Textile fabric setting process

A technology of textile fabrics and processes, applied in the field of clothing fabrics, can solve the problems of easy occurrence of creases, poor stretch recovery, and easy agglomeration into agglomerates, so as to improve anti-wrinkle performance, reduce stretch recovery, and reduce fluff or hair loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

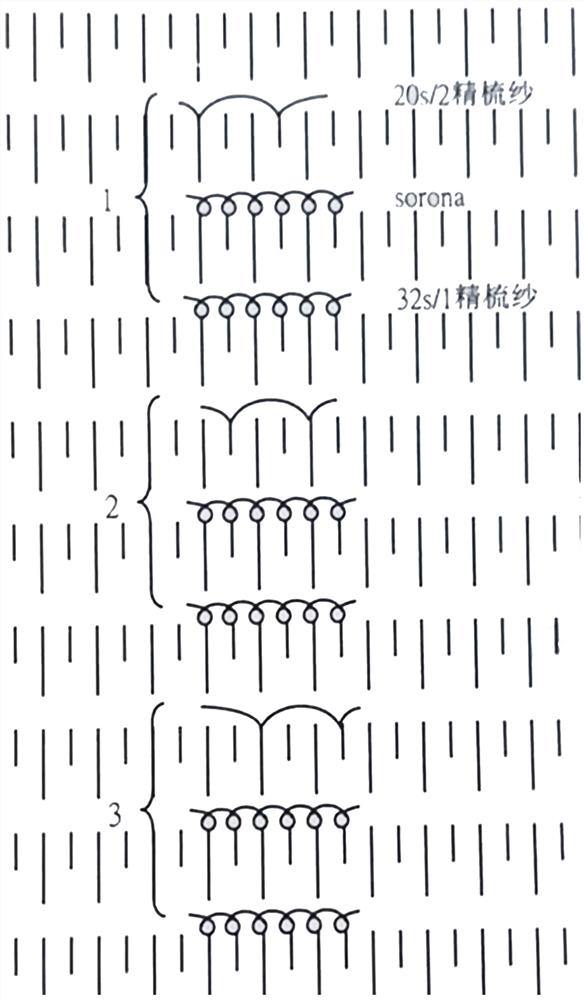

Image

Examples

Embodiment 1

[0043] A shaping process for textile fabrics, comprising the following steps:

[0044] S1, weaving: using combed cotton yarn and sorona cotton yarn as raw materials, according to the sandwich weaving method, weaving into gray cloth; adopting the combed cotton yarn with a cotton length of 18mm as the base yarn, adopting the sorona cotton yarn with a cotton length of 28mm as the middle yarn, using The combed cotton yarn with a cotton length of 38mm is the veil.

[0045] S2. Embossing: put the gray cloth into the setting machine for embryo setting; the gray cloth is first passed through 75°C hot water, and then shaped in the setting machine at a temperature of 200°C and a speed of 15m / min.

[0046] S3. Front singeing: Put the gray cloth after the embryo determination into the singeing machine, perform singeing treatment on the front side of the singeed gray cloth, and remove the fluff on the front side of the gray cloth; the burner temperature of the singeing machine is 1100°C, t...

Embodiment 2

[0055] A shaping process for textile fabrics, comprising the following steps:

[0056] S1, weaving: using combed cotton yarn and sorona cotton yarn as raw materials, weaving gray cloth according to the sandwich weaving method; adopting the combed cotton yarn with a cotton length of 22mm as the base yarn, adopting the sorona cotton yarn with a cotton length of 32mm as the middle yarn, using The combed cotton yarn with a cotton length of 43mm is the veil.

[0057] S2. Embryo setting: Put the gray cloth into the shaping machine for embryo setting; the gray cloth is first passed through 90°C hot water, and then shaped in the setting machine at a temperature of 230°C and a speed of 20m / min.

[0058] S3. Front singeing: put the gray cloth after the embryo setting into the singeing machine, perform singeing treatment on the front side of the singeed gray cloth, and remove the fluff on the front side of the gray cloth; the burner temperature of the singeing machine is 1400°C, the spee...

Embodiment 3

[0067] A shaping process for textile fabrics, comprising the following steps:

[0068] S1, weaving: using combed cotton yarn and sorona cotton yarn as raw materials, weaving gray cloth according to the sandwich weaving method; using combed cotton yarn with a cotton length of 20mm as the base yarn, adopting a cotton length of 30mm sorona cotton yarn as the middle yarn, using The combed cotton yarn with a cotton length of 40mm is the veil.

[0069] S2. Embryo setting: put the gray cloth into the setting machine for embryo setting; the gray cloth is first passed through 80°C hot water, and then shaped in the setting machine at a temperature of 210°C and a speed of 18m / min.

[0070] S3. Front singeing: Put the gray cloth after the embryo determination into the singeing machine, perform singeing treatment on the front side of the singeed gray cloth, and remove the fluff on the front side of the gray cloth; the burner temperature of the singeing machine is 1300°C, the speed It is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com