Flexible transparent piezoelectric composite film, transparent stretchable ultrasonic transducer and preparation method thereof

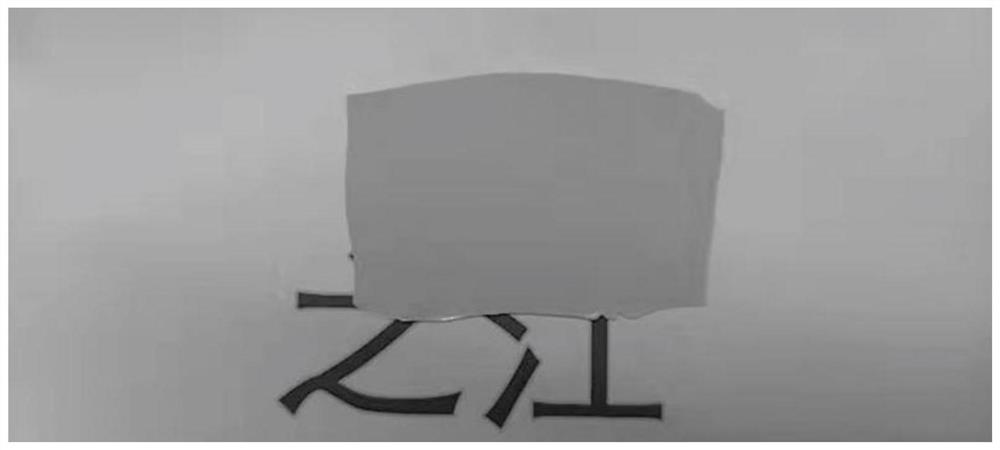

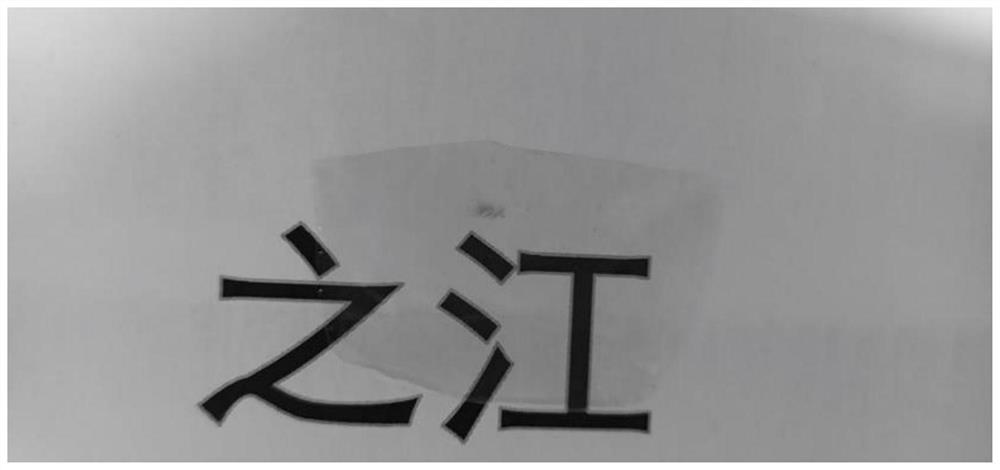

A piezoelectric film, transparent polymer technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc. Solve the problems of insufficient polarization, low-voltage electrical properties, and non-transparency of composite piezoelectric films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a flexible transparent composite piezoelectric film provided in this embodiment includes:

[0041] 1) with AgNO 3 As the solute, with ethanol as the solvent, AgNO with a concentration range of 5mol / L was prepared. 3 solution;

[0042] 2) In the dark, mix PMN-PT piezoelectric single crystal particles with AgNO with a concentration of 5mol / L in the above step 3 The solution was mixed and stirred for 50 minutes to make the mixture uniform;

[0043] 3) irradiate the solution described in step 2) with ultraviolet light for 50 minutes, and keep stirring during the process;

[0044] 4) Then use a centrifuge to separate the prepared Ag@PMN-PT heterojunction from the solution described in step 3) above, wash it several times with deionized water, and dry it in a nitrogen atmosphere to finally prepare Ag@PMN -PT heterojunction particle powder, wherein the Ag content in the heterojunction is 10wt%;

[0045] 5) Weigh an appropriate amount of PVDF-TrFE, d...

Embodiment 2

[0052] A method for preparing a flexible transparent composite piezoelectric film provided in this embodiment includes:

[0053] 1) with AgNO 3 As the solute, with ethanol as the solvent, AgNO with a concentration range of 5mol / L was prepared. 3 solution;

[0054] 2) In the dark, mix PMN-PT piezoelectric single crystal particles with AgNO with a concentration of 5mol / L in the above step 3 The solution was mixed and stirred for 50 minutes to make the mixture uniform;

[0055] 3) irradiate the solution described in step 2) with ultraviolet light for 50 minutes, and keep stirring during the process;

[0056] 4) Then use a centrifuge to separate the prepared Ag@PMN-PT heterojunction from the solution described in step 3) above, wash it several times with deionized water, and dry it in a nitrogen atmosphere to finally prepare Ag@PMN -PT heterojunction particle powder, wherein the Ag content in the heterojunction is 10wt%;

[0057] 5) Weigh an appropriate amount of PVDF-TrFE, d...

Embodiment 3

[0064] A method for preparing a flexible transparent composite piezoelectric film provided in this embodiment includes:

[0065] 1) with AgNO 3 As the solute, using ethanol as the solvent, prepare a AgNO3 solution with a concentration range of 0.001mol / L;

[0066] 2) In the dark, mix PMN-PT piezoelectric single crystal particles with AgNO with a concentration of 0.001mol / L in the above step 3 The solution was mixed and stirred for 50 minutes to make the mixture uniform;

[0067] 3) irradiate the solution described in step 2) with ultraviolet light for 50 minutes, and keep stirring during the process;

[0068] 4) Then use a centrifuge to separate the prepared Ag@PMN-PT heterojunction from the solution described in step 3) above, wash it several times with deionized water, and dry it in a nitrogen atmosphere to finally prepare Ag@PMN -PT heterojunction particle powder, wherein the Ag content in the heterojunction is 0.5wt%;

[0069] 5) Weigh an appropriate amount of PVDF-TrF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com