Carbon fiber gel material as well as preparation method and application thereof

A technology for gel materials and fiber materials, which is applied in the fields of fiber chemical characteristics, chemical instruments and methods, rayon manufacturing, etc., can solve the problems of small adsorption capacity, secondary pollution, and no obvious increase in adsorption capacity, and achieves the preparation method. Simple, excellent adsorption performance, fast adsorption rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Carbonize the ZIF-8-PAN fiber at 240°C under an inert atmosphere with a heating rate of 3°C / min to obtain an easily dispersible fiber material.

[0033] Step 2: Add 180 mg of the fiber material obtained in Step 1 and 15 mg of GO into a mixed solution of 15 ml of water / tert-butanol (volume ratio 4:1), and stir evenly to obtain a dispersion.

[0034] Step 3, pour the dispersion liquid obtained in step 2 into a mold, freeze in a refrigerator for 12 hours, and then freeze-dry for 48 hours to obtain an airgel;

[0035] Step 4: carbonize the airgel obtained in step 3 at 900° C. under an inert gas with a heating rate of 3° C. / min to obtain a carbon fiber gel material.

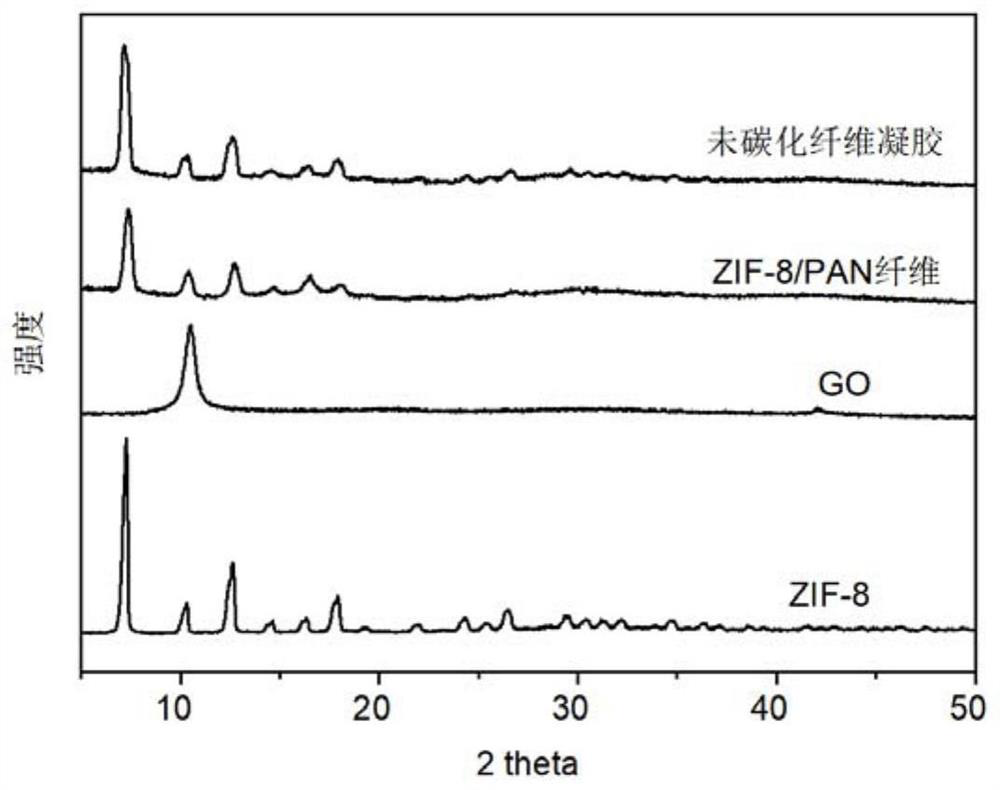

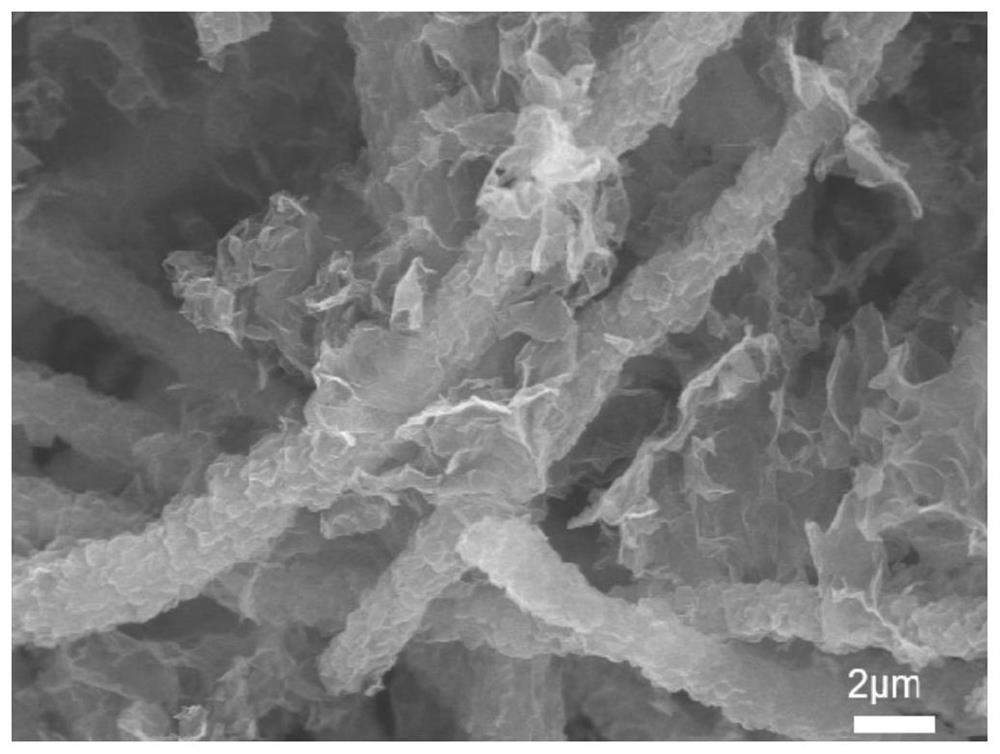

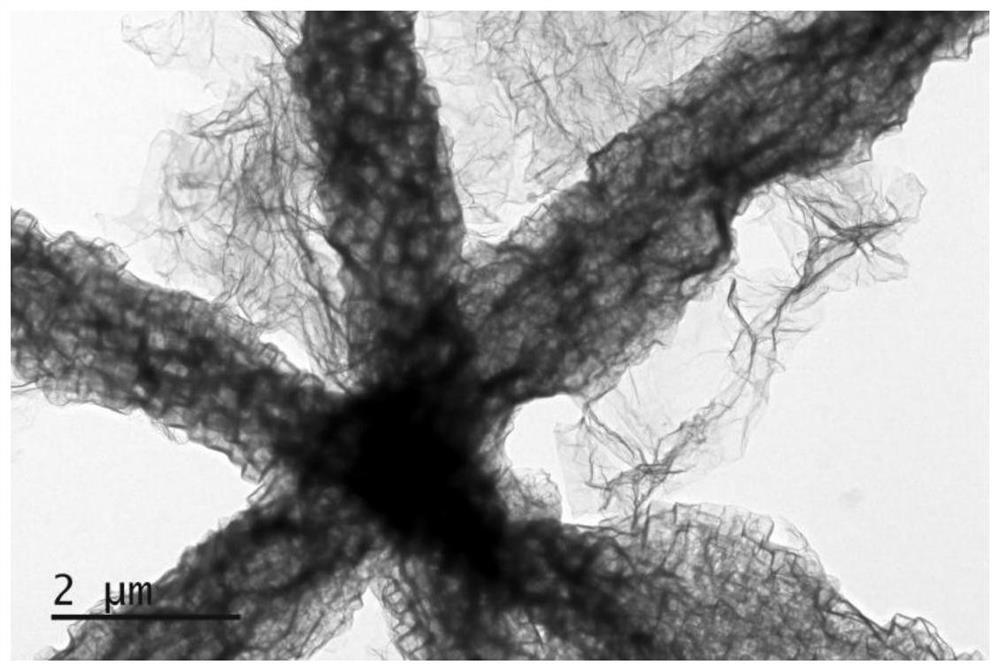

[0036] figure 1 XRD pattern for ZIF-8, ZIF-8-PAN, GO, airgel. It can be seen from the figure that the airgel contains ZIF-8 and GO. figure 2 It is the scanning electron microscope picture of the porous carbon fiber gel material, image 3 It is the transmission electron micrograph of the porous carb...

Embodiment 2

[0042] Step 1: Carbonize the ZIF-8-PAN fiber at 230°C under an inert atmosphere with a heating rate of 2°C / min to obtain an easily dispersible fiber material.

