Polypyrrole/graphene/epoxy resin super-slippage coating suitable for photo-thermal deicing and preparation method thereof

An epoxy resin, polypyrrole technology, applied in epoxy resin coatings, coatings, etc., can solve the problem of losing water sliding properties, hindering coating application and handling, super-slip surface anti-icing, photothermal deicing is not very good. Ideal and other problems, to achieve the effect of enhancing compactness and mechanical strength, stability, good stability and anti-icing performance, and improving photothermal deicing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

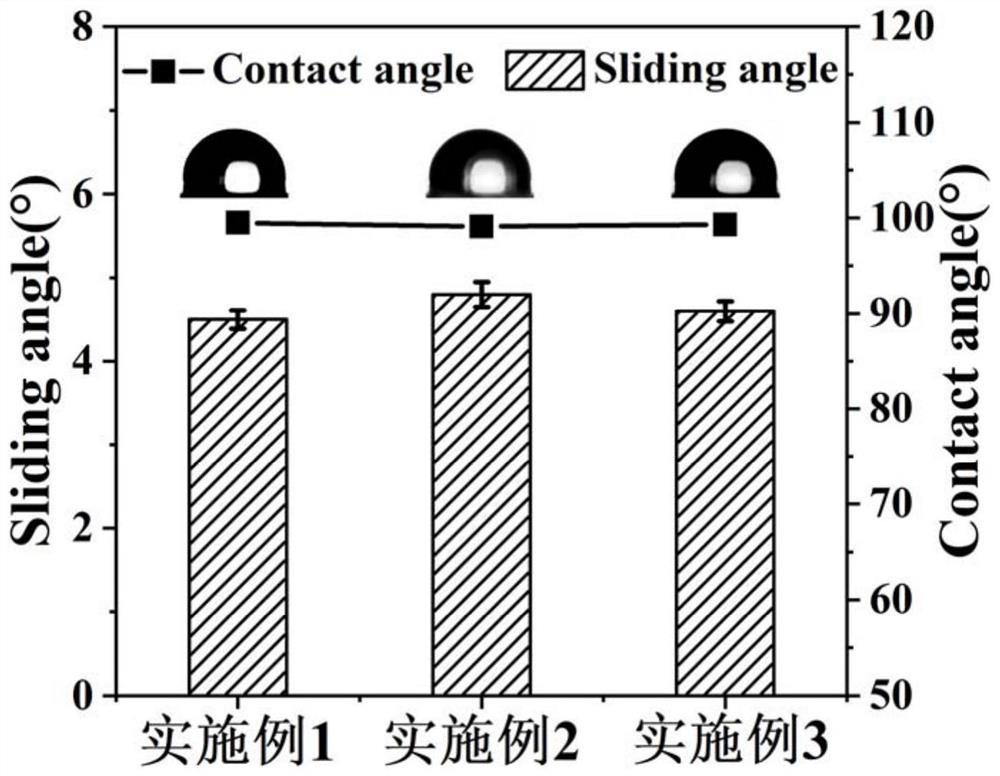

Embodiment 1

[0032] Pre-treatment of the substrate: the substrate of the sample is a sailboat brand glass slide, which is sprayed immediately after wiping with absolute ethanol;

[0033] Step 1. Prepare component A:

[0034] Add 5g of DY-E44 type epoxy resin and 50ml of absolute ethanol to a 200ml beaker, disperse for 40min at a speed of 1500r / min on a magnetic stirrer, then add 0.2g of monoglycidyl ether-capped polydimethylsiloxane , 0.28g of diglycidyl ether-capped polydimethylsiloxane and 0.2g of graphene / polydopamine powder were ultrasonically dispersed for 25 minutes to prepare coating component A;

[0035] Among them, the preparation method of graphene / polydopamine powder is: add 0.2g graphene powder and 100mL Tris buffer to a 250mL beaker for ultrasonic dispersion for 30min, then add 0.2g dopamine hydrochloride and stir for 18-24h, centrifuge and purify at 60°C Graphene / polydopamine powder can be obtained by drying under the oven for 4 hours;

[0036] Step 2. Preparation of compon...

Embodiment 2

[0042] Adopt the mode as described in embodiment 1, substrate is processed, the preparation of B component in step 2 and the preparation of graphene / polydopamine powder in step 3;

[0043] Step 1. Prepare component A:

[0044] Add 5.8g of DY-E44 type epoxy resin and 50ml of absolute ethanol to a 200ml beaker, disperse on a magnetic stirrer at a speed of 1500r / min for 45min, then add 0.2g of monoglycidyl ether-capped polydimethylsiloxane Alkane, 0.28g diglycidyl ether-terminated polydimethylsiloxane, 0.1g amino-terminated polydimethylsiloxane and 0.2g graphene / polydopamine powder, ultrasonically dispersed for 20min to prepare coating group A Minute;

[0045] Step 3, prepare polypyrrole / graphene / epoxy resin super-slip coating:

[0046] First, mix component A and component B according to the mass ratio of 1:0.8, and disperse the mixture on a magnetic stirrer at a speed of 2000r / min for 55min; Spraying; finally, the coatings sprayed with components A and B are cured at 120°C fo...

Embodiment 3

[0048] Adopt the mode described in embodiment 1, substrate is processed, the preparation of A component and the preparation of graphene / polydopamine powder in step 1, and the preparation of polypyrrole / polydopamine powder in step 2;

[0049] Step 2. Preparation of component B:

[0050] Add 4g of DY-E6012 type curing agent and 50ml of absolute ethanol into a 100ml beaker, disperse on a magnetic stirrer at a speed of 1200r / min for 40min, then add 0.2g of polypyrrole / polydopamine powder, and ultrasonically disperse for 30min to obtain a coating Layer B component;

[0051] Step 3, prepare polypyrrole / graphene / epoxy resin super-slip coating:

[0052] First, mix component A and component B according to the mass ratio of 1:1, and disperse the mixture on a magnetic stirrer at a speed of 2000r / min for 60 minutes; then put the mixture into the spraying equipment and spray at a pressure of 1800Psi ; Finally, the coating sprayed with component A and component B is cured at 120°C for two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com