Cobalt tungstate material synthesized under assistance of sodium citrate, and preparation method and application thereof

A technology of sodium citrate and cobalt tungstate, applied in chemical instruments and methods, cobalt compounds, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of slowing down the nucleation rate of precursors and crystal growth, affecting the final product morphology and other issues to achieve the effect of improving the sonocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1CoWO 4 preparation of

[0019] First, Co(NO 3 ) 2 ·6H 2 O (5mmol) was dissolved in 30mL deionized water to obtain an aqueous solution labeled A, and Na 2 WO 4 2H 2 O (5mmol) was dissolved in 30mL deionized water, marked as solution B; A and B were mixed, stirred magnetically at room temperature for 0.5h; then ultrasonically reacted for 0.5h and then the homogeneous suspension was sealed in a 100ml Teflon-lined container In an autoclave, keep at 180°C for 24h, then cool down to room temperature naturally. Suction filtration and washing several times, the precipitate was collected by centrifugation, and finally vacuum-dried at 60°C for 2h. The product CoWO 4 , denoted as CoWO 4 -0.

Embodiment 2

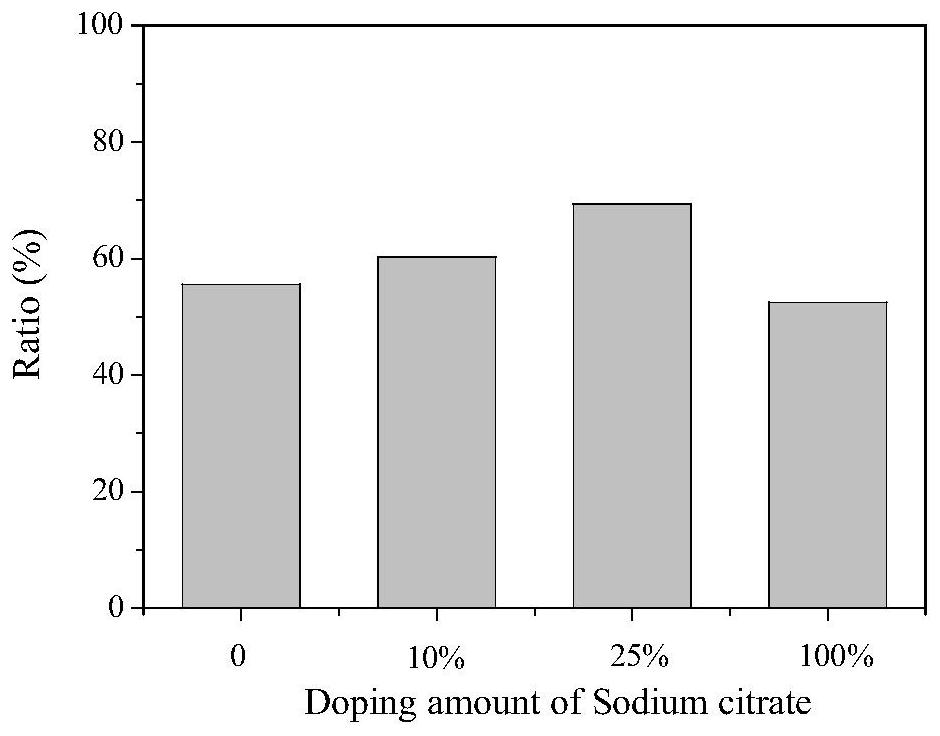

[0020] The preparation of the cobalt tungstate assisted synthesis of embodiment 2 sodium citrate

[0021] First, Co(NO 3 ) 2 ·6H 2 O (5mmol) was dissolved in 30mL deionized water to obtain an aqueous solution labeled A, and Na 2 WO 4 2H 2 O (5mmol) was dissolved in 30mL of deionized water, marked as B solution; A and B were mixed, and different masses of sodium citrate (0.1474g, 0.3676g, 0.7353g, 1.475g) were added thereto, and magnetically stirred at room temperature for 0.5 h; ultrasonically reacted for 0.5 h, then sealed the homogeneous suspension in a 100 ml polytetrafluoroethylene-lined autoclave, kept at 180° C. for 24 h, and then cooled naturally to room temperature. Suction filtration and washing several times, centrifugation to collect the precipitate, and finally vacuum drying at 60°C for 2 hours to obtain the product CoWO 4 , denoted as CoWO 4 -1, CoWO 4 -2, CoWO 4 -3, CoWO 4 -4.

