Cobalt selenide, graphite and carbon nitride composite material and preparation method and application thereof

A technology of graphitic carbon nitride and composite materials, applied in the field of photocatalytic materials, can solve the problems of high cost of raw materials, environmental pollution, complicated preparation, etc., and achieve the effects of high solar energy utilization efficiency, low price, and wide light response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

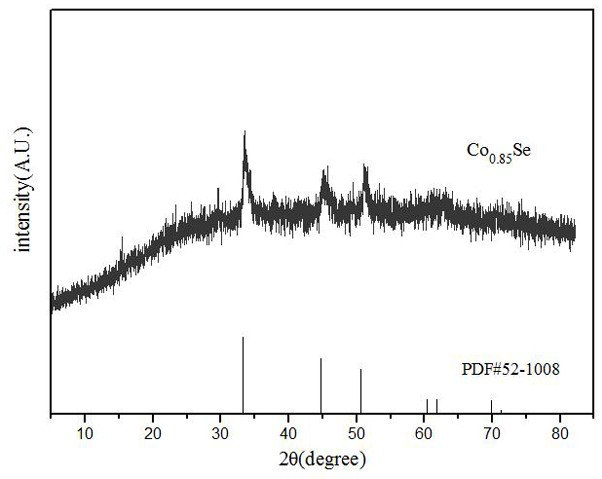

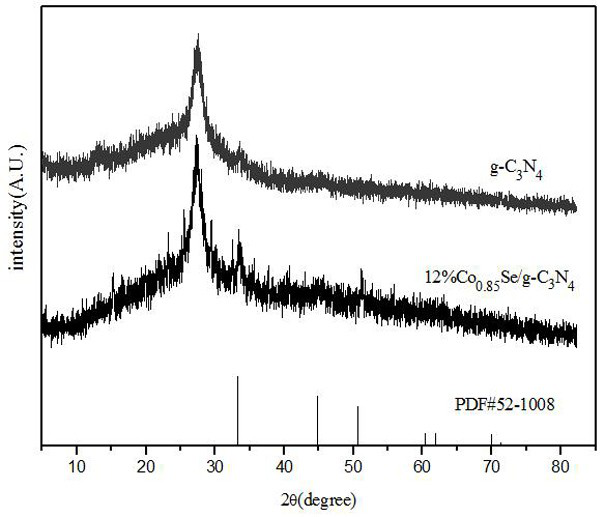

[0035] Dissolve 152mg of cobalt acetate tetrahydrate and 210mg of sodium selenite in 30ml of ethylene glycol solvent, and then transfer the mixture to a stainless steel autoclave after stirring for 5 minutes, seal it and keep it at 200 °C for 24 h, cool to room temperature, The resultant was washed and dried in an oven at 60 °C to obtain Co 0.85 Se. Graphite carbon nitride (g-C 3 N 4 ) was prepared by putting 10 g of urea into a 30 ml crucible and calcining at 550 °C for 4 h in a muffle furnace, with a heating rate of 5 °C / min during the calcination process. 6 mg Co 0.85 Se and 50 mgg-C 3 N 4 Dissolved in 5 ml of deionized water and ultrasonicated for 8 h, the ultrasonic power was 400 W, washed and dried, then placed in a muffle furnace for calcination at 320 °C under air conditions for 2 h, the heating rate during the calcination process was 3 °C / min, and 12% co 0.85Se / g-C 3 N 4 target product. Using the same method, a series of composites with different ratio conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com