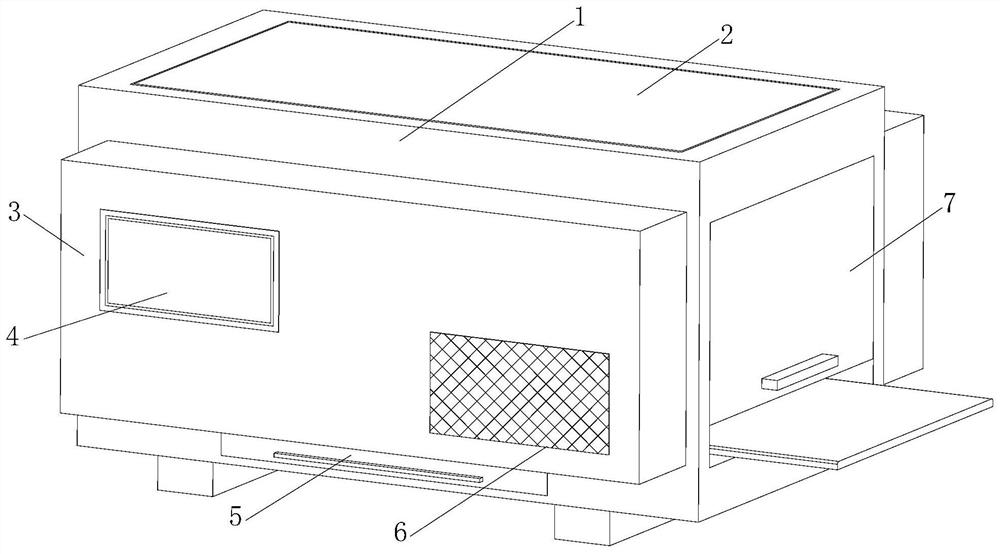

Metal plate derusting and painting processing equipment and using method

A metal sheet and processing equipment technology, applied in spray booths, spray devices, coatings, etc., can solve problems such as unsatisfactory spray paint adhesion, impact on sheet use, low processing efficiency, etc., to improve the sheet paint effect and reduce the amount of particles , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

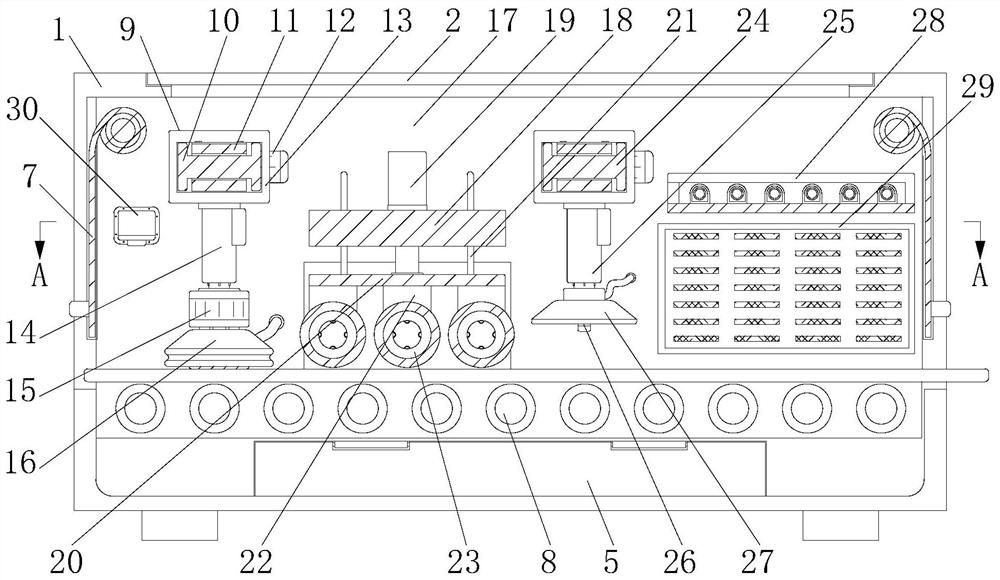

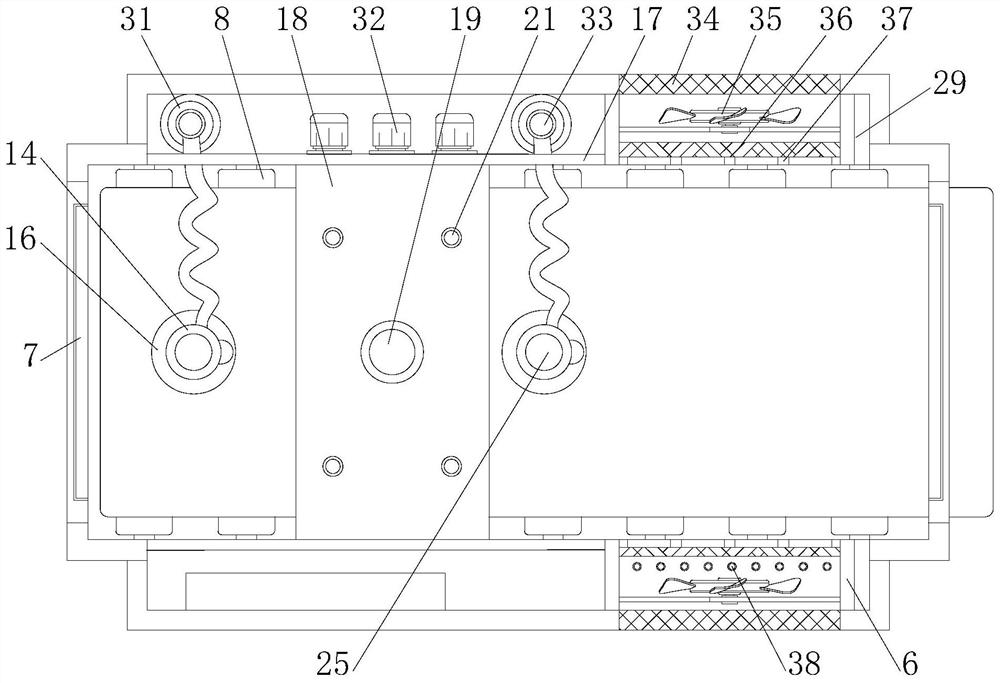

[0037] The bottom of the conveying roller 8 is located on the two side walls of the device body 1 and is also provided with an openable and closable chip plate 5 through the rotating shaft,

[0044] Specifically, the four corners of the upper surface of the driven plate 20 are fixed with a stabilizer bar 21, and the top end of the stabilizer bar 21 penetrates the stabilizer plate 18,

[0059] After the metal plate is polished, the conveying roller 8 continues to run and transport the polished metal plate,

[0060] The metal sheet continues to be conveyed by the conveying roller 8 after being cleaned, and when conveyed under the painting assembly, the second drive

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com