Heater for detecting temperature characteristic of optical filter

A technology of temperature characteristics and optical filters, which is applied in the direction of testing optical properties, heating elements, ohmic resistance heating parts, etc., can solve the problems of not having the heating function of test samples, etc., and achieves convenient replacement of optical filters and good heat conduction effect , to ensure the effect of heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

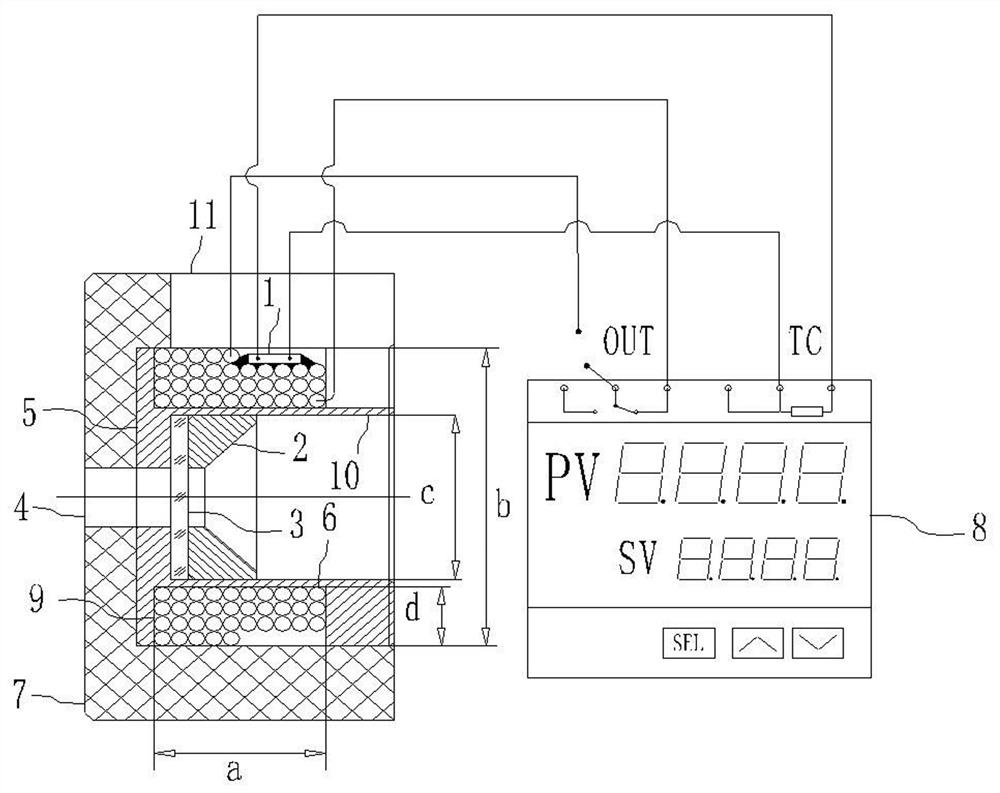

[0030] As shown in the figure, the measurement light of the spectrophotometer passes through the optical filter 3 through the light hole 4 to realize the measurement of the spectral characteristics. The temperature control meter 8 controls the heating of the heating wire according to the measured temperature, so that the optical filter 3 is heated.

[0031] Taking the detection of the temperature characteristics of the optical filter 3 of Φ11×1 mm as an example, the inner cavity of the heat-conducting inner core 5 can be made into a cylinder with a diameter of Φ11 mm to facilitate the placement of the optical filter 3 . The light hole at the bottom edge is Φ4mm, which is enough to meet the size of the measuring beam, and the contact area should be increased as much as possible. The enamelled heating wire 6 is an enamelled nickel-chromium wire with a diameter of 0.4 mm, the resistance per unit length is 8.54 ohm / m, and the maximum temperature resistance reaches 150 degrees, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com