Glass tube detector

A detector and glass tube technology, applied in the field of photoelectric detection, can solve the problems of relatively high processing requirements, the reduction of vibration isolation performance and installation accuracy by the vibration-damping barrier, to avoid force damage or functional failure, avoid direct contact, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific examples.

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

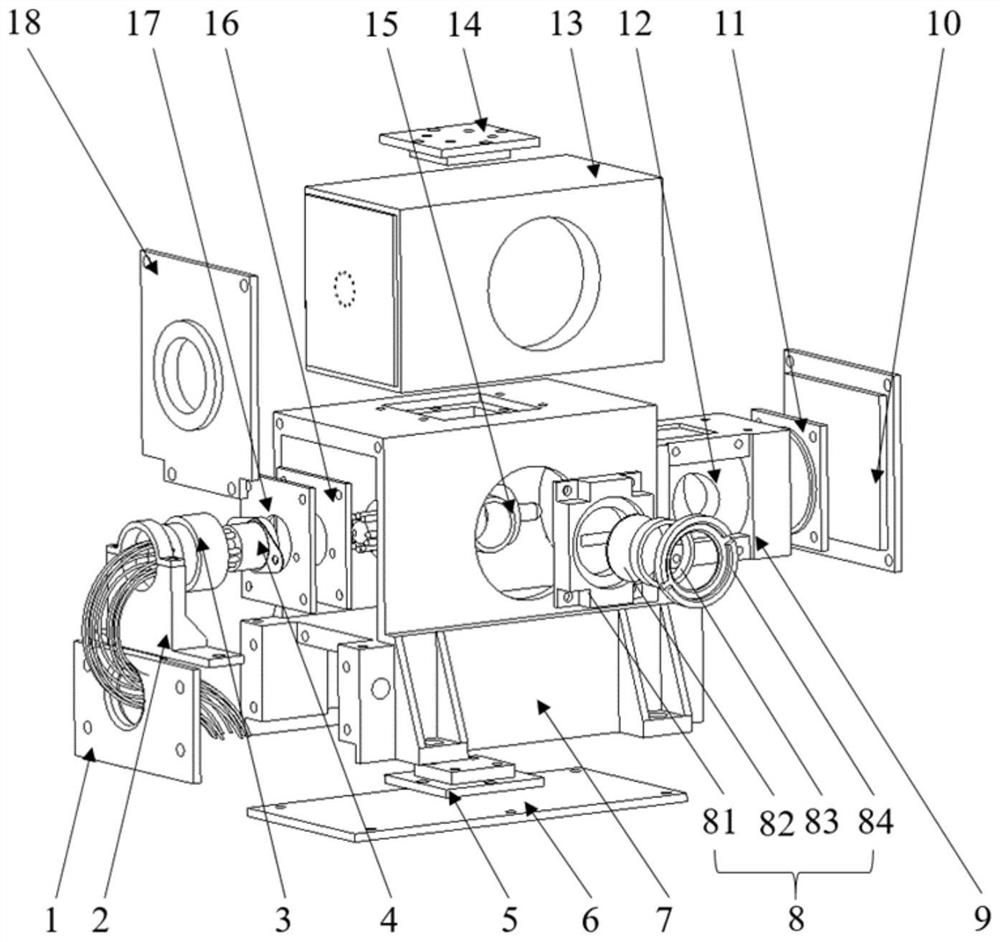

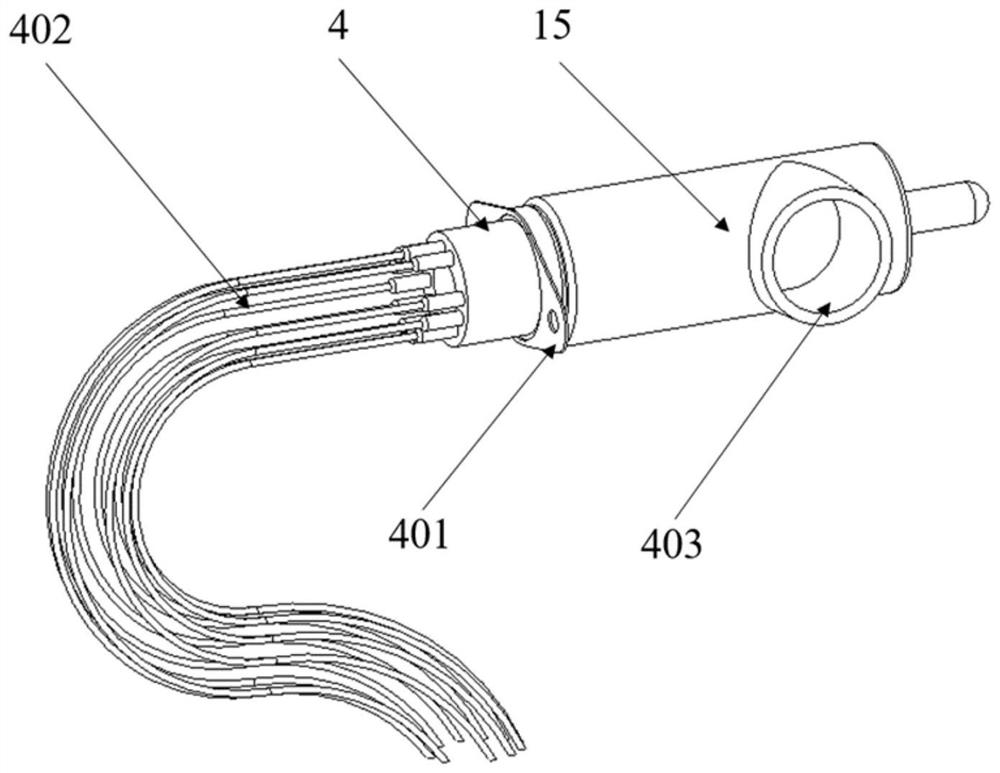

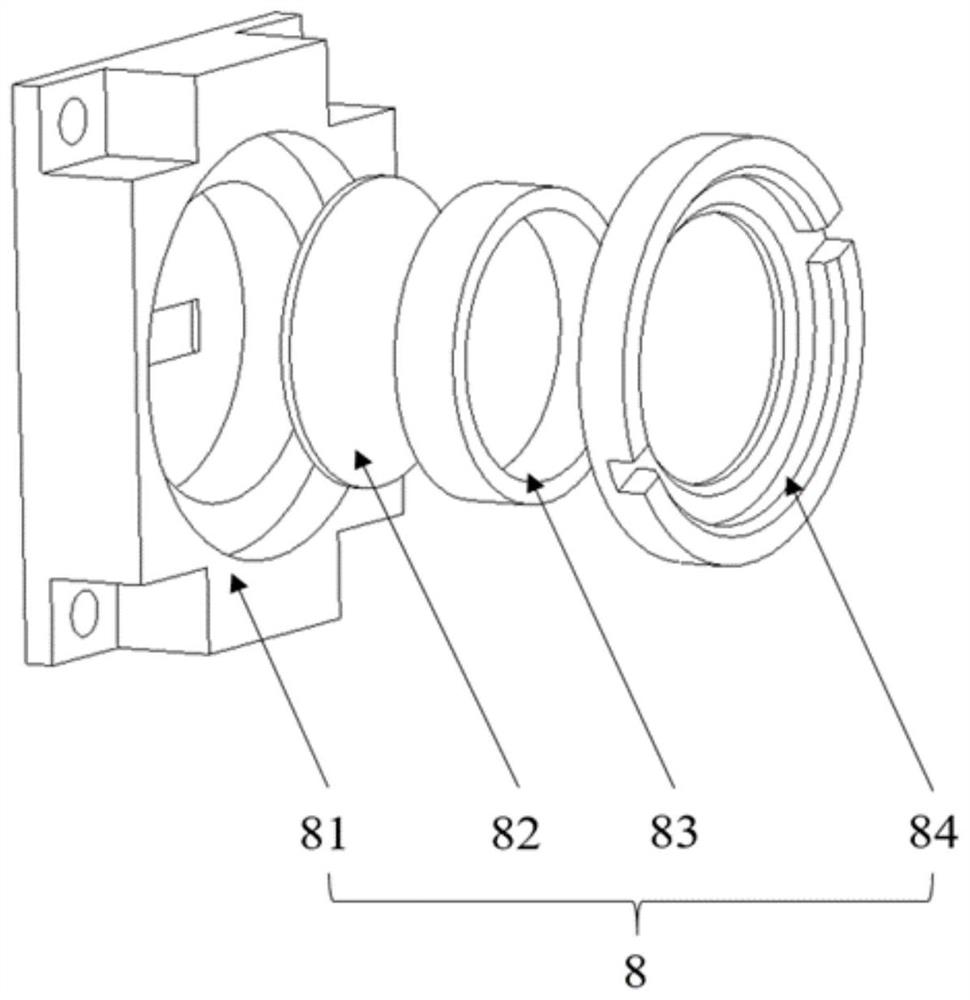

[0044] Such as figure 1 Shown, a kind of glass tube detector comprises: detector assembly (photomultiplier tube base 4 and photomultiplier tube 15), pipe sleeve assembly (pipe sleeve 9, the third pipe sleeve end cap 11, the first adhesive layer 12, The second pipe sleeve end cap 16 and the first pipe sleeve end cap 17), the diaphragm assembly 8 (diaphragm 81, optical filter 82, spacer 83, pressure ring 84), housing assembly (the first outer end cap 1, Wire clamp 2, third rubber block 3, second auxiliary top cover 5, shell 7, third outer end cover 10, second adhesive layer 13, first auxiliary top cover 14 and second outer end cover 18) and other components (PCB board 6, first auxiliary block 19, second auxiliary block 20 and limit screw 21). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com