[0043] Step 2: Add 165 mg of the fiber material obtained in Step 1 and 15 mg of GO into a mixed solution of 15 ml of water / tert-butanol (volume ratio 4:1), and stir evenly to obtain a dispersion.

[0044] Step 3, pour the dispersion liquid obtained in step 2 into a mold, freeze in a refrigerator for 12 hours, and then freeze-dry for 48 hours to obtain an airgel;

[0045] Step 4: carbonize the airgel obtained in step 3 at 700° C. under an inert gas with a heating rate of 2° C. / min to obtain a carbon fiber gel material. The measured density of the material is about 9.96mg / cm 3 , at room temperature, the adsorption rate of ethanol is 6732%, the adsorption rate of DMF is 9987%, the adsorption rate of n-hexane is 10388%, and the adsorption rate of pump oil is 13832%.

Embodiment 3

[0047] Step 1, under an inert atmosphere, carbonize the ZIF-8-PAN fiber at 250°C with a heating rate of 5°C / min to obtain an easily dispersible fiber material.

[0048] Step 2: Add 195 mg of the fiber material obtained in Step 1 and 30 mg of GO into a mixed solution of 15 ml of water / tert-butanol (volume ratio 4:1), and stir evenly to obtain a dispersion.

[0049] Step 3, pour the dispersion liquid obtained in step 2 into a mold, freeze in a refrigerator for 12 hours, and then freeze-dry for 48 hours to obtain an airgel;

[0050]Step 4: carbonize the airgel obtained in step 3 at 900° C. under an inert gas with a heating rate of 10° C. / min to obtain a carbon fiber gel material. The measured density of the material is about 10.34mg / cm 3 , At room temperature, the adsorption rate of ethanol is 7139%, the adsorption rate of DMF is 10255%, the adsorption rate of n-hexane is 9567%, and the adsorption rate of pump oil is 13521%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com