Yarn guiding plate, yarn receiving device, and work position operation method

A technology of yarn guide plate and station, which is applied in the direction of transportation and packaging, delivery of filamentous materials, and thin material processing, etc., and can solve the problems of damage and instability of the components of the yarn splicing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

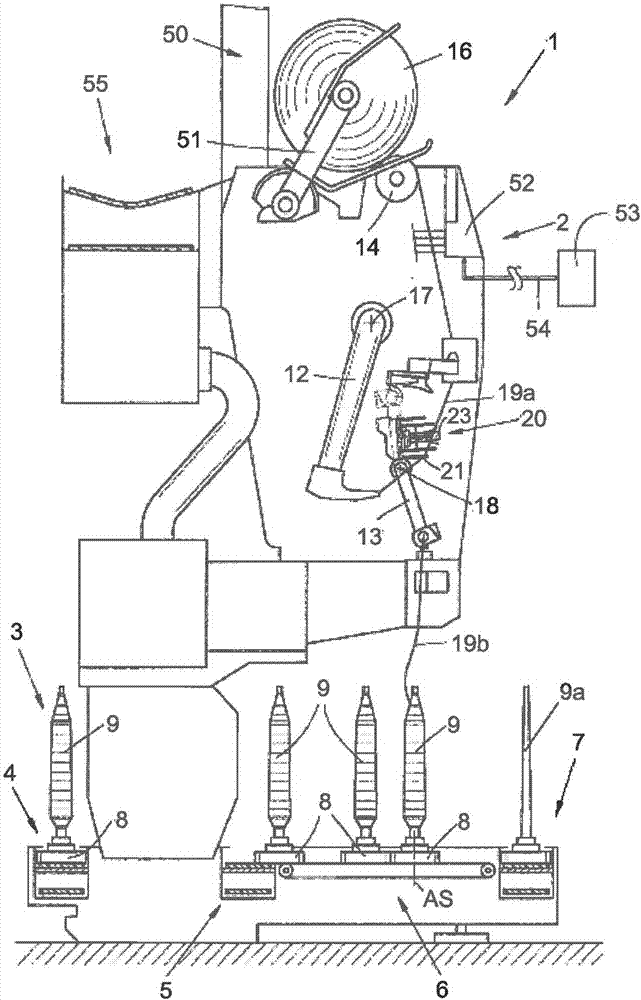

[0038] figure 1 A schematic side view of a station 2 of a winder 1 in the form of an automatic cross-winder winder is shown according to one embodiment.

[0039] As is known, such an automatic cross-winding winder 1 has a plurality of identical stations 2 , here winding positions 2 , between its (not shown) end frames. In the winding position 2, the bobbin 9 used as an unwinding bobbin is rewound into a large package crosswinding bobbin 16 as a winding bobbin.

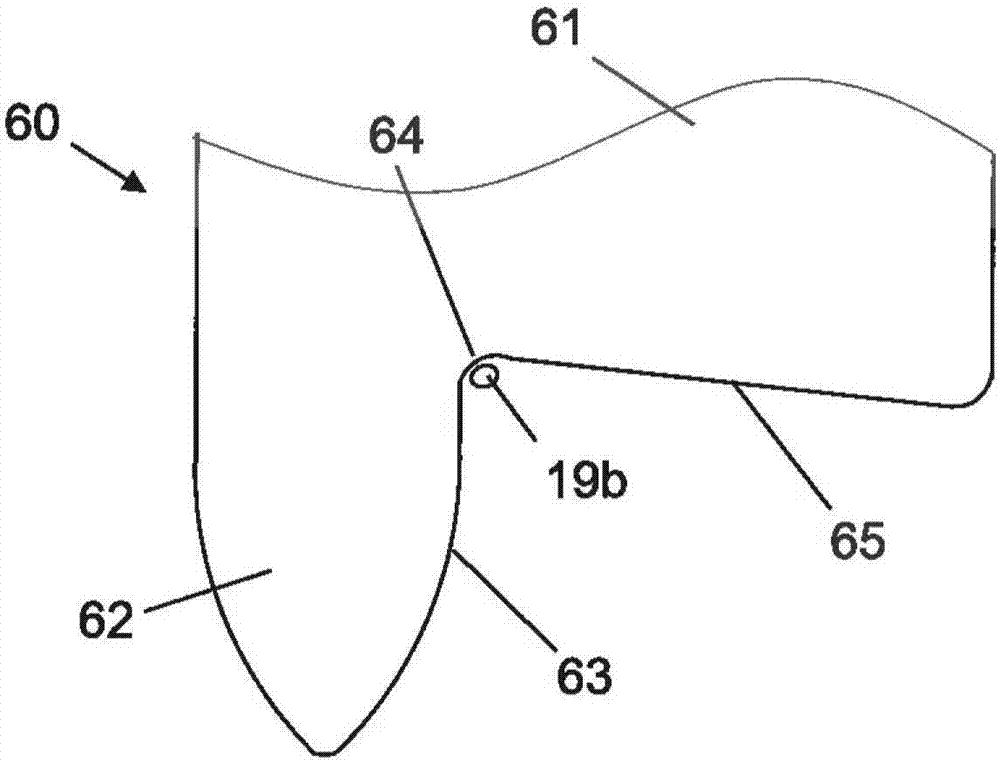

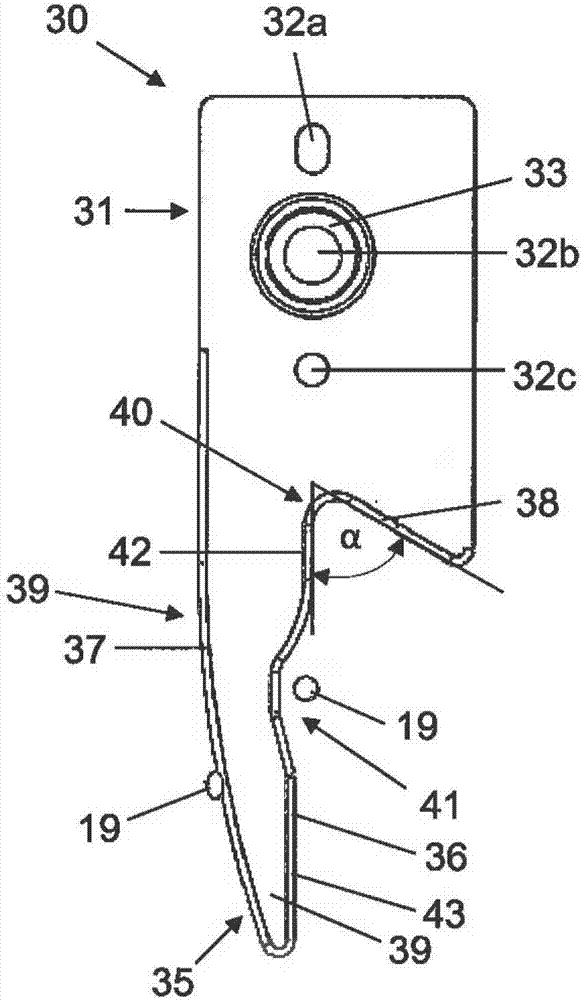

[0040] The winding position 2 has a yarn splicing device 10 slightly retracted from the normal yarn path for joining the so-called top yarn 19 a from the cross-wound bobbin 16 with the so-called bottom yarn 19 b from the bobbin 9 . Such a yarn connection may be required, for example, when a new bobbin 9 is provided, when the yarn is split, or in a controlled so-called clearing step for removing yarn defects.

[0041] The basic mode of operation of such an automatic cross-winding winder 1 is previously disclosed, for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com