Compression-resistant flame-retardant carton and preparation method thereof

A flame retardant, carton technology, used in papermaking, paper, packaging paper, etc., can solve the problems of flame retardant carton not having a good flame retardant effect, inability to achieve flame retardant, damage to carton items, etc., to improve flame retardant sound insulation effect, improve the effect of flame retardant, improve the effect of compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

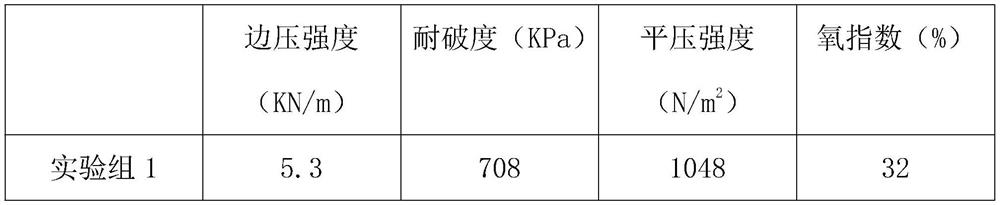

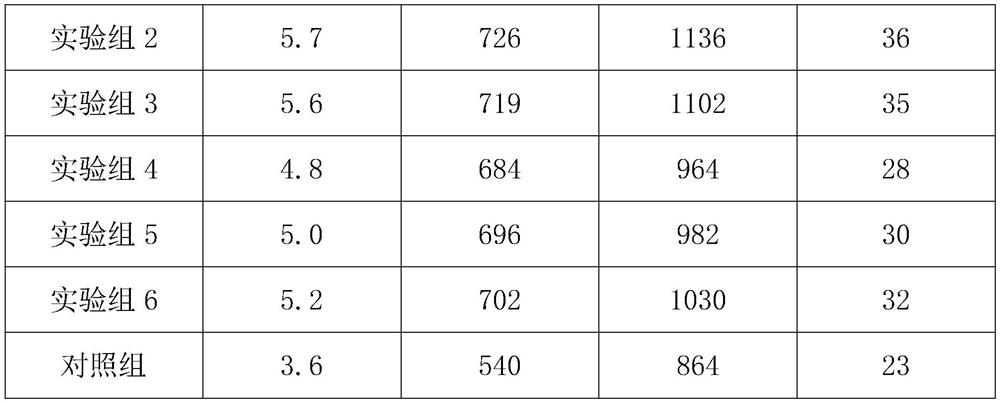

Examples

Embodiment 1

[0023] The invention provides a pressure-resistant and flame-retardant carton. The pressure-resistant and flame-retardant carton includes the following raw materials in parts by weight: 60 parts of bamboo pulp, 40 parts of wood pulp, 30 parts of modified straw fiber, and modified coconut shell fiber. 25 parts, 3 parts of flame retardant, 10 parts of modified diatomite and 2 parts of additives.

[0024] In a preferred embodiment, the flame retardant is a mixture of modified talc powder, sodium silicate and nano-titanium oxide, and the weight percentage of the modified talc powder, sodium silicate and nano-titanium oxide is 1:1.7 :2.

[0025] In a preferred embodiment, the auxiliary agent is calcium stearate or petroleum hydrocarbon wax, and the particle diameter of the modified diatomite is 3-6mm.

[0026] A method for preparing a pressure-resistant and flame-retardant carton, the specific preparation steps are as follows:

[0027] Step 1: Preparation of modified straw fibers...

Embodiment 2

[0036] The invention provides a pressure-resistant and flame-retardant carton. The pressure-resistant and flame-retardant carton includes the following raw materials in parts by weight: 80 parts of bamboo pulp, 60 parts of wood pulp, 40 parts of modified straw fiber, and modified coconut shell fiber. 33 parts, 6 parts of flame retardant, 15 parts of modified diatomite and 4 parts of additives.

Embodiment 3

[0038]Different from Examples 1 and 2, the present invention provides a pressure-resistant and flame-retardant carton, which includes the following raw materials in parts by weight: 100 parts of bamboo pulp, 80 parts of wood pulp, modified 50 parts of straw fiber, 40 parts of modified coconut shell fiber, 8 parts of flame retardant, 20 parts of modified diatomite and 6 parts of auxiliary agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap