Pd-doped rGO/ZnO-SnO2 heterojunction quaternary composite material as well as preparation method and application thereof

A composite material and heterojunction technology, applied in separation methods, analytical materials, material resistance, etc., can solve problems such as poor selectivity, long response/recovery time parameters, small gas response, etc., to improve performance, enrich surface defects, The effect of lowering the response temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

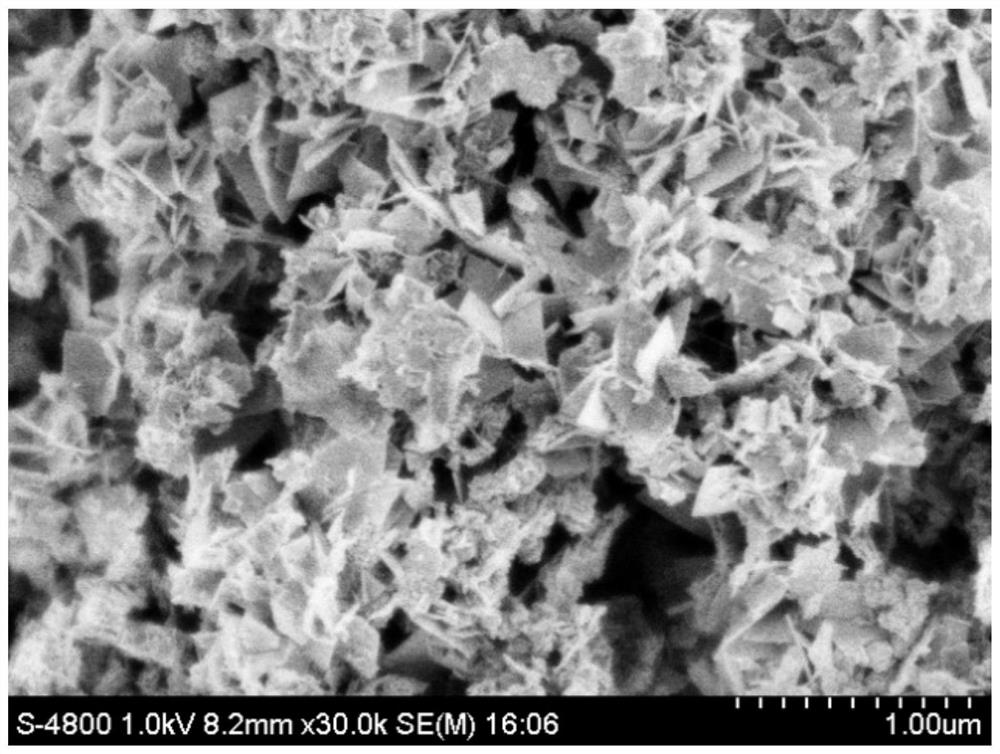

[0048] (1) Dissolve zinc acetate dihydrate and sodium hydroxide in deionized water at a molar ratio of 1:2, and stir them magnetically for 1 hour after mixing; After the reaction, the autoclave was naturally cooled to room temperature; the precipitate was collected after centrifugation, washed alternately with deionized water and ethanol three times, dried at 60°C for 12 hours, and placed in a muffler after drying. In the furnace, the temperature was raised to 500° C. for 2 hours at a rate of 3° C. / min and calcined for 2 hours to obtain flake ZnO nanomaterials.