Embodiment 3

[0022] The characterization analysis of the cobalt tungstate acoustic catalyst of embodiment 3 sodium citrate auxiliary synthesis

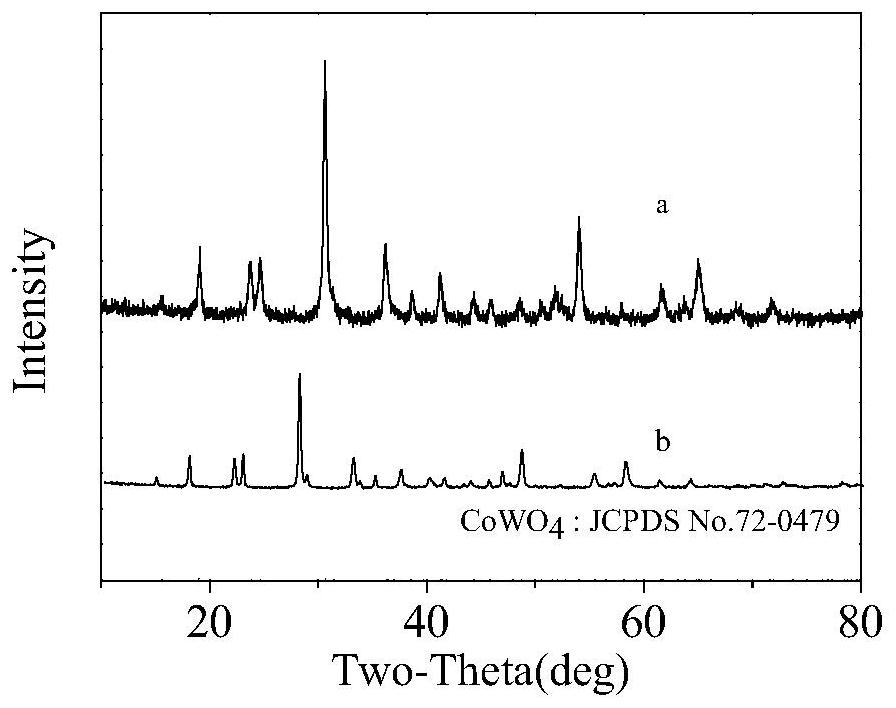

[0023] figure 1 Synthetic CoWO 4 and CoWO synthesized assisted by sodium citrate 4 XRD spectrum of -2 sample. The diffraction peaks in the figure are strong and sharp, indicating that the synthesized product has high crystallinity.

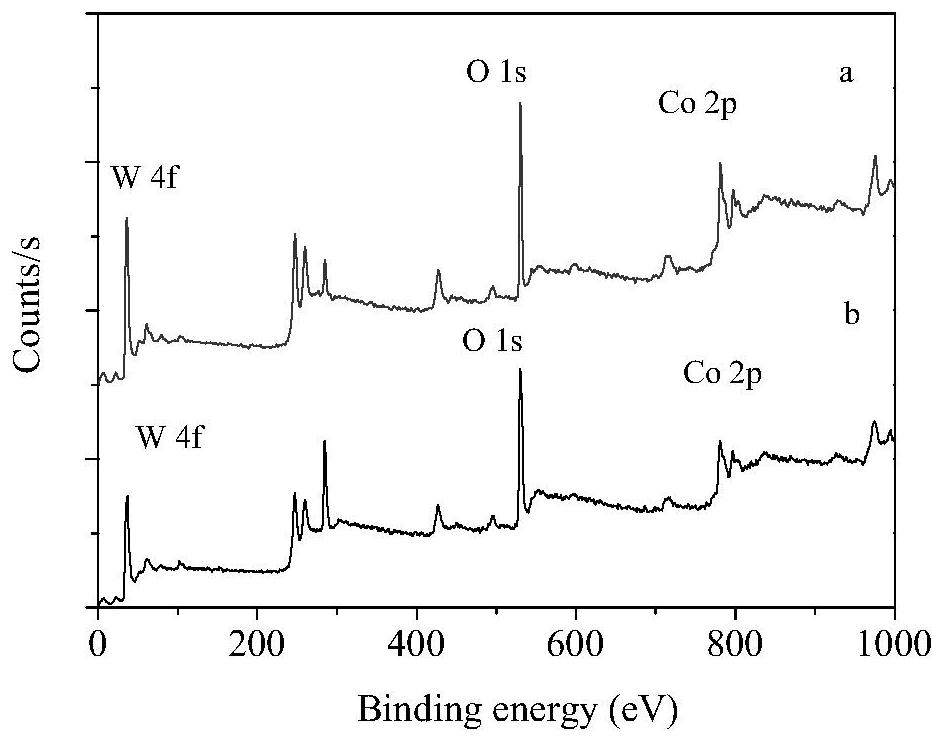

[0024] figure 2 Synthetic CoWO 4 and CoWO synthesized assisted by sodium citrate 4 XPS spectrum of -2 samples. The high-resolution spectral signals of W4f, Co2p, and O1s appear at 50.3eV, 812.3eV, and 545.3eV, respectively, proving that the valences of W, Co, and O in the compound are +6, +2, and -2, respectively. Among them, the high-resolution spectral signals of each element in the cobalt tungstate nanomaterial synthesized by adding sodium citrate are also very close to the description in the literature, indicating that the product synthesized by adding sodium citrate is still CoWO 4 nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com