Metal organic framework compound catalyst as well as preparation method and application thereof

A technology of metal-organic frameworks and compounds, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, catalytic reactions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In order to realize the above-mentioned technical purpose, the invention provides a kind of Cr based on metal organic framework compound, Fe, the preparation method of Al ternary homogeneous catalyst, this preparation method comprises the following steps:

[0061] Disperse a certain molar ratio of aluminum salt, chromium salt, iron salt and organic ligand in a solvent to form a mixed solution; wherein, the molar ratio of aluminum salt to chromium salt is 1:0.02, or 1:0.1, or 1:0.15 , or a certain ratio within the interval, the molar ratio range of aluminum salt to iron salt is 1:0.005, or 1:0.01, or 1:0.04, or 1:0.08, or a certain ratio within the interval, the total metal ions and The ratio range of the organic ligand is 1:3, or 1:1, or 3:1, or a certain ratio within the range. The molar ratio of the aluminum salt to the solvent is 0.0001:1, or 0.0002:1, or 0.0005:1, or 0.001:1, or a certain ratio within the range. The aluminum salt includes one or more combinations o...

Embodiment 2

[0072] This embodiment provides a method for preparing a metal-organic framework compound catalyst, which includes the following steps:

[0073] Preparation of metal organic framework compound catalyst:

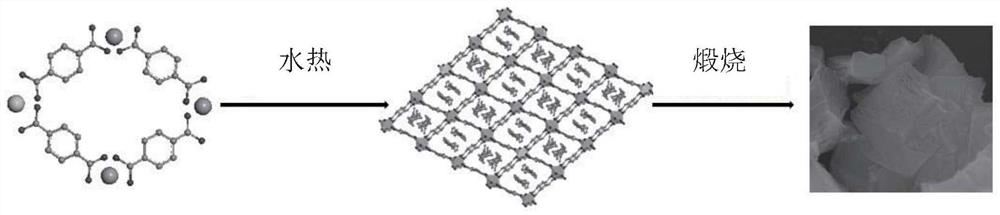

[0074] The schematic diagram of the synthesis of metal-organic framework compound catalysts is shown in figure 1 As shown, first, the three metal sources and organic ligands are dispersed in a solvent to form a mixed solution, which is then transferred to a reaction kettle for crystallization, and finally the metal-organic framework compound catalyst is obtained by roasting. details as follows:

