High-low-temperature anti-fog gas-permeable polyolefin heat-sealing film for fruit and vegetable packaging, and preparation method thereof

A high-low temperature, heat-sealing film technology, used in packaging, wrapping paper, biological packaging, etc., can solve the problems of increasing the air permeability of the film, reducing the heat-sealing strength of the film, and reducing the strength of the film, etc. It is beneficial to market development, The film strength is not reduced and the preparation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

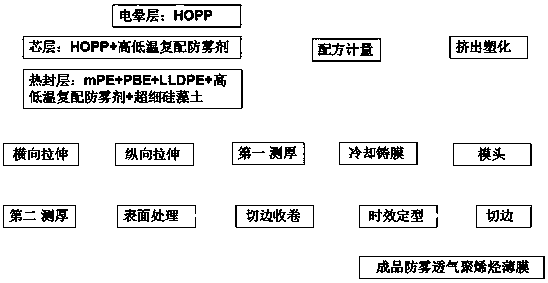

[0063] A high and low temperature anti-fog and breathable polyolefin heat-sealing film for fruit and vegetable packaging, including a corona layer, a core layer and a heat-sealing layer from top to bottom; the layer ratio structure of its three-layer co-extrusion is: corona layer / core Layer / heat seal layer: HOPP / (HOPP+high and low temperature antifogging agent) / (mPE+LLDPE+PBE+high and low temperature antifogging agent+ultrafine diatomaceous earth), corona layer 30wt%, core layer 50wt%, heat sealing layer 20wt%.

[0064] In this embodiment, the heat-sealing layer is a multi-component composite system composed of mPE, PBE elastomer, LLDPE, ultrafine diatomaceous earth, and high and low temperature compound antifogging agent.

[0065] In this example, the formula ratio of the heat-sealing layer is: 0.5wt% of high-temperature antifogging agent, 1wt% of low-temperature antifogging agent, 40wt% of PBE elastomer, 5wt% of LLDPE, 50wt% of mPE, and 3.5wt% of ultrafine diatomaceous earth...

Embodiment 2

[0079] A high and low temperature anti-fog and breathable polyolefin heat-sealing film for fruit and vegetable packaging, including a corona layer, a core layer and a heat-sealing layer from top to bottom; the layer ratio structure of its three-layer co-extrusion is: corona layer / core Layer / heat seal layer: HOPP / (HOPP+high and low temperature antifogging agent) / (mPE+LLDPE+PBE+high and low temperature antifogging agent+ultrafine diatomaceous earth), corona layer 25wt%, core layer 55wt%, heat sealing layer 20wt%.

[0080] In this embodiment, the heat-sealing layer is a multi-component composite system composed of mPE, PBE elastomer, LLDPE, ultrafine diatomaceous earth, and high and low temperature compound antifogging agent.

[0081] In this example, the formula ratio of the heat-sealing layer is: high-temperature antifogging agent 1wt%, low-temperature antifogging agent 1.5wt%, PBE elastomer 45wt%, LLDPE 8wt%, mPE 40.5wt%, ultrafine diatomaceous earth 4wt%.

[0082] In this em...

Embodiment 3

[0095] A high-low temperature anti-fog and breathable polyolefin heat-sealing film for fruit and vegetable packaging, including a corona layer, a core layer and a heat-sealing layer from top to bottom; the layer ratio structure of the three-layer co-extrusion is: corona layer / core Layer / heat seal layer: HOPP / (HOPP+high and low temperature antifogging agent) / (mPE+LLDPE+PBE+high and low temperature antifogging agent+ultrafine diatomaceous earth), corona layer 20wt%, core layer 60wt%, heat sealing layer 20wt%.

[0096] In this embodiment, the heat-sealing layer is a multi-component composite system composed of mPE, PBE elastomer, LLDPE, ultrafine diatomaceous earth, and high and low temperature compound antifogging agent.

[0097] In this example, the formula ratio of the heat seal layer is: high temperature antifogging agent 2wt%, low temperature antifogging agent 2.5wt%, PBE elastomer 30wt%, LLDPE10wt%, mPE50.5wt%, ultrafine diatomaceous earth 5.0wt% .

[0098] In this embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com