials, weigh 6 parts, each 5.0g, add 0.0, 0.03, 0.06, 0.10, 0.15 and 0.20g / g respectively 碳源 Ca(OH) 2 , control the solid-liquid ratio to 1:10, and react at 90°C and 150rmp for 24h. After the reaction, perform repeated suction filtration and water washing until the filtrate is neutral, and dry the solid sample at 60°C.

[0094] The prepared samples were hydrolyzed with specific enzymes, adding 20FPU of cellulase and 20CBU of β-glucosidase per gram of sample, hydrolyzing at 50°C for 3 days, using the DNS method to measure the reducing sugar content in the filtrate, and The reducing sugar yield was calculated and the results are shown in Table 1.

[0095] Table 1 The reducing sugar yield of chip wood under the condition of calcium hydroxide dosage

[0096]

[0097] Establish reducing sugar yield y 1 and Ca(OH) 2 dosage x 1 relationship, the curve is as figure 1 As shown, according to the f...

Embodiment 2

[0104] Determination of the Target Reducing Sugar Yield of Woody Carbon Sources under the Water Environment Conditions to be Tested

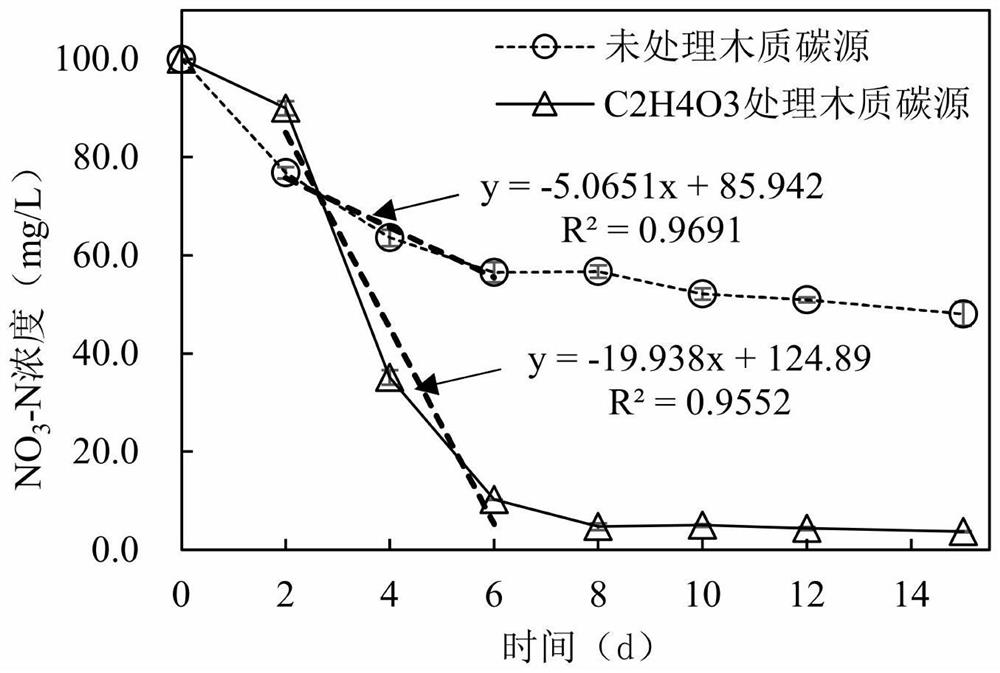

[0105] To simulate the environmental conditions of nitrate concentration of 100mg / L, temperature of 25°C and pH value of 7, 5.0g of untreated

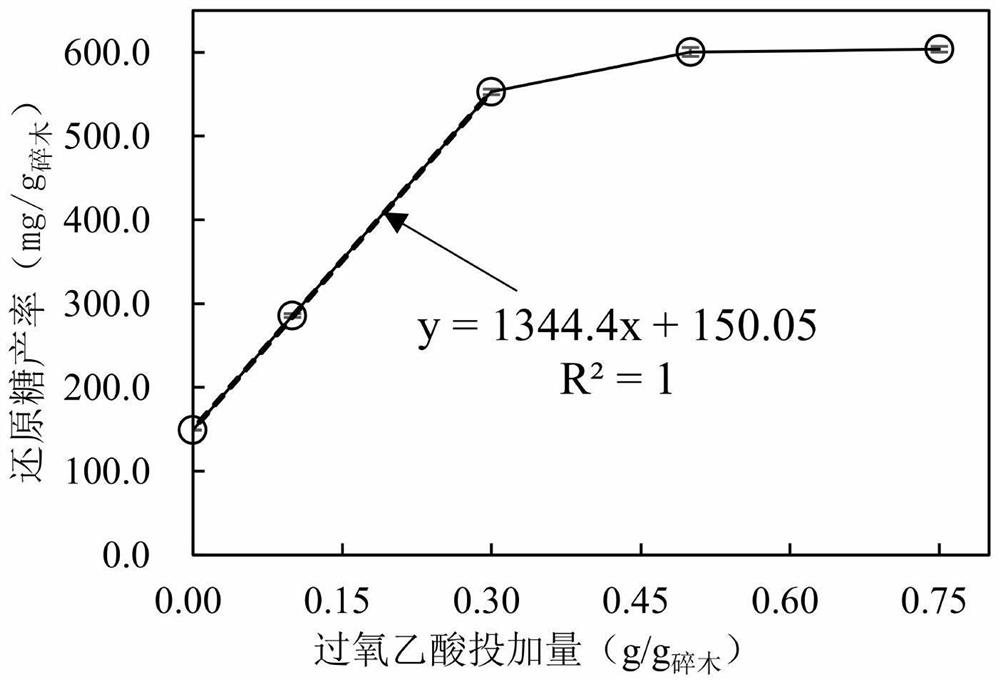

[0106] Processing and C 2 h 4 o 3 Treatment of woody carbon sources for denitrification batch trials. After testing, C 2 h 4 o 3 The reducing sugar yield of processing woody carbon source is higher, which is 553.0mg / g 碳源 , is the reducing sugar yield of untreated woody carbon source (31.3mg / g 碳源 ) 17.7 times.

[0107] The specific process of the denitrification test is as follows: Weigh 5.0g of woody carbon source into a 500mL glass bottle, add 400mL of simulated nitrate sewage, and the NO of sewage 3 - The -N concentration is 100.0 mg / L and the pH value is 7; the sample bottle is aerated with nitrogen for 20 minutes, sealed with a rubber stopper, and placed in a biochemical incubator for culti...

Embodiment 3

[0110] Determining the woody carbon source for the required carbon release under the water environment conditions to be tested

[0111] Obtaining woody carbon source target reducing sugar yield in embodiment 2 is 122.1mg / g 碎木 , according to the interval obtained in Example 1, the target reducing sugar yield is within the first reducing sugar interval range, so the first equation is used to calculate, and Ca(OH) is obtained during the preparation of woody carbon source 2 The dosage is 0.077g Ca(OH) 2 / g 碳源 , and reacted at 90°C for 24 hours to obtain a woody carbon source with the desired amount of carbon released.

[0112] To simulate the environmental conditions of nitrate concentration of 100mg / L, temperature of 25°C and pH value of 7, 5.0g of untreated and Ca(OH) 2 Treatment of woody carbon sources for verification trials.

[0113] Weigh 5.0g of woody carbon source into a 500mL glass bottle, add 400mL of simulated nitrate sewage, and the NO of sewage 3 - The -N concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com