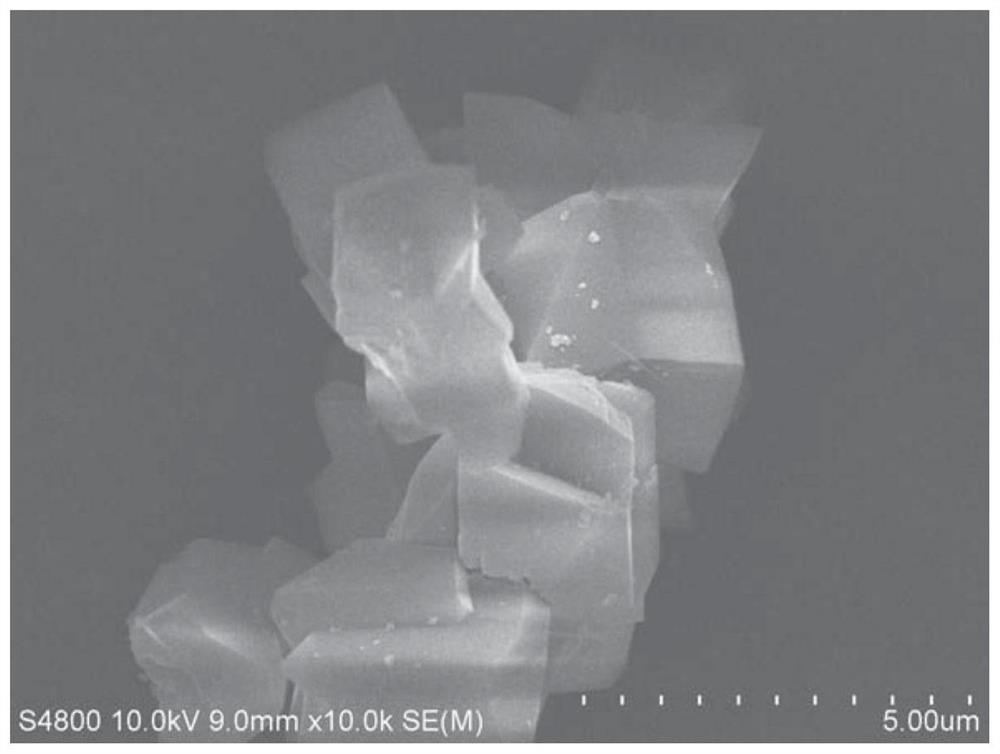

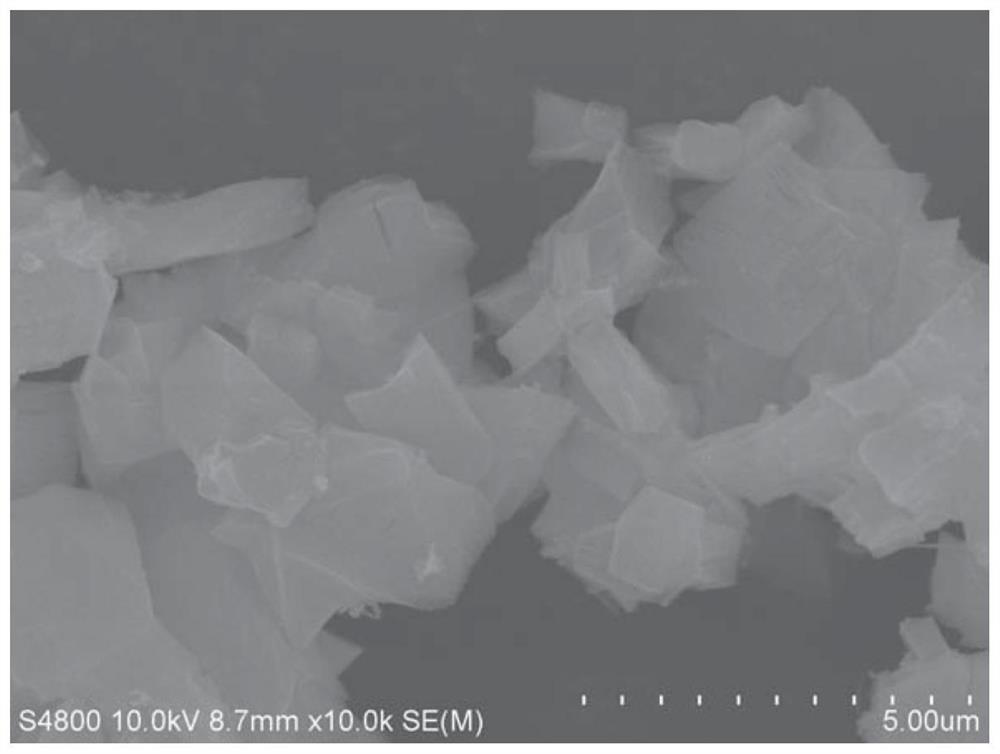

[0075] Disperse 8mmol aluminum nitrate nonahydrate, 0.4mmol chromium nitrate nonahydrate, 0.24mmol iron nitrate nonahydrate and 4mmol terephthalic acid in 50mL deionized water to form a mixed solution; stir evenly at room temperature and transfer to a 100mL reaction kettle for 180 ℃ crystallization for 24 hours, solid-liquid separation after cooling to obtain MOF (Al, Cr, Fe); in a...

Embodiment 3

[0082] The present embodiment provides the preparation method of the metal-organic framework compound derived CAT (Al, Cr) catalyst, which comprises the following steps:

[0083] Disperse 8mmol aluminum nitrate nonahydrate, 0.4mmol chromium nitrate nonahydrate and 4mmol terephthalic acid in 50mL deionized water to form a mixed solution; stir evenly at room temperature and transfer to a 100mL reactor for crystallization at 180°C for 24h, after cooling MOF (Al, Cr) was obtained by solid-liquid separation; in a static air atmosphere, the temperature of MOF (Al, Cr) was raised to 450 °C at a rate of 3 °C / min and kept at a constant temperature for 3 h to obtain CAT (Al , Cr) catalyst. Tested by the nitrogen physical low-temperature adsorption method, the catalyst has a double pore structure, the micropore size is 0.3-0.5nm, the mesopore size is 4-50nm, and the specific surface area calculated by the BET method is 180m 2 / g. The loading amount of chromium in the catalyst is 5% by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com