Tool and method for rapidly clamping and positioning special-shaped thin-wall extrusion part

A part and thin-walled technology, applied in the field of rapid clamping and positioning of special-shaped thin-walled extrusion parts, can solve the problems of low machining efficiency, affecting product manufacturing efficiency and cost, and low production cost, and improve machining accuracy and stability. , the support method is flexible and controllable, and the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

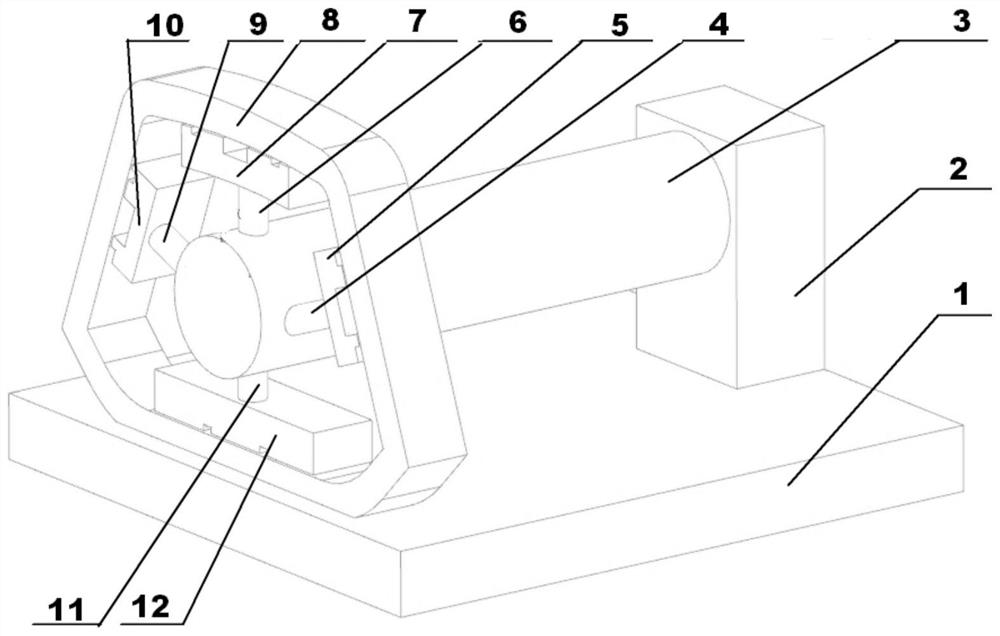

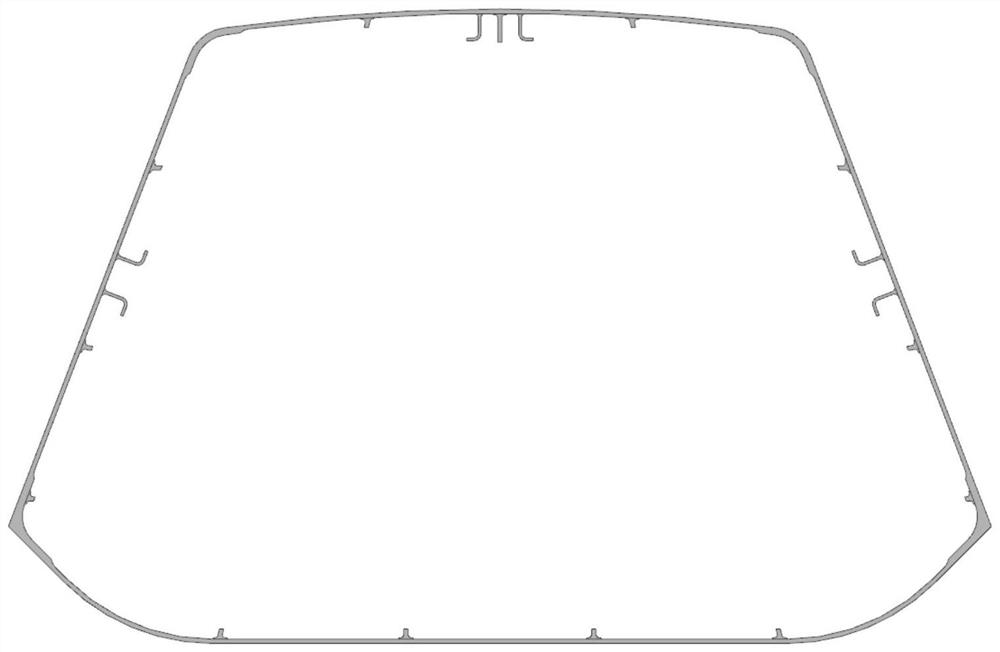

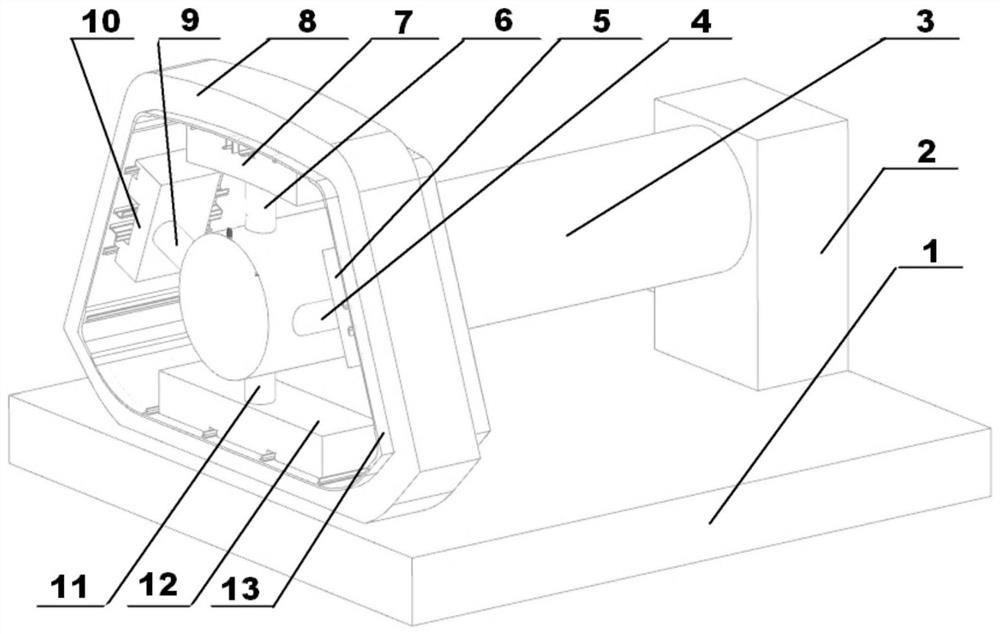

[0037] figure 1 It is a structural schematic diagram of a tooling for fast clamping and positioning of special-shaped thin-walled extruded parts according to the present invention. Outer frame 8, telescopic arm and follow-the-shaped briquetting block, telescopic arm is a hydraulic telescopic arm, and telescopic arm and follow-the-shaped briquetting block are 4, are respectively the first hydraulic telescopic arm 4, the second hydraulic telescopic arm 6, the third hydraulic telescopic arm The hydraulic telescopic arm 9 and the fourth hydraulic telescopic arm 11, and the first conformal briquetting block 5, the second conformal briquetting block 7, the third conformal briquetting block 10, and the fourth conformal briquetting block 12;

[0038] The column 2 is fixedly connected to the base 1; one end of the cantilever 3 is fixedly connected to the base 1, and the other end is suspended; the first hydraulic telescopic arm 4, the second hydraulic telescopic arm 6, the third hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com