Carbon/molybdenum disulfide-nitrogen-rich molybdenum nitride composite material, preparation and electro-catalytic hydrogen evolution application thereof

A technology of molybdenum disulfide and molybdenum nitride, which is applied in electrodes, electrolytic components, and electrolytic processes, can solve the problems of inability to adapt to high current density electrolysis of water for hydrogen production, insufficient catalytic efficiency, and low catalytic hydrogen evolution efficiency. The effect of improving the output capacity, improving the electrochemical performance, and improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

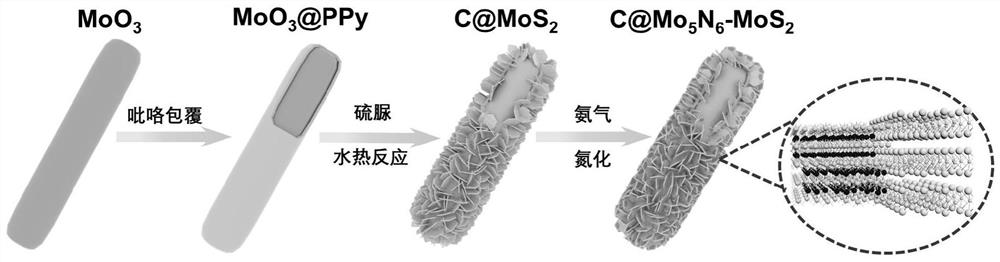

[0051] A carbon / molybdenum disulfide-nitrogen-rich molybdenum nitride composite electrochemical catalyst material, the schematic diagram of its synthesis process is shown in figure 1 , the specific preparation method comprises the following steps:

[0052] 1) 320mg MoO 3 Add 320mL water, mix and ultrasonically disperse evenly to get MoO 3 Dispersion liquid; Dissolve 650mg of ammonium persulfate in 80mL of water to prepare uniform ammonium persulfate solution; Dilute the obtained MoO 3 The dispersion was treated in an ice-water bath so that the temperature of the solution was kept at 4°C, and then 400 microliters of pyrrole monomer (Py) was added to the dispersion, and then ammonium persulfate solution was added dropwise; Water bath reaction (4°C), the obtained product was washed several times with deionized water and dried to obtain molybdenum oxide nanowires coated with polypyrrole;

[0053] 2) ultrasonically disperse 160 mg of the obtained molybdenum oxide nanowires coate...

Embodiment 2

[0061] A carbon / molybdenum disulfide-nitrogen-rich molybdenum nitride composite electrochemical catalyst material, the preparation method of which comprises the following steps:

[0062] 1) 320mg MoO 3 Add 320mL water, mix and ultrasonically disperse evenly to get MoO 3 Dispersion liquid; Dissolve 650mg of ammonium persulfate in 80mL of water to prepare uniform ammonium persulfate solution; Dilute the obtained MoO 3 The dispersion was treated in an ice-water bath so that the temperature of the solution was maintained at 3°C, and then 400 microliters of pyrrole monomer (Py) was added to the dispersion, and then ammonium persulfate solution was added dropwise; after the addition was completed, the temperature of the solution was maintained for 5 hours. Reacting in an ice-water bath (3° C.), washing the resulting product several times with deionized water and drying to obtain molybdenum oxide nanowires coated with polypyrrole;

[0063] 2) 160 mg of the obtained polypyrrole-coat...

Embodiment 3

[0068] A carbon / molybdenum disulfide-nitrogen-rich molybdenum nitride composite electrochemical catalyst material, the preparation method of which comprises the following steps:

[0069] 1) 1mg MoO 3 Add 1mL water, mix and ultrasonically disperse evenly to get MoO 3 Dispersion liquid; Dissolve 650mg of ammonium persulfate in 80mL of water to prepare uniform ammonium persulfate solution; Dilute the obtained MoO 3 The dispersion was treated in an ice-water bath so that the temperature of the solution was kept at 4°C, and then 400 microliters of pyrrole monomer (Py) was added to the dispersion, and then the ammonium persulfate solution was added dropwise to the dispersion; after the addition, the solution was kept The reaction temperature was carried out in an ice-water bath (4° C.) for 5 hours, and the obtained product was washed several times with deionized water and dried to obtain molybdenum oxide nanowires coated with polypyrrole;

[0070] 2) 160 mg of the obtained polypyr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com