Automatic double-lifting coil stock uncoiler

An uncoiler and coil material technology, which is applied in the field of automatic double-lifting coil uncoiler, can solve the problems of the uncoiler plate deviates from the coil track, cannot be accurately uncoiled, and the coil edge is not neat, and achieves reduced diameter requirements and automation. The effect of high degree and equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

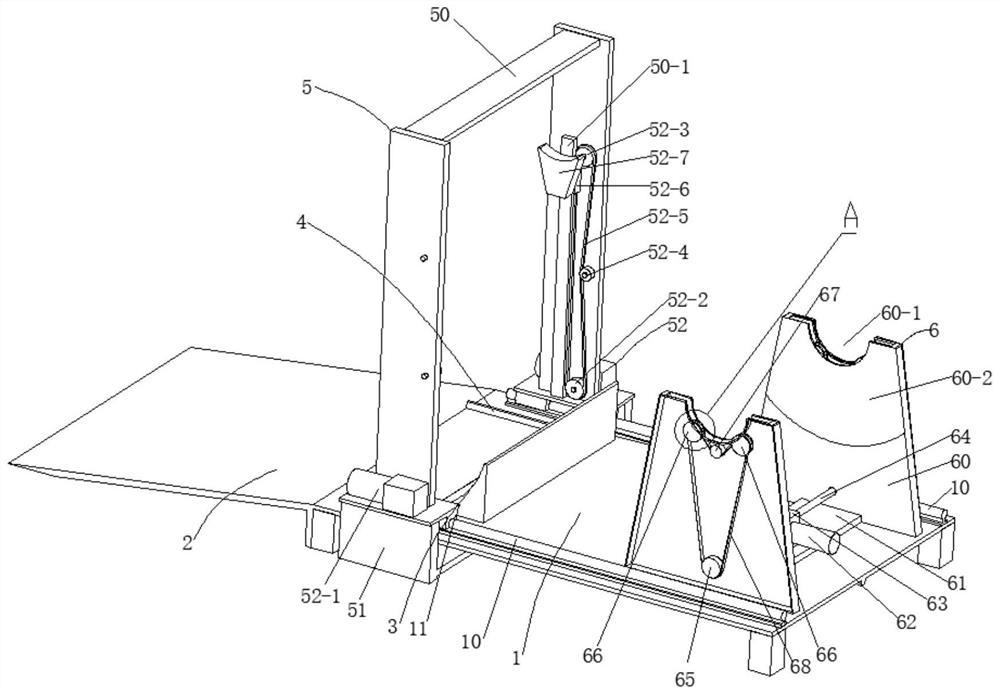

[0043] In the automatic double-lifting coil uncoiler of the present invention, first keep the lifting fork 52-7 in the lifting device 52 at a low position, then hoist the coil or forklift the fork on the cart, and pass the cart loaded with coil The inclined table 2 is pushed onto the base platform 1, and then the coil material is pushed down, so that the coil material is positioned by the arc positioning plate 3 in the front and rear direction, and positioned by the horizontal positioning bar 4 in the left and right direction.

