Flow equalizing device and method for gap flow field in metal revolving body micro-electrochemical machining

A technology of micro electrolysis and gap flow field, applied in metal processing equipment, electrochemical processing equipment, supply of processing working medium, etc. Consistent uniformity of machining, improved stability and the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

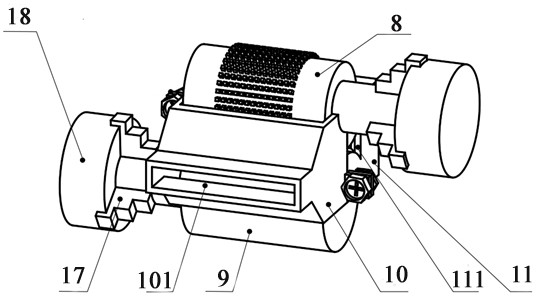

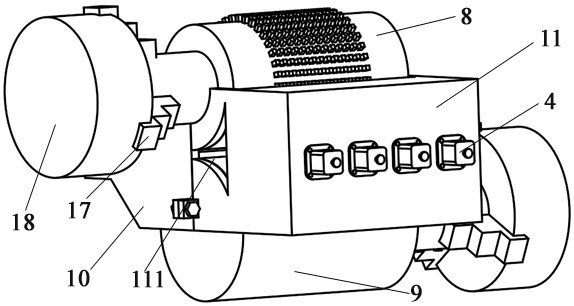

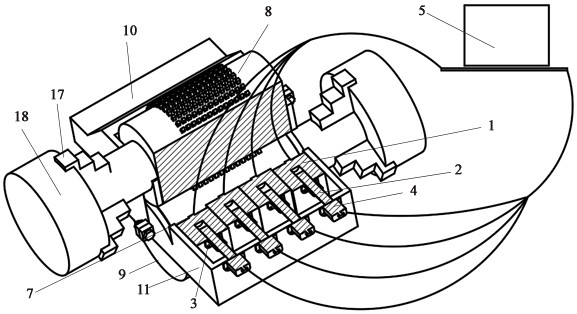

[0028] Such as figure 1 and figure 2 As shown, the gap flow field device in the micro electrolytic machining of metal rotors includes an ultrasonic transducer 8 as a cathode and a metal rotor 9 as an anode. The ultrasonic transducer 8 and the metal rotor 9 are respectively placed in a casing, and the casing It includes a front housing 10 and a rear housing 11, the front housing 10 and the rear housing 11 are fixedly connected by bolts and nuts, and the ultrasonic transducer 8 and the metal rotary body 9 are respectively placed in the front housing 10 and the rear housing Above and below the junction of 11, an electrolyte inlet 101 is opened on the front housing 10, and an electrolyte outlet 111 is opened on both sides of the junction between the rear housing 11 and the front housing 10, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com