Track elastic strip fastener defect recognition method, device and computer equipment

A technology for defect identification and fasteners, which is applied to computer components, calculations, character and pattern recognition, etc., can solve the problems of large amount of 3D point cloud data, slow data processing speed, and difficulty in detecting fastener out-of-position defects. Improved defect detection rate, fast detection speed, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

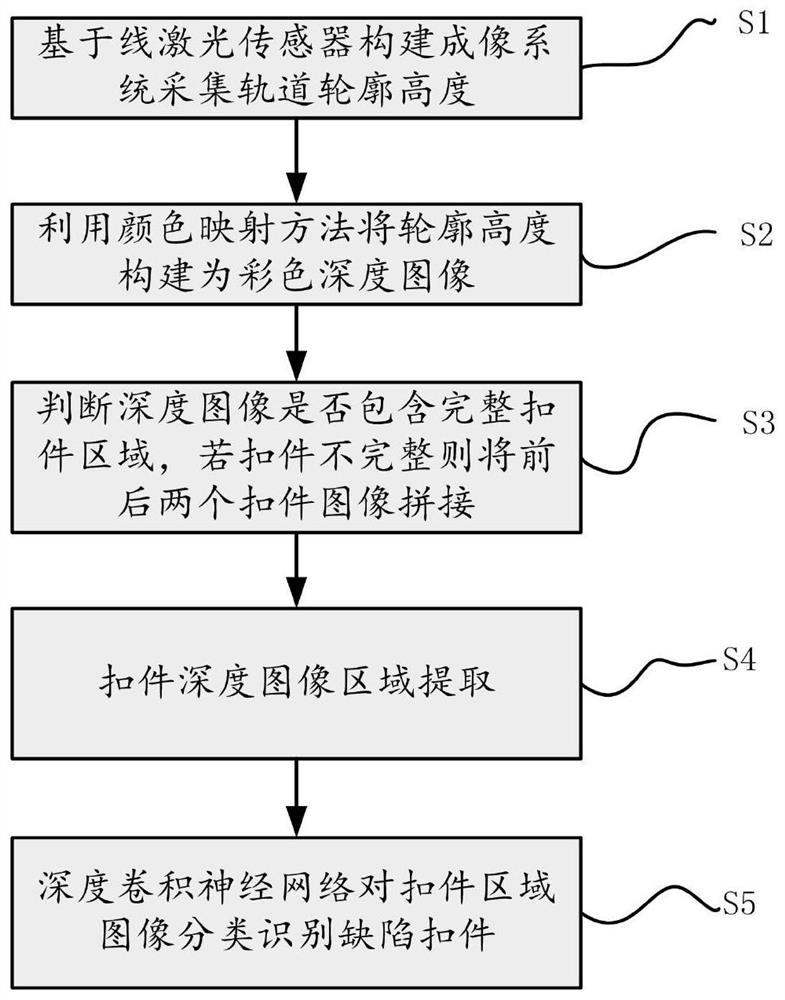

[0065] see figure 1 , an embodiment of the present invention provides a method for identifying defects of rail clip fasteners, the method comprising:

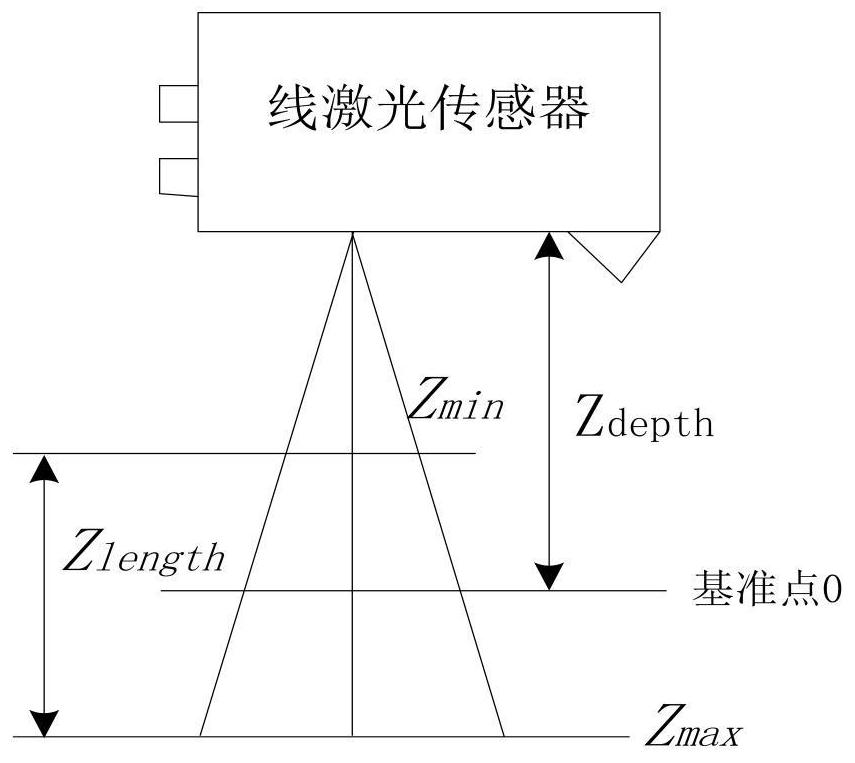

[0066] S1. Construct an imaging system based on a line laser sensor to collect track profile height.

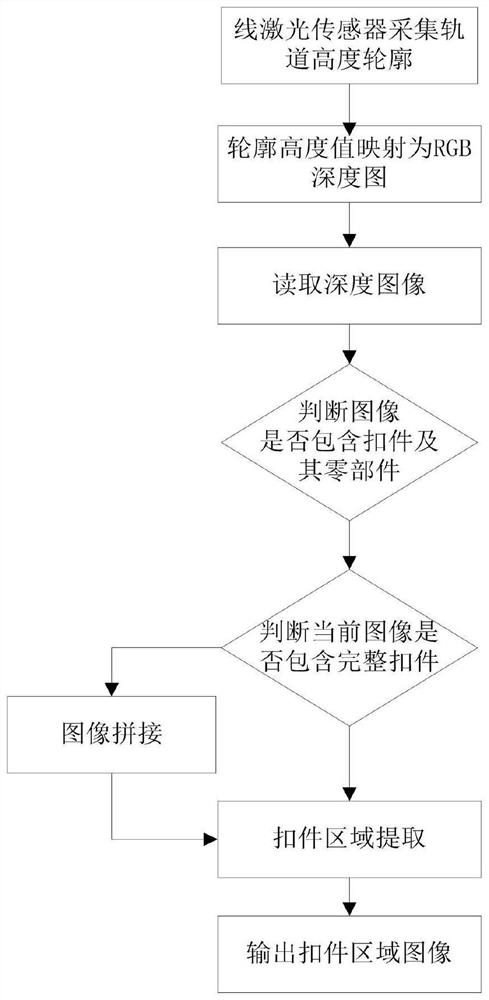

[0067] S2. Using a color mapping method to construct the contour height into a color depth image.

[0068] S3. Determine whether the depth image contains a complete fastener area, and if the fastener is incomplete, splicing the front and rear fastener images.

[0069] S4. Extracting the fastener depth image area.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com