Polyester long-fiber FDY (fully drawn yarn) oil solution

A technology of polyester long fiber and oil agent, which is applied in fiber treatment, fiber type, textiles and papermaking, etc. It can solve the problems of poor slurry compatibility, poor smoothness, and high cost, and achieve reduced cleaning times, Improved spinning quality and high electrical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of polyester long fiber FDY oil agent, based on the total weight of the polyester long fiber FDY oil agent, it is mixed by the following components in percentage:

[0040] POE (5) Stearyl Ether, 14%; POE (5) Potassium Lauryl Ether Phosphate, 7%; POE (30) Castor Oil, 4%; PEG (400) Laurosilicate Diester, 6%; Sodium Lauryl Sulfonate, 6%; Atactic Polyether, 13%; POE (7) Benzyl Phenylphenol Ether, 9.5%-10.5%; Dioctyl Sebacate, 10%; Trimethylol Propane Dicaprate, 22%; Cetyl Alcohol, 5%; Butyl Cellosolve, 3%.

Embodiment 2

[0042] A kind of polyester long fiber FDY oil agent, based on the total weight of the polyester long fiber FDY oil agent, it is mixed by the following components in percentage:

[0043] POE (5) Stearyl Ether, 13%; POE (5) Potassium Lauryl Ether Phosphate, 6%; POE (30) Castor Oil, 6%; PEG (400) Laurosilicate Diester, 7%; Sodium Lauryl Sulfonate, 5%; Atactic Polyether, 14%; POE (7) Benzyl Phenyl Phenol Ether, 9%; Dioctyl Sebacate, 9%; Cetyl Alcohol, 23%; Cetyl Alcohol, 5%; Butyl Cellosolve, 3%.

Embodiment 3

[0045] A kind of polyester long fiber FDY oil agent, based on the total weight of the polyester long fiber FDY oil agent, it is mixed by the following components in percentage:

[0046] POE (5) Stearyl Ether, 12%; POE (5) Potassium Lauryl Ether Phosphate, 8%; POE (30) Castor Oil, 7%; PEG (400) Laurosilicate Diester, 4%; Sodium Lauryl Sulfonate, 4%; Atactic Polyether, 15%; POE (7) Benzyl Phenylphenol Ether, 8%; Dicapryl Sebacate, 8%; Cetyl Alcohol, 25%; Cetyl Alcohol, 5%; Butyl Cellosolve, 4%.

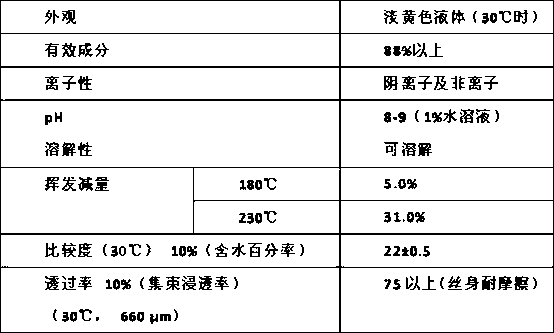

[0047] The basic characteristics of the FDY oil agent provided by the embodiment of the present invention 1 are as follows:

[0048]

[0049] Polyester long fiber FDY oil is compounded based on the optimum cloud point of the oil. The cloud point of the oil provided in Example 1 is 60°C±1°C; the cloud point of the oil provided in Example 2 is 55°C. °C ± 1 °C; the cloud point of the oil provided in Example 3 is 65 °C ± 1 °C. In comparison, the oil quality provided by Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com