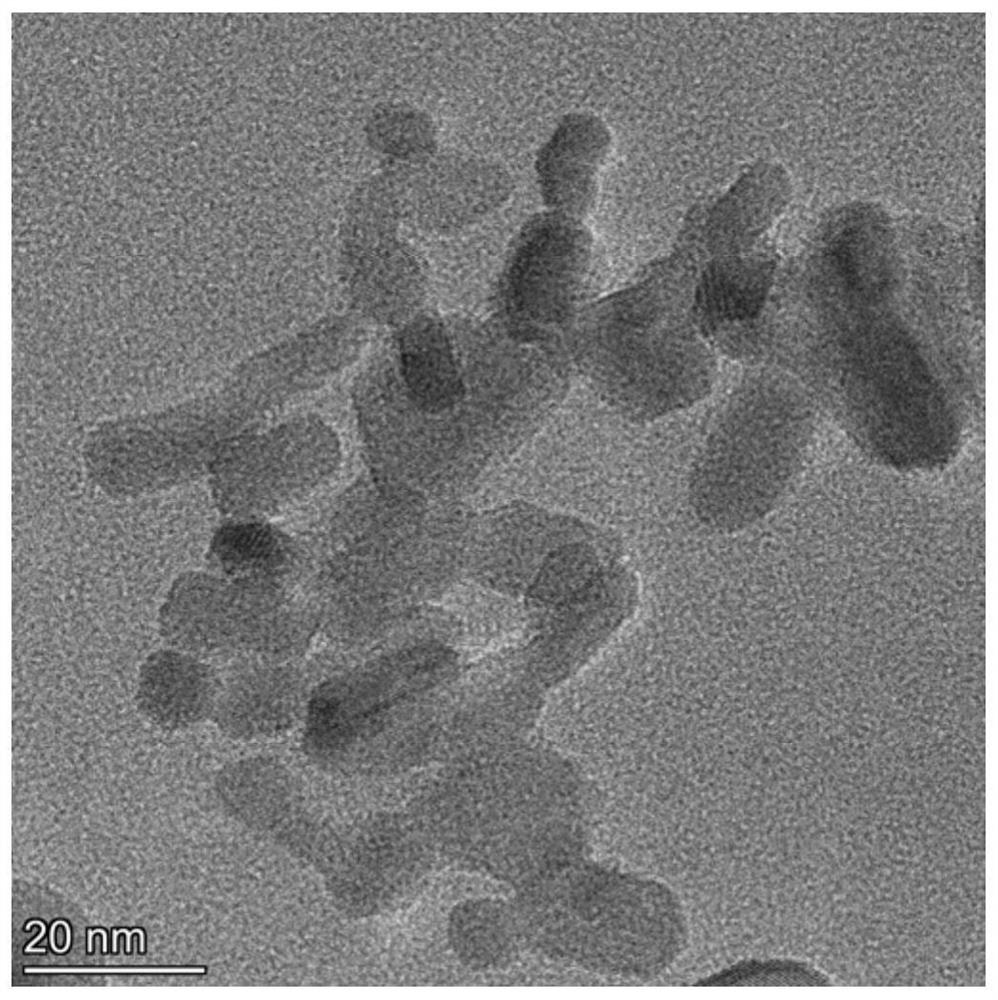

[0049] (2) Add the flaky ZnO nanomaterial and tin protochloride tetrahydrate into deionized water, after magnetic stirring and mixing, first add DMF, then dropwise add sodium hydroxide solution, then add palladium chloride, magnetic stirring and mixing After being uniform, mixed solution is obtained; Wherein, the mol ratio of flaky ZnO nanometer material, stannous chloride tetrahydrate and sodium hydroxide is 1:2:5; V...

Embodiment 2

[0061] (1) Dissolve zinc acetate dihydrate and sodium hydroxide in deionized water at a molar ratio of 1:4, and stir them magnetically for 1 hour after mixing; After the reaction, the autoclave was naturally cooled to room temperature; the precipitate was collected after centrifugation, washed alternately with deionized water and ethanol three times, dried at 60°C for 12 hours, and placed in a muffler after drying. In the furnace, the temperature was raised to 500°C at a rate of 4°C / min and calcined for 2 hours to obtain sheet ZnO nanomaterials.

[0062] (2) Add the flaky ZnO nanomaterial and tin protochloride tetrahydrate into deionized water, after magnetic stirring and mixing, first add DMF, then dropwise add sodium hydroxide solution, then add palladium chloride, magnetic stirring and mixing After being uniform, mixed solution is obtained; Wherein, the mol ratio of flaky ZnO nanometer material, stannous chloride tetrahydrate and sodium hydroxide is 1:4:8; V DMF :n ZnO =1...

Embodiment 3

[0071] Graphene oxide powder is ZnO and SnO in step (1) in the present embodiment 2 1.5% of the total mass, all the other are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com