PH response type corrosion inhibition capsule based on metal polyphenol network structure and preparation and application of pH response type corrosion inhibition capsule

A network structure, metal technology, applied in the direction of microcapsule preparation, microsphere preparation, etc., can solve the problems of cumbersome process, leakage of corrosion inhibitor molecules, etc., and achieve the effect of low price, easy surface modification, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preferred preparation process is:

[0035] 1) First add a certain amount of cetyltrimethylammonium bromide into water, raise the temperature to 80°C, then add NaOH, and stir vigorously for 10-20 minutes.

[0036] 2) Then tetraethyl orthosilicate was added dropwise, reacted at 80° C. for two hours, and the obtained white solid was obtained by suction filtration after cooling.

[0037] 3) Calcining the collected solid in a muffle furnace for 5 h.

[0038] The preferred amount of cetyltrimethylammonium bromide added is 1 g, and the amount of tetraethylorthosilicate is 5 mL.

[0039] The preferred stirring speed is 8000 rpm.

[0040] The preferred calcination temperature is 550°C, and the heating rate is 1°C / min.

[0041] A preparation method of a HMS-based benzotriazole drug-carrying system of the present invention: dissolve benzotriazole in an ethanol solution, then add the HMS suspension prepared above, pump it to a vacuum state by a vacuum water pump, and After ...

Embodiment 1

[0053] Embodiment 1: the preparation of corrosion inhibitor capsule

[0054] 1) Dissolve 1g of hexadecyltrimethylammonium bromide in water, raise the temperature to 80°C, then add NaOH, stir vigorously for 10-20 minutes, then add 5ml of tetraethyl orthosilicate dropwise, at 80°C The reaction was stirred for two hours, and the obtained white solid was filtered by suction after cooling. The collected solid was heated up to 550° C. at a rate of 1° C. / min in a muffle furnace, and continuously calcined for 5 hours to obtain mesoporous silica.

[0055] 2) Take 1g of calcined mesoporous silica and 1.6g of benzotriazole and mix well in a 40ml three-necked flask, stir and load under vacuum for 24h, take out and centrifuge, wash with deionized water three times, and bake at 60°C Dry and set aside.

[0056] 3) Take the prepared HMS@BTA and configure it into 1mL dispersion system. After vortexing for 30s, add 300uL tannic acid first, and then add 500uL ferric ions after the tannic acid ...

Embodiment 2

[0057] Embodiment 2: the selection of number of repetitions in complexing process

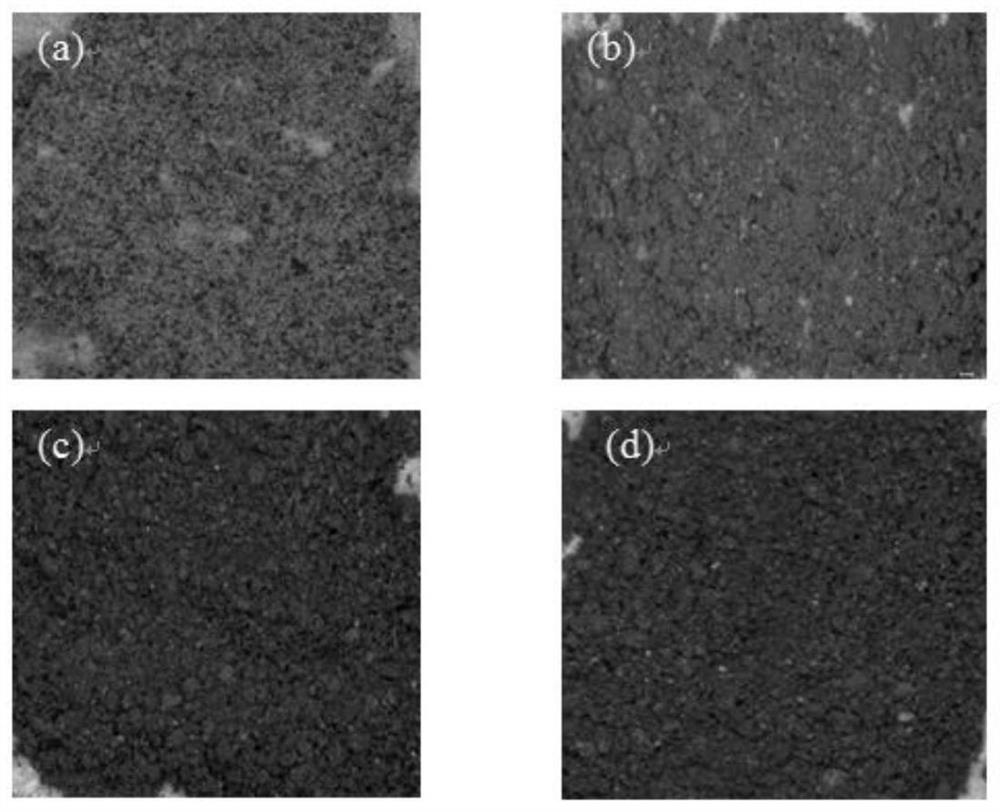

[0058] According to the preparation method described in Example 1, the complexation process was repeated several times to be embodied three times, five times, ten times and fifteen times. After the above steps are completed, the prepared corrosion inhibitor capsules are observed by optical electron microscope in turn, and the results are as follows: figure 1 As shown, (a), (b), (c), and (d) in the figure respectively represent the optical images of the corrosion inhibitor capsules prepared for three, five, ten and fifteen times of complexation. When the number of times of complexation is less than five times, it can be seen under the optical microscope that the prepared corrosion inhibitor capsule presents gray and white colors, and when the number of times of complexation reaches more than ten times, the entire capsule is uniformly black. It shows that if the number of complexation is too sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com