Novel composite additive for tubular high-pressure polyethylene and preparation method of novel composite additive

A technology of high-pressure polyethylene and compound additives, applied in the field of polyethylene additives, can solve the problems of reducing the squatting rate, loss of production and processing enterprises, poor transparency, etc., and achieves the improvement of antioxidant performance, which is beneficial to environmental protection production and reduces the addition of additives. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

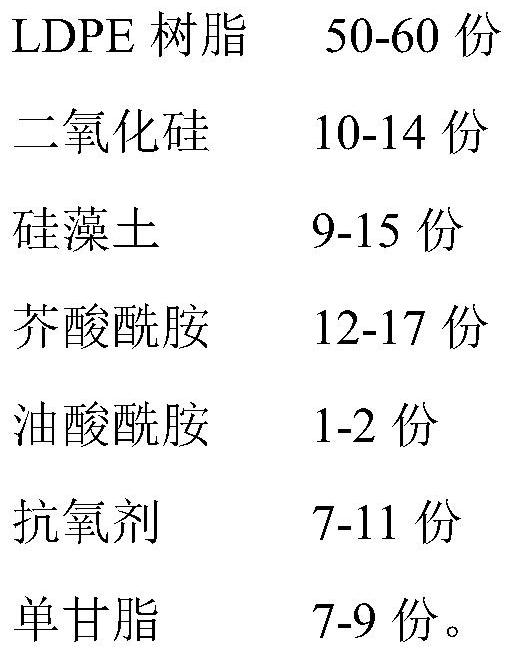

[0042] The new composite additive for tubular high-pressure polyethylene described in Example 1 consists of the following raw materials in parts by weight:

[0043]

[0044] in:

[0045] The LDPE resin is a mixture of LDPELD605 and LDPELD607; wherein the mass ratio of LDPELD605 to LDPELD607 is 1:1; the density of the LDPELD605 is 0.922g / cm 3 , the melt index is 6.0g / 10min, the tensile strength at break is 8MPa; the density of the LDPE607 is 0.921g / cm 3 , Melt index is 7.5g / 10min, tensile strength at break is 9MPa.

[0046] SiO in the described silicon dioxide powder 2 The content of > 99%.

[0047] The particle size of the diatomite D50 is 3.5um, and the density is 2.0g / cm 3 , the specific surface area is 40m 2 / g; in mass percentage, including the following chemical composition: SiO 2 94%, Fe 2 o 3 0.8%, Al 2 o 3 1.2% and CaO 0.6%.

[0048] The erucamide has a melting point of 80-83°C, an iodine value of 72-77gl2 / 100g, and an amide content of ≥98wt%.

[0049] T...

Embodiment 2

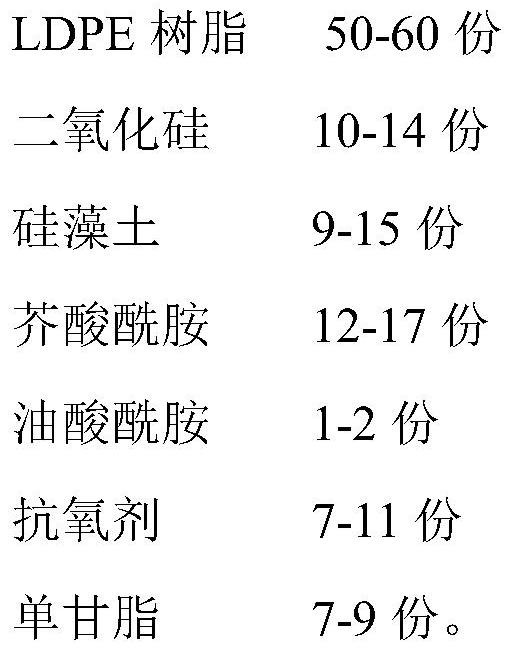

[0060] The new composite additive for tubular high-pressure polyethylene described in Example 2, in parts by weight, consists of the following raw materials:

[0061]

[0062]

[0063] in:

[0064] The LDPE resin is a mixture of LDPELD605 and LDPELD607; wherein the mass ratio of LDPELD605 to LDPELD607 is 1:1.2; the density of the LDPELD605 is 0.922g / cm 3 , the melt index is 6.0g / 10min, the tensile strength at break is 8MPa; the density of the LDPE607 is 0.921g / cm 3 , Melt index is 7.5g / 10min, tensile strength at break is 9MPa.

[0065] SiO in the described silicon dioxide powder 2 The content of > 99%.

[0066] The particle size of the diatomite D50 is 3.5um, and the density is 2.0g / cm 3 , the specific surface area is 40m 2 / g; in mass percentage, including the following chemical composition: SiO 2 94%, Fe 2 o 3 0.8%, Al 2 o 3 1.2% and CaO 0.6%.

[0067] The erucamide has a melting point of 80-83°C, an iodine value of 72-77gl2 / 100g, and an amide content of ≥98...

Embodiment 3

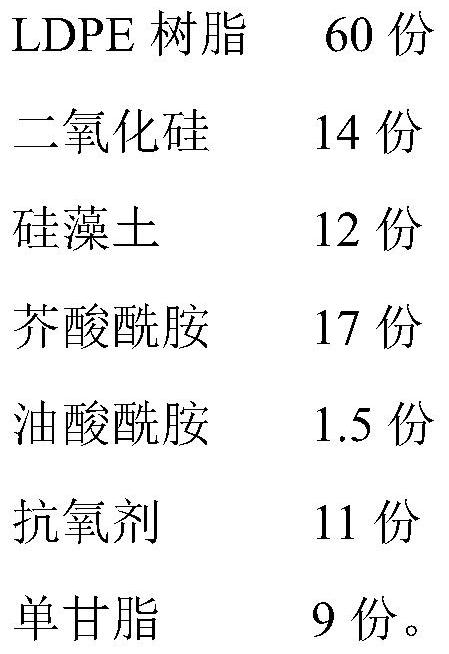

[0079] The new composite additive for tubular high-pressure polyethylene described in Example 3, in parts by weight, consists of the following raw materials:

[0080]

[0081] in:

[0082] The LDPE resin is a mixture of LDPELD605 and LDPELD607; wherein the mass ratio of LDPELD605 to LDPELD607 is 1:1.5; the density of the LDPELD605 is 0.922g / cm 3 , the melt index is 6.0g / 10min, the tensile strength at break is 8MPa; the density of the LDPE607 is 0.921g / cm 3 , Melt index is 7.5g / 10min, tensile strength at break is 9MPa.

[0083] SiO in the described silicon dioxide powder 2 The content of > 99%.

[0084] The particle size of the diatomite D50 is 3.5um, and the density is 2.0g / cm 3 , the specific surface area is 40m 2 / g; in mass percentage, including the following chemical composition: SiO 2 94%, Fe 2 o 3 0.8%, Al 2 o 3 1.2% and CaO 0.6%.

[0085] The erucamide has a melting point of 80-83°C, an iodine value of 72-77gl2 / 100g, and an amide content of ≥98wt%.

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com