Health-care mattress and preparation method thereof

A mattress and health care technology, applied in the field of mattresses, can solve the problems of poor air permeability of mattresses, affecting people's sleep, and detrimental to physical health, and achieving appropriate softness and resilience, moderate hardness and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

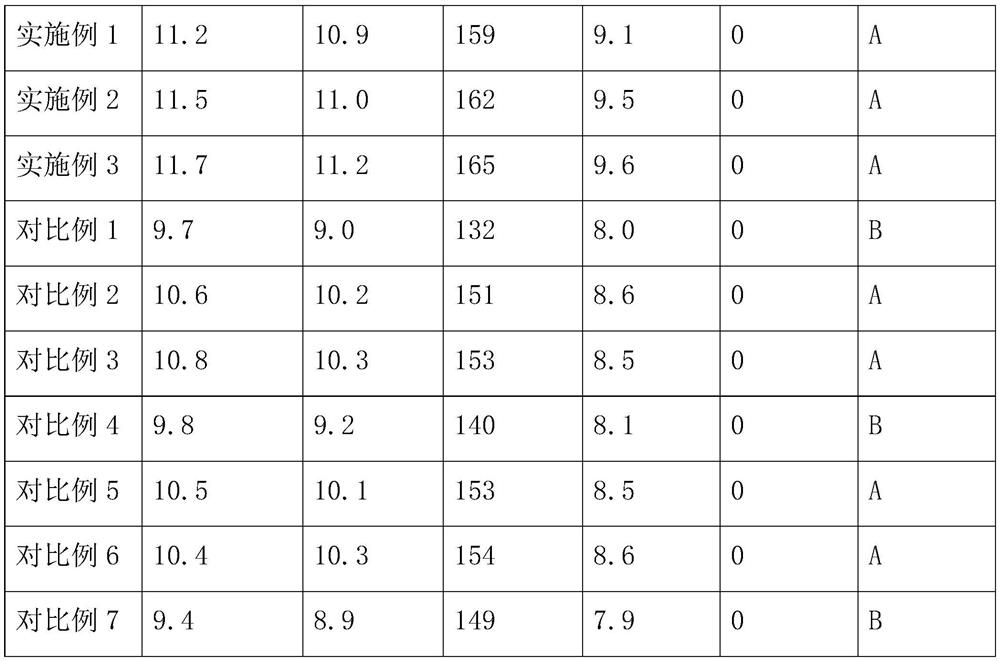

Embodiment 1

[0032] Composition of raw materials (parts by weight): 10 parts of modified bamboo charcoal fiber, 100 parts of low-density polyethylene, 5 parts of diatom mud, 2 parts of n-heptane, 0.1 part of triethanolamine, 3 parts of traditional Chinese medicine essential oil, tert-butyl benzoyl peroxide 0.01 part of ester.

[0033] The preparation method of modified bamboo charcoal fiber is as follows:

[0034] S1. Pretreatment: Soak 20g of bamboo charcoal fiber in 0.5wt% NaOH solution for 20min, take it out and wash it;

[0035] S2. The deposition of magnetic nanoparticles: After mixing 100mL 2mol / L ferric chloride and 100mL 1mol / L ferrous chloride solution, add 15g of pretreated bamboo charcoal fiber, stir for 10min, add dropwise 20wt% ammonia solution until the pH is 8. Introduce oxygen, the ventilation rate is 1L / min, control the reaction temperature to 50°C, filter, and after the solid is calcined at 300°C for 3 hours, the bamboo charcoal fiber deposited with magnetic nanoparticle...

Embodiment 2

[0044] Raw material composition (parts by weight): 30 parts of modified bamboo charcoal fiber, 200 parts of low-density polyethylene, 10 parts of diatom mud, 4 parts of n-pentane, 0.2 part of diethanolamine, 5 parts of traditional Chinese medicine essential oil, and 0.02 part of methyl ethyl ketone peroxide.

[0045] The preparation method of modified bamboo charcoal fiber is as follows:

[0046] S1. Pretreatment: Soak 20g of bamboo charcoal fiber in 2wt% NaOH solution for 30min, take it out and wash it;

[0047] S2. Deposition of magnetic nanoparticles: After mixing 100mL 2mol / L ferric chloride and 100mL 1mol / L ferrous chloride solution, add 15g of pretreated bamboo charcoal fiber, stir for 30min, add dropwise 20wt% ammonia solution until the pH is 11. Introduce oxygen, the ventilation rate is 2L / min, control the reaction temperature to 70°C, filter, and after the solid is calcined at 400°C for 4 hours, the bamboo charcoal fiber deposited with magnetic nanoparticles is obtain...

Embodiment 3

[0056] Composition of raw materials (parts by weight): 20 parts of modified bamboo charcoal fiber, 150 parts of low-density polyethylene, 7 parts of diatom mud, 3 parts of petroleum ether, 0.15 parts of polyvinyl alcohol, 4 parts of traditional Chinese medicine essential oil, 0.015 parts of azobisisoheptanonitrile share.

[0057] The preparation method of modified bamboo charcoal fiber is as follows:

[0058] S1. Pretreatment: Soak 20g of bamboo charcoal fiber in 1wt% NaOH solution for 25min, take it out and wash it;

[0059] S2. The deposition of magnetic nanoparticles: After mixing 100mL 2mol / L ferric chloride and 100mL 1mol / L ferrous chloride solution, add 15g of pretreated bamboo charcoal fiber, stir for 20min, add dropwise 20wt% ammonia solution until the pH is 10. Introduce oxygen, the ventilation rate is 1.2L / min, control the reaction temperature to 60°C, filter, and after the solid is calcined at 350°C for 3.5h, the bamboo charcoal fiber deposited with magnetic nanopa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com