Cavity type heat absorber and heat absorbing and storing system

A heat absorber and cavity technology, which is applied in the field of cavity heat absorbers and heat absorption and storage systems, can solve problems such as low heat absorption efficiency and achieve the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

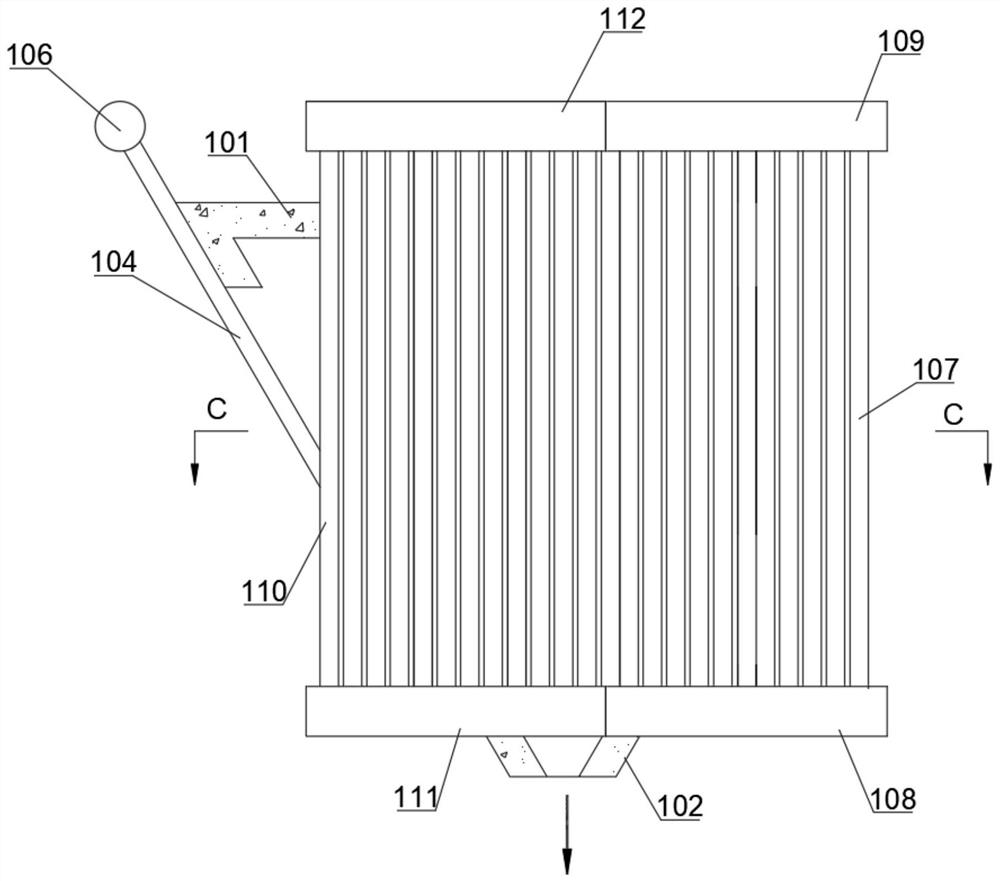

