Optical fiber Fabry-Perot total temperature probe for dynamic total temperature measurement and manufacturing method thereof

An optical fiber and dynamic technology, applied in the direction of measuring heat, measuring devices, thermometers, etc., can solve the problems of increasing sensor size, affecting the temperature measurement effect, and increasing the difficulty of assembly, so as to reduce the volume, improve the sensitivity, and reduce the difficulty of installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

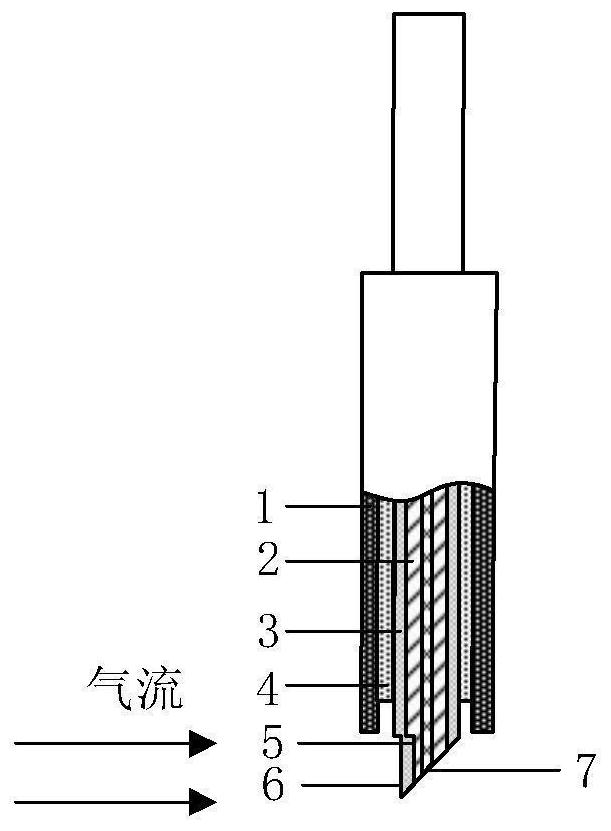

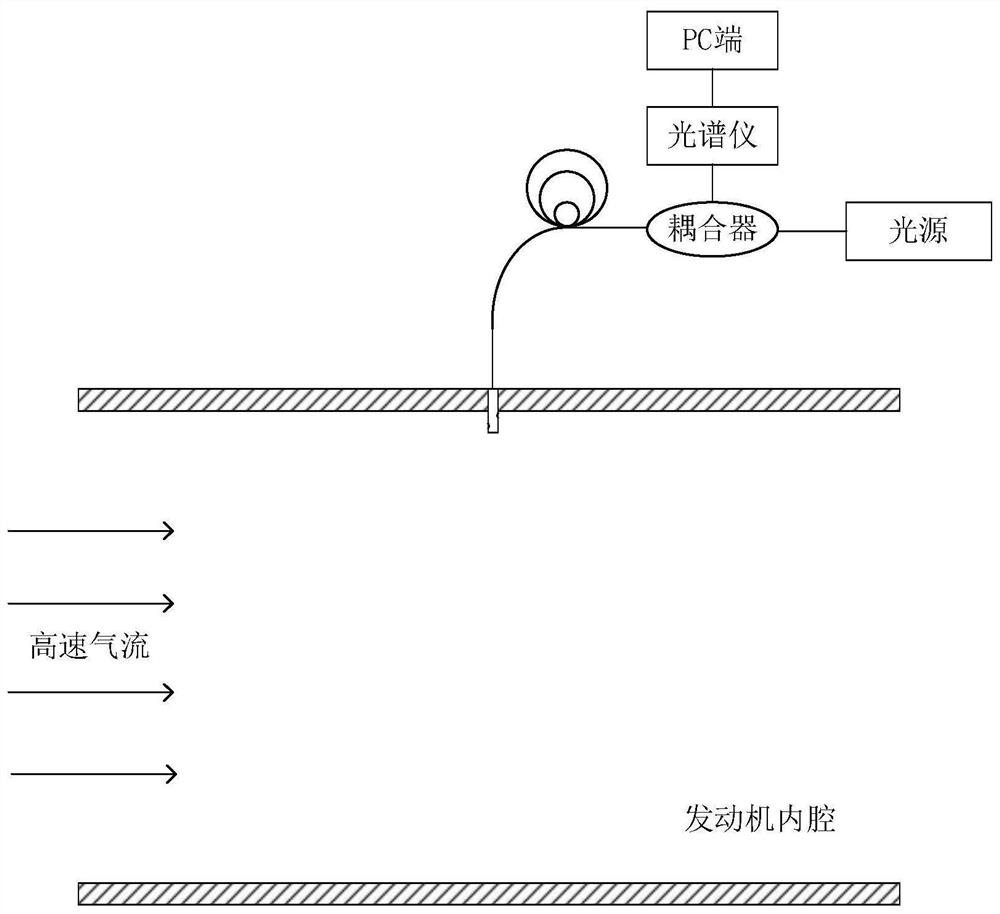

[0042] see Figure 1 to Figure 5 , a fiber optic method-Perco total temperature probe for dynamic total temperature measurement, including a capillary steel tube 1, a transmission optical fiber 2 and a high thermo-optic coefficient film 3.

