Low-pressure softened composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and low-pressure technology, which is applied in the field of water purification, can solve the problems of the reaction monomer solution staying on the membrane, the separation layer of the composite membrane cannot be controlled, and the thickness is difficult to accurately grasp, so as to save the amount of raw materials used and the process is simple. , the effect of improving flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Active monomer solution preparation

[0024] Dissolve 0.25% polyethyleneimine PEI 70000 in 99.75% deionized water and stir to make a uniform polyethyleneimine PEI solution with a concentration of 0.25%; in addition, dissolve 0.15% trimesoyl chloride TMC in 99.9% n-hexane to obtain a concentration of 0.15% % trimesoyl chloride TMC solution.

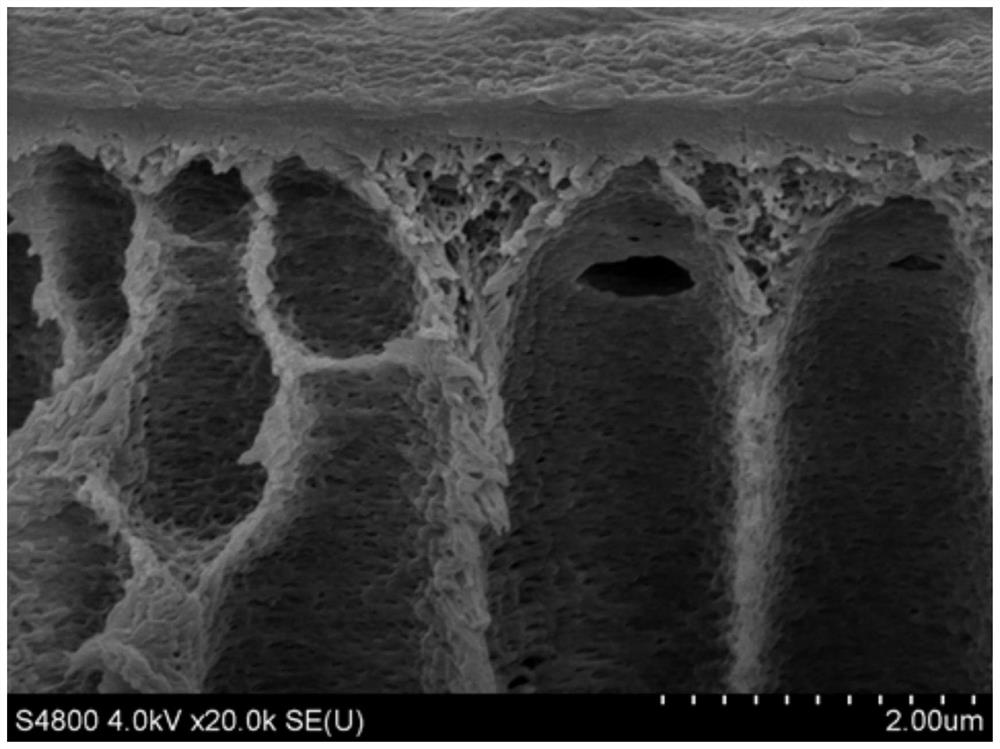

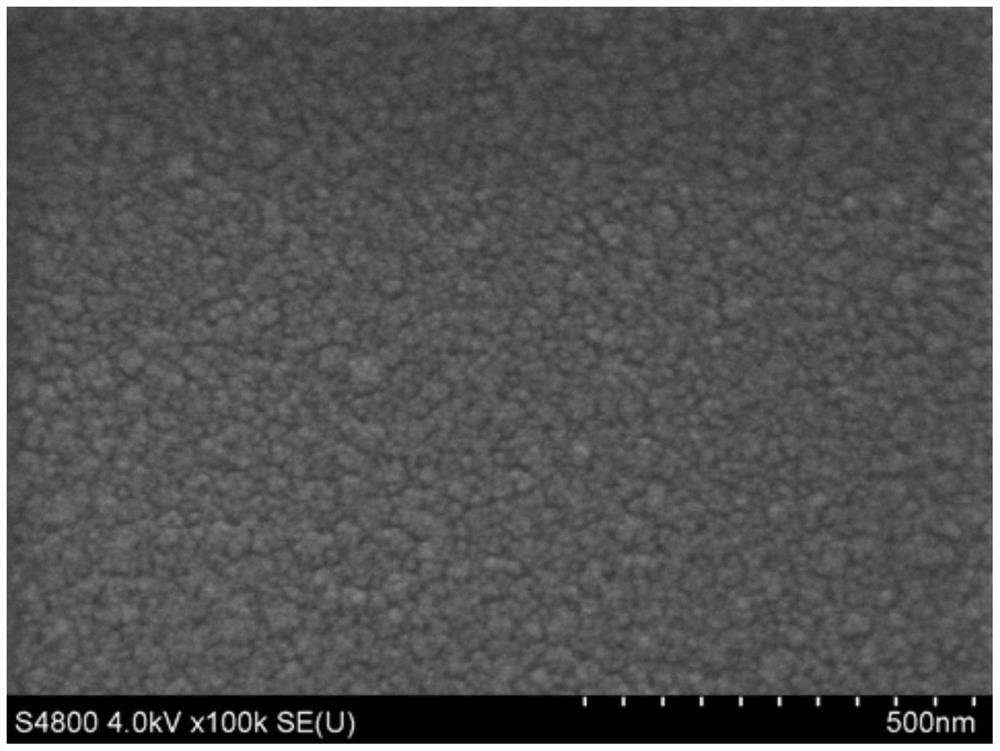

[0025] 2. Electrostatic spray deposition film separation layer

[0026] 1) Immerse the ultrafiltration support layer in the additive 0.1 sodium dodecyl sulfate SDS solution, soak for 10 minutes, take it out and dry it until there is no moisture on the surface;

[0027] 2) Put the above two kinds of active monomer solutions into the two containers of the electrostatic spray equipment respectively, the spray rate on the polyethyleneimine PEI70000 side was fixed at 3.6mL / h, the distance between the needle and the collector was 10cm, and the applied The voltage is +11.2KV, the spray rate of trimesoyl chloride TMC is 3.6mL / h, the di...

Embodiment 2

[0038] 1. Active monomer solution preparation

[0039] Dissolve 0.25% polyethyleneimine PEI 100000 in 99.75% deionized water and stir to make a uniform polyethyleneimine PEI solution with a concentration of 0.25%; in addition, dissolve 0.15% trimesoyl chloride TMC in 99.9% n-hexane to obtain a concentration of 0.15% % trimesoyl chloride TMC solution.

