Follower rest device for horizontal gantry lathe

A technology for horizontal lathes and tool holders, which is applied in the direction of auxiliary devices, turning equipment, tool holder accessories, etc., can solve the problems affecting the machining accuracy and application range of lathes, unfavorable thick and long axis machining, and limitation of machining capacity, etc., to achieve It is convenient for mass production and promotion, easy to operate and maintain, and the effect of increasing the diameter range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

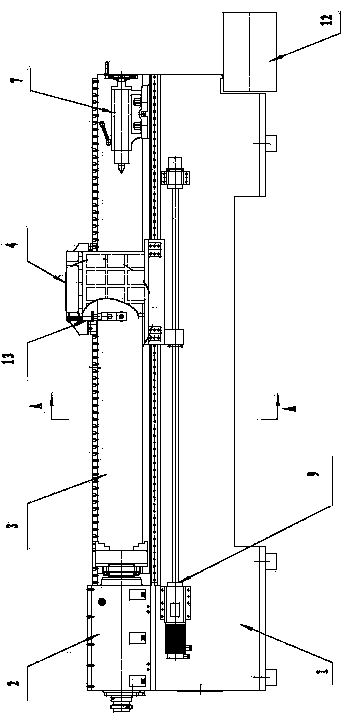

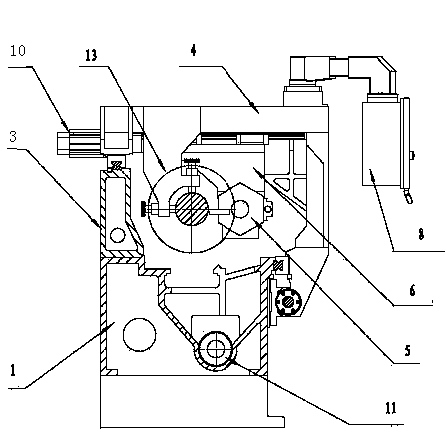

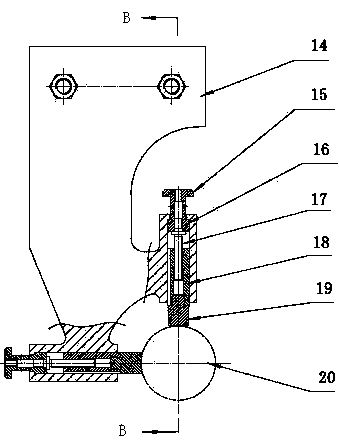

[0011] from figure 1 is a structural schematic diagram of the present invention and figure 2 It can be seen from the A-A sectional view that the present invention includes a gantry frame 4 and a heel tool rest 13, the gantry frame 4 is installed on two horizontal guide rails of the front of the bed 1 and the rear support wall 3, and the rear support wall 3 is behind the bed 1. A gantry feeding device 9 is installed between the gantry frame 4 and the bed 1 , and the gantry feeding device 9 drives the gantry frame 4 to move laterally along the horizontal guide rail on the bed 1 . The gantry horizontal lathe of the present invention mainly includes a bed 1, a headstock 2, a rear support wall 3, a gantry frame 4, a tool rest 5, a small pallet 6, a tailstock 7, an electric control part 8, a gantry feed device 9, Tool rest feeding device 10, spiral chip removal device 11, waste material box 12, follower tool rest 13 and other parts. The installation position of headstock 2 and ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com