A device and method for measuring the corrosion rate of steel pipe surface

A technology of corrosion rate and steel pipe, applied in the field of construction engineering, can solve the problems of low economic benefit, inapplicability of corrosion rate measurement, loss of economic benefit, etc., and achieve strong economic benefit, convenient measurement, and flexible measurement position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

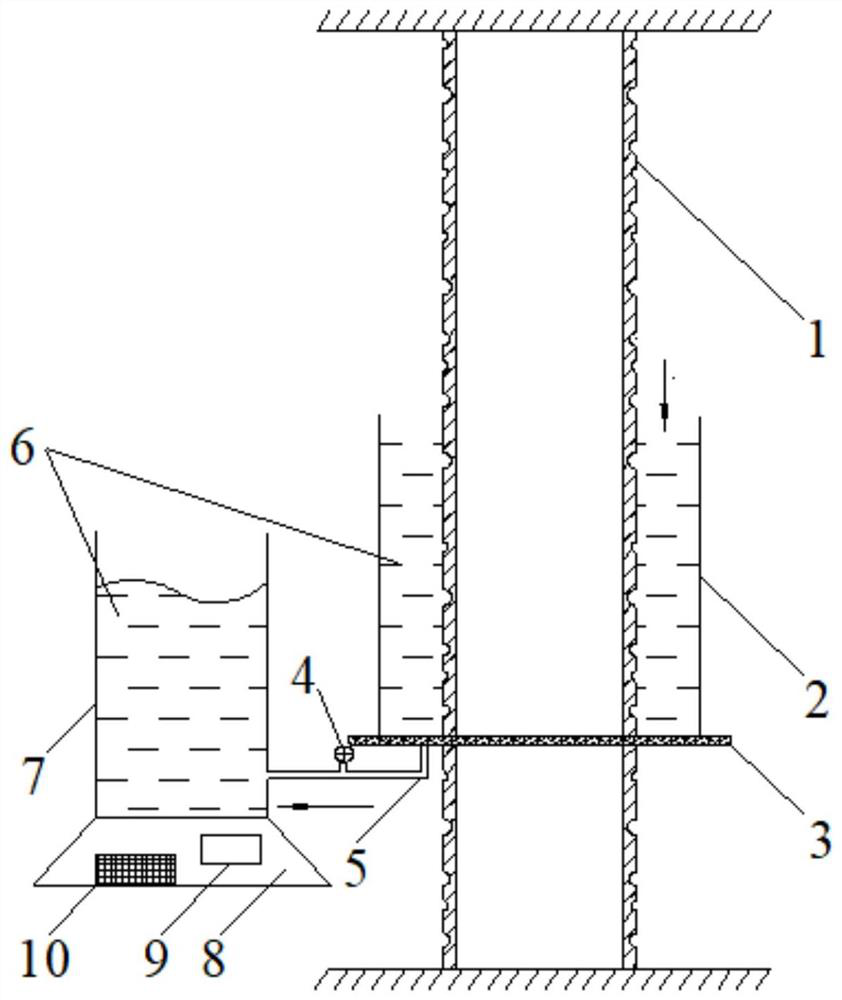

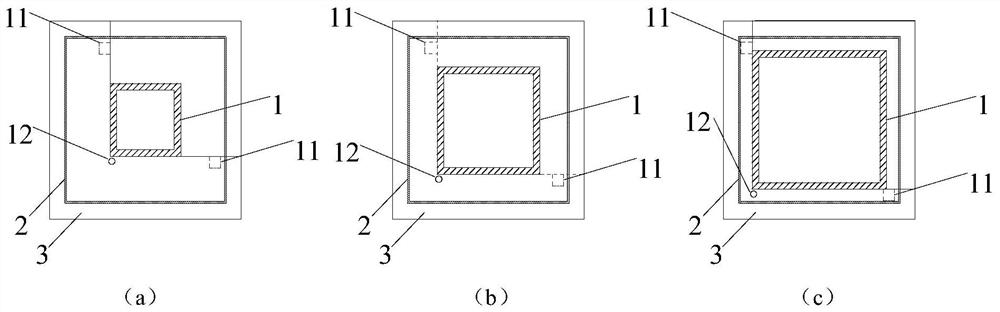

[0048] Example 1, such as figure 1 As shown, a device for measuring the corrosion rate of steel pipe surface in the present invention includes a steel pipe container, a water pipe 5, a water gate 4 and a liquid mass conversion device 8, and the bottom of the steel pipe container is connected to the liquid quality conversion device 8 through a water pipe 5, and the Quantitative measurement liquid is injected into the steel pipe container, and the measurement liquid is discharged into the liquid mass conversion device 8 through the water pipe 5 for weighing and calculation, and is converted into the surface corrosion rate of the steel pipe through the liquid mass conversion device 8 . The steel pipe surface corrosion rate measurement device provided by the present invention converts the mass calculation required to solve the corrosion rate into a volume calculation, and does not cause any damage to the rusted steel pipe column 1 through indirect volume measurement, and solves the...

Embodiment 2

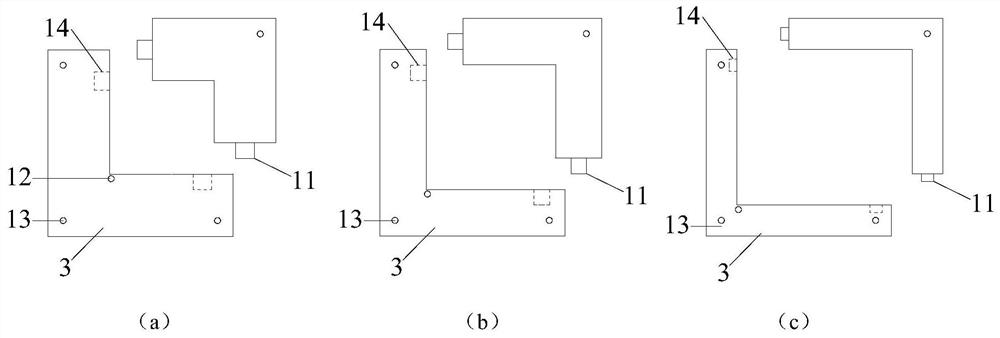

[0071] Embodiment 2, the difference between this embodiment and embodiment 1 is that, as Figure 5-7 As shown, the first connecting plate and the second connecting plate are circular, and the first circumferential baffle and the second circumferential baffle are arc-shaped plates.

[0072] like Figure 8 As shown, in the present embodiment, the liquid mass conversion device 8 includes a graduated cylinder 7, a display screen 9, a keyboard 10, a gravity sensor 15, a signal amplifier 16, a digital-to-analog converter 17, a central processing unit 18 and a power supply 19, and the liquid enters After the measuring cylinder 7, the gravity analog signal is obtained by the gravity sensor 15, which is output to the digital-to-analog converter 17 through the signal amplifier 16 and converted into a digital signal, and the digital signal is transmitted to the central processing unit 18 for calculation, and finally the result is output to the display.

[0073] A method for measuring th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com