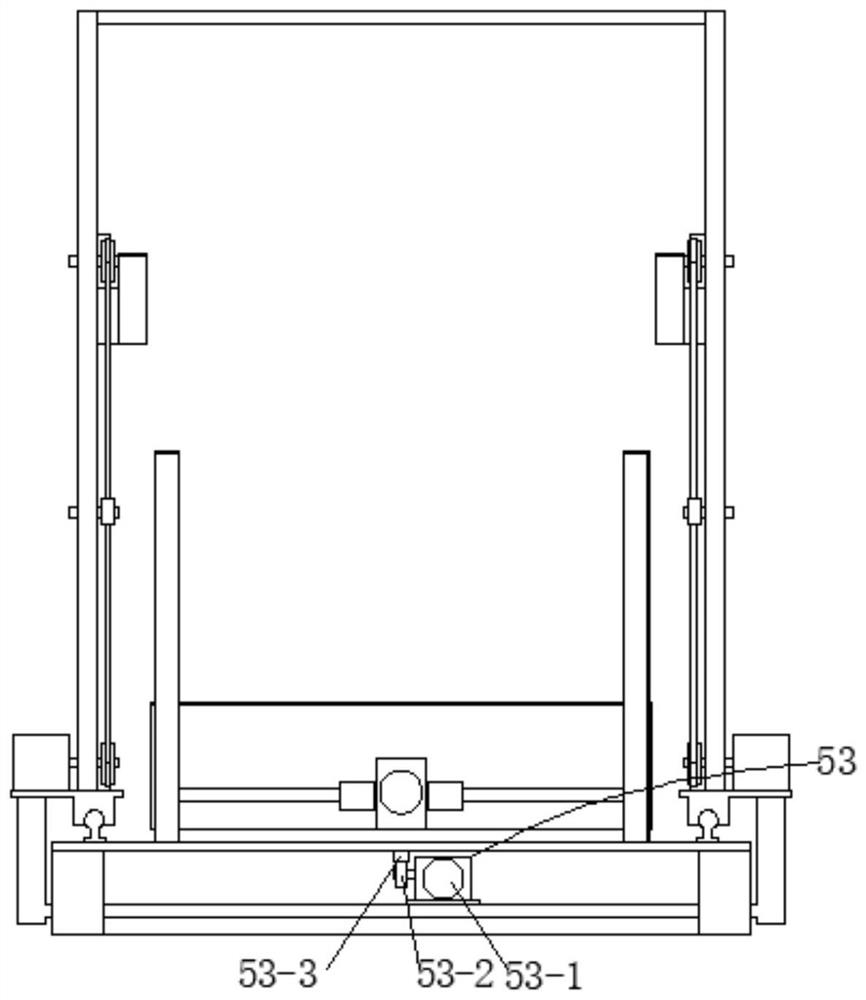

[0044] Then, start the servo motor one 52-1 in the lifting device 52, the servo motor one 52-1 drives the chain 52-5 to move upwards with the slide block 52-6 through the drive sprocket 52-2, and the slide block 52-6 moves upwards with the slide block 52-6. Lifting fork 52-7 moves upwards, then lifting fork 52-7 contacts with the two ends of the shaft inserted into the coil material center, and then coil material continues to move upwards with lifting f...

Embodiment 2

[0052] On the basis of Embodiment 1, the top of the bracket 60 is provided with a groove 60-1 to ensure the safety of the coil material falling; the inside of the bracket 60 is provided with a positioning slide 60-2, so that the coil material board is uncoiled When aligning the left and right positions and positioning, the wear resistance of the bracket 60 is improved at the same time.

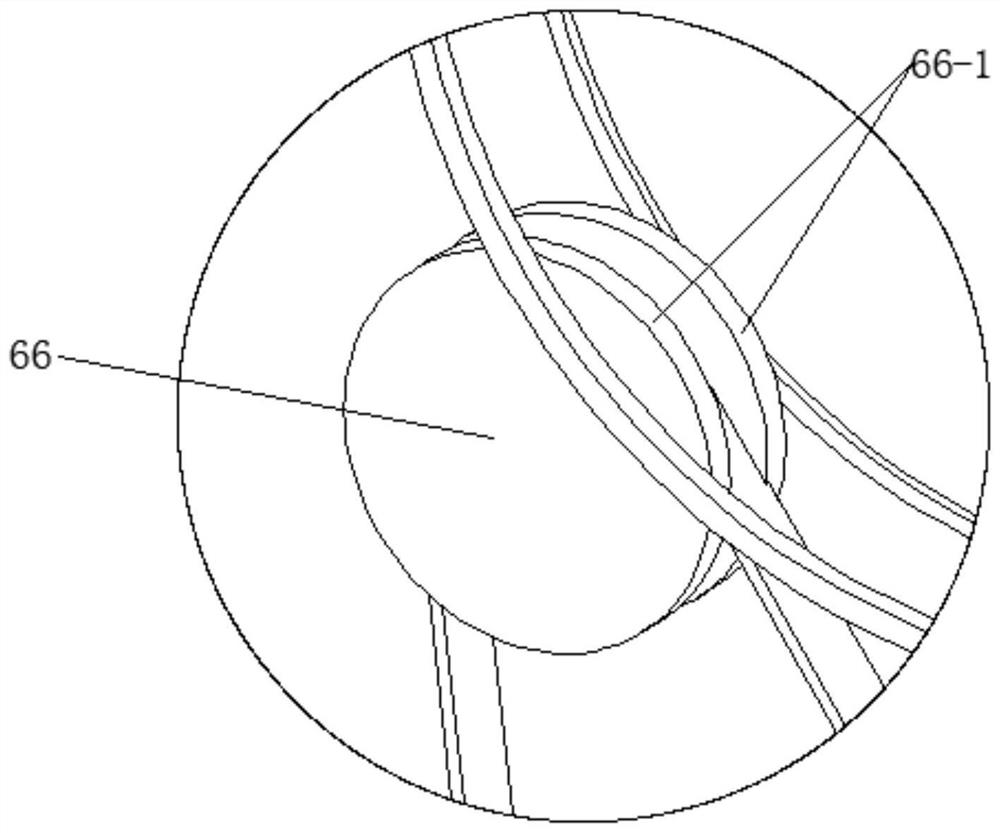

[0053] The two passive synchronous pulleys 66 are I-shaped wheels, and the outer circular surface of the passive synchronous pulley 66 is provided with a knurling structure 66-1, and the outer circular surface exceeds the groove 60-1, ensuring that the two passive synchronous pulleys Timing pulley 66 drive stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com