Efficient preparation method and application of aerogel material

An airgel, high-efficiency technology, applied in applications, chemical instruments and methods, household appliances, etc., can solve the problem of affecting the modification effect and use efficiency of surface modifiers in the later stage, affecting the quality of airgel and direct production costs, and environmental governance High cost and other problems, to achieve the effect of high efficiency and rapid ethanol removal efficiency, low environmental treatment cost, simple and effective process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

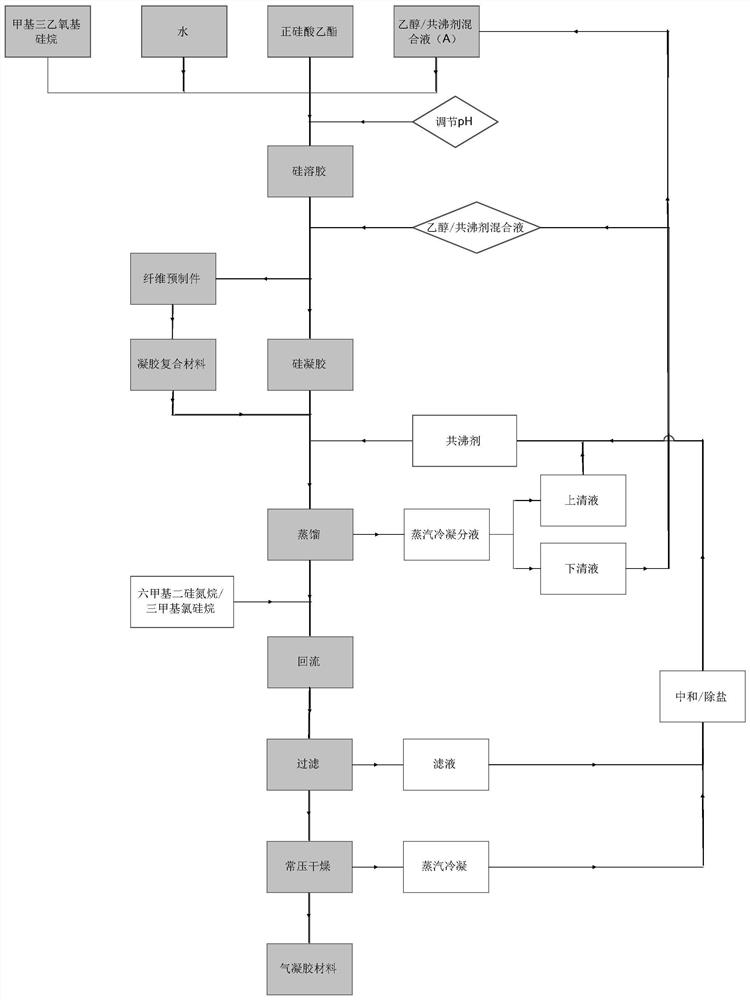

[0071] The efficient preparation method of the airgel material of the present invention, the preparation process is as follows figure 1 As shown, it specifically includes the following steps:

[0072] (1) Silica sol preparation: mix ethyl orthosilicate, methyltriethoxysilane, ethanol and entrainer mixture, and water according to the volume ratio of 1:0.1-0.5:5-25:0.1-0.3, adjust The pH is 4-5, after stirring for more than 2 hours, a silica sol is obtained.

[0073] (2) Preparation of silica gel: Dilute the silica sol described in step (1) to the target concentration with the mixture of ethanol and entrainer, adjust the pH to 7.5-8.5, stir quickly and evenly, and after standing still, the gel can be obtained . The gel composite is obtained by impregnating the fiber preform before gelling.

[0074] (3) Azeotropic distillation replacement: transfer the gel or gel composite material described in step (2) to a still, add an azeotropic agent to soak and heat to distill.

[0075]...

specific Embodiment 1

[0085] A method for preparing an airgel material. Mix 100mL tetraethyl orthosilicate, 30mL methyltriethoxysilane, 500mL ethanol, and 20mL water, adjust the pH to 4.5 with dilute hydrochloric acid, and stir for 2 hours to obtain a silica sol. Dilute the silica sol in equal volumes with a mixture of ethanol and an entrainer. The specific volume ratio of ethanol and entrainer is 1:0.1. Adjust the pH to 8.0 with dilute ammonia water. Stir quickly and evenly. After standing still, a gel can be obtained. Then the gel is simply crushed, transferred to a still, and hexamethyldisiloxane is added to submerge the gel particles, and the temperature of the heating medium is kept at 80°C for distillation, during which the hexamethyldisiloxane is continuously refluxed to maintain the liquid level Above the particles, until no 68-73°C distillate flows out, the replacement is completed. Then, add hexamethyldisilazane, a modifying agent with 5% volume of the gel material, into the distillation ...

Embodiment 2

[0088] A method for preparing an airgel material is similar to Example 1, except that trimethylchlorosilane is selected as the surface modifier. The obtained airgel is measured by Micromeritics Tristar 3020. The specific surface area of the airgel material is 692.5345 m² / g, the average BJH pore diameter is 11.2422 nm, and the particle density is 0.1530g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com