[0040] 2. Electrostatic spray deposition film separation layer

[0041] 1) Immerse the ultrafiltration support layer in the additive 0.1 sodium dodecyl sulfate SDS solution, soak for 10 minutes, take it out and dry it until there is no moisture on the surface;

[0042] 2) Put the above two active monomer solutions into the two containers of the electrostatic spray equipment respectively, the spray rate on the polyethyleneimine PEI100000 side was fixed at 3.6mL / h, the distance between the needle and the collector was 10cm, and the applied The voltage is +12.8KV, the spray rate of trimesoyl chloride TMC is 3.6mL / h, the distance ...

Embodiment 3

[0045] 1. Active monomer solution preparation

[0046] Dissolve 0.25% polyethyleneimine PEI 100000 in 99.75% deionized water and stir to make a uniform polyethyleneimine PEI solution with a concentration of 0.25%; in addition, dissolve 0.15% trimesoyl chloride TMC in 99.9% n-hexane to obtain a concentration of 0.15% % trimesoyl chloride TMC solution.

[0047] 2. Electrostatic spray deposition film separation layer

[0048] 1) Immerse the ultrafiltration support layer in the additive 0.1 sodium dodecyl sulfate SDS solution, soak for 10 minutes, take it out and dry it until there is no moisture on the surface;

[0049] 2) Put the above two active monomer solutions into the two containers of the electrostatic spray equipment respectively, the spray rate on the polyethyleneimine PEI100000 side was fixed at 3.6mL / h, the distance between the needle and the collector was 10cm, and the applied The voltage is +12.8KV, the spray rate of trimesoyl chloride TMC is 3.6mL / h, the distance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com