Material for synchronously removing ammonia nitrogen and phosphorus and preparation method thereof

A technology for removing ammonia and ammonia nitrogen, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of strong environmental dependence, long cycle, and cumbersome biological denitrification and phosphorus removal process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

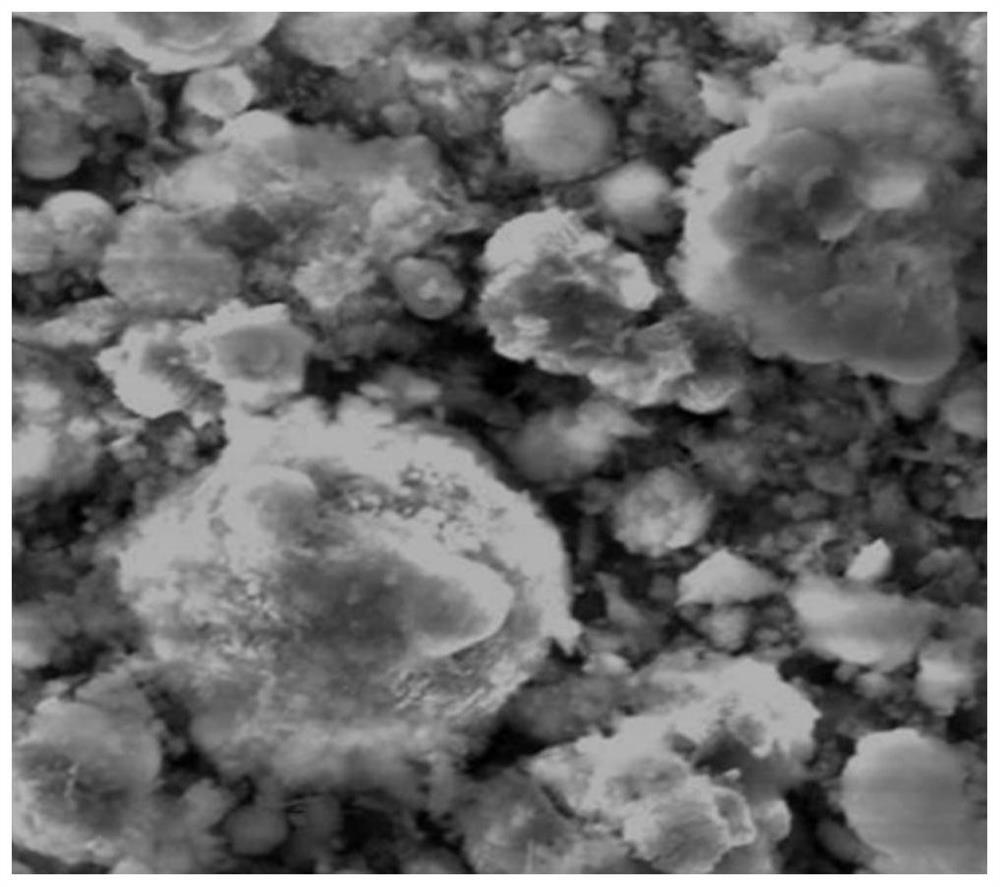

Image

Examples

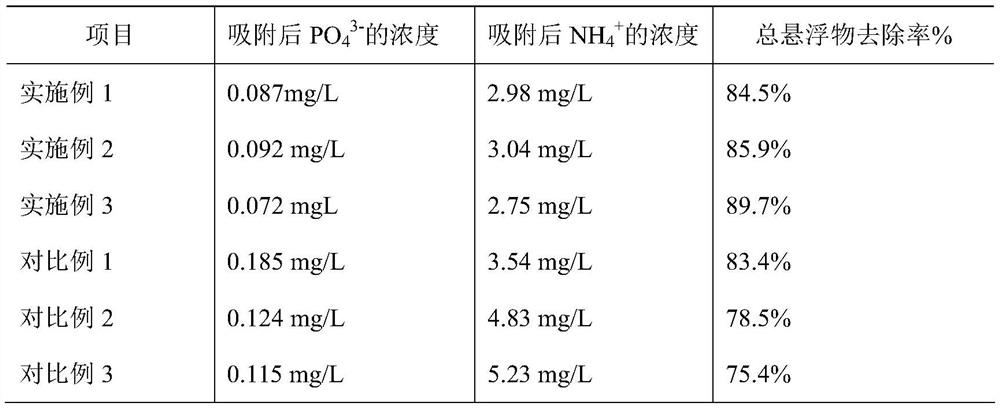

Embodiment 1

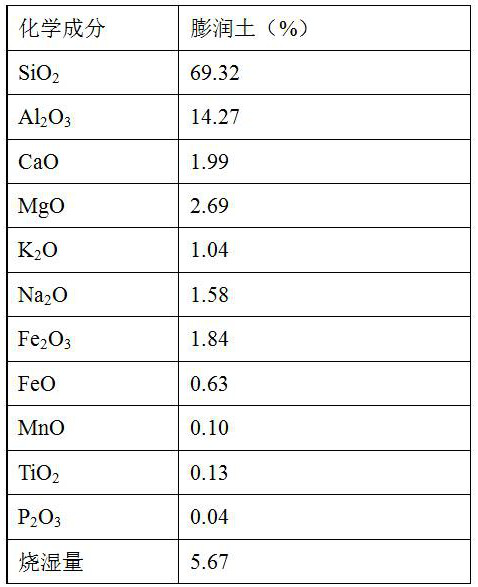

[0026] A material for simultaneous removal of ammonia nitrogen and phosphorus, including the following raw materials: 10kg of kaolin, 1kg of bentonite, 10kg of soda ash, 60kg of water, 8kg of zirconium oxychloride, and 5kg of lanthanum cerium chloride.

[0027] The preparation method of the above-mentioned material for synchronous removal of ammonia nitrogen and phosphorus comprises the following steps:

[0028] (1) Mix kaolin, bentonite, soda ash and 40kg water;

[0029] (2) Zirconium oxychloride, lanthanum cerium chloride, and the remaining water are added to form a solution, and added to step (1) for 3 hours, and stirred;

[0030] (3) Heat up to 150°C; stir for 20 hours, press filter, dry and pulverize to obtain the finished product.

Embodiment 2

[0032] A material for simultaneous removal of ammonia nitrogen and phosphorus, including the following raw materials: 6kg of kaolin, 4kg of bentonite, 20kg of soda ash, 100kg of water, 3kg of zirconium oxychloride, and 9kg of lanthanum cerium chloride.

[0033] The preparation method of the above-mentioned material for synchronous removal of ammonia nitrogen and phosphorus comprises the following steps:

[0034] (1) Mix kaolin, bentonite, soda ash and 60kg water;

[0035] (2) Zirconium oxychloride, lanthanum cerium chloride, and the remaining water are added to form a solution, and added to step (1) for 1.5 hours, and stirred;

[0036] (3) Heat up to 200°C; stir for 15 hours, press filter, dry and pulverize to obtain the finished product.

Embodiment 3

[0038] A material for simultaneous removal of ammonia nitrogen and phosphorus, including the following raw materials: 8kg of kaolin, 2kg of bentonite, 15kg of soda ash, 80kg of water, 5kg of zirconium oxychloride, and 7kg of lanthanum cerium chloride.

[0039] The preparation method of the above-mentioned material for synchronous removal of ammonia nitrogen and phosphorus comprises the following steps:

[0040] (1) Mix kaolin, bentonite, soda ash and 60kg water;

[0041] (2) Zirconium oxychloride, lanthanum cerium chloride, and the remaining water are added to form a solution, and added to step (1) for 2 hours, and stirred;

[0042] (3) Heat up to 180°C; stir for 18 hours, press filter, dry and pulverize to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com