[0043] The capillary steel pipe 1 is a cylindrical body.

[0044] The transmission optical fiber 2 is bonded to the capillary steel pipe 1 . One end of the transmission optical fiber 2 extends out of the capillary steel pipe 1, which is denoted as the first extension end.

[0045] There is a gap between the capillary steel pipe 1 and the transmission optical fiber 2 .

[0046] The side of the transmission fiber 2 is provided with a first notch, and the notch extends to the end surface of the first extension end.

[0047] The transmission optical fiber 2 is coated with a high thermo-optic coefficient film 3 to form an integrated fiber-film structure.

[0048] The end of the fiber-film integrated structure extending out of the capillary ...

Embodiment 2

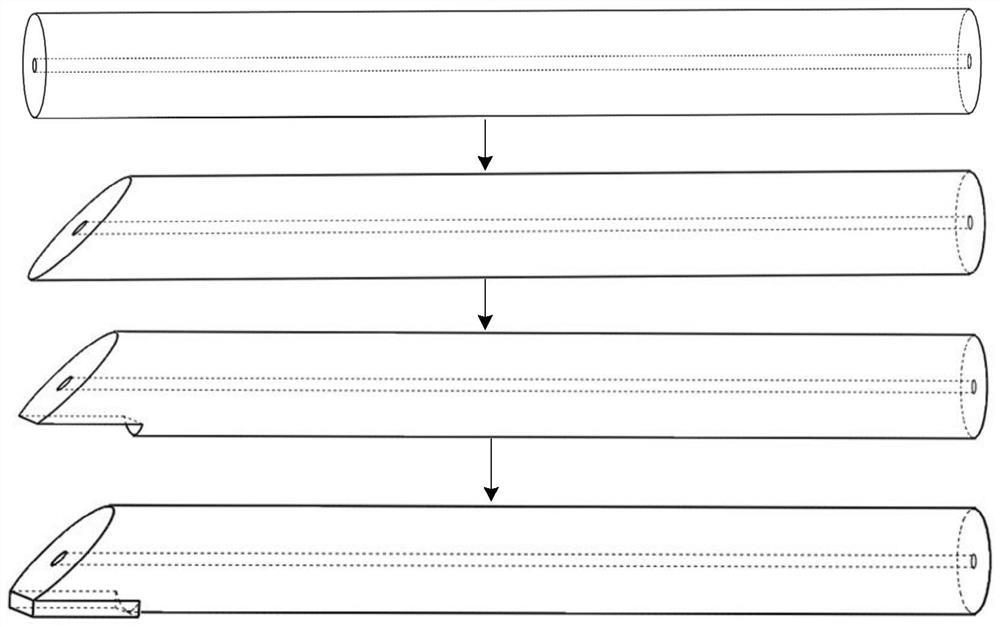

[0056] The method for making the optical fiber method-Perkin probe for dynamic total temperature measurement comprises the following steps:

[0057] 1) Process the end face of the optical fiber to form a beveled end face 7; the processing includes cutting and grinding.

[0058] 2) Process the side of the transmission fiber 2, so as to open a gap on the side of the transmission fiber 2, and the gap extends to the end face of the extension end;

[0059] 3) A layer of high thermo-optic coefficient film 3 is coated on the gap of the transmission fiber 2, thereby forming an integrated fiber-film structure; the surface of the gap of the transmission fiber and the surface of the high thermo-optic coefficient film form a fiber-optic cavity;

[0060] 4) placing the transmission optical fiber 2 in the capillary steel pipe 1, and extending the first extension end of the transmission optical fiber 2 out of the capillary steel pipe 1;

[0061] 5) Apply high-temperature glue 4 between the ...

Embodiment 3

[0064] An optical fiber method-Perco total temperature probe for dynamic total temperature measurement, comprising a capillary steel tube 1, a transmission optical fiber 2 and a high thermo-optic coefficient film 3.

[0065] The capillary steel pipe 1 is a cylindrical body.

[0066] The transmission optical fiber 2 is bonded to the capillary steel pipe 1 . One end of the transmission optical fiber 2 extends out of the capillary steel pipe 1, which is denoted as the first extension end.

[0067] There is a gap between the capillary steel pipe 1 and the transmission optical fiber 2 .

[0068] The side of the transmission fiber 2 is provided with a first notch, and the notch extends to the end surface of the first extension end.

[0069] The transmission optical fiber 2 is coated with a high thermo-optic coefficient film 3 to form an integrated fiber-film structure.

[0070] The outer surface 5 of the first notch of the optical fiber and the coated surface 6 form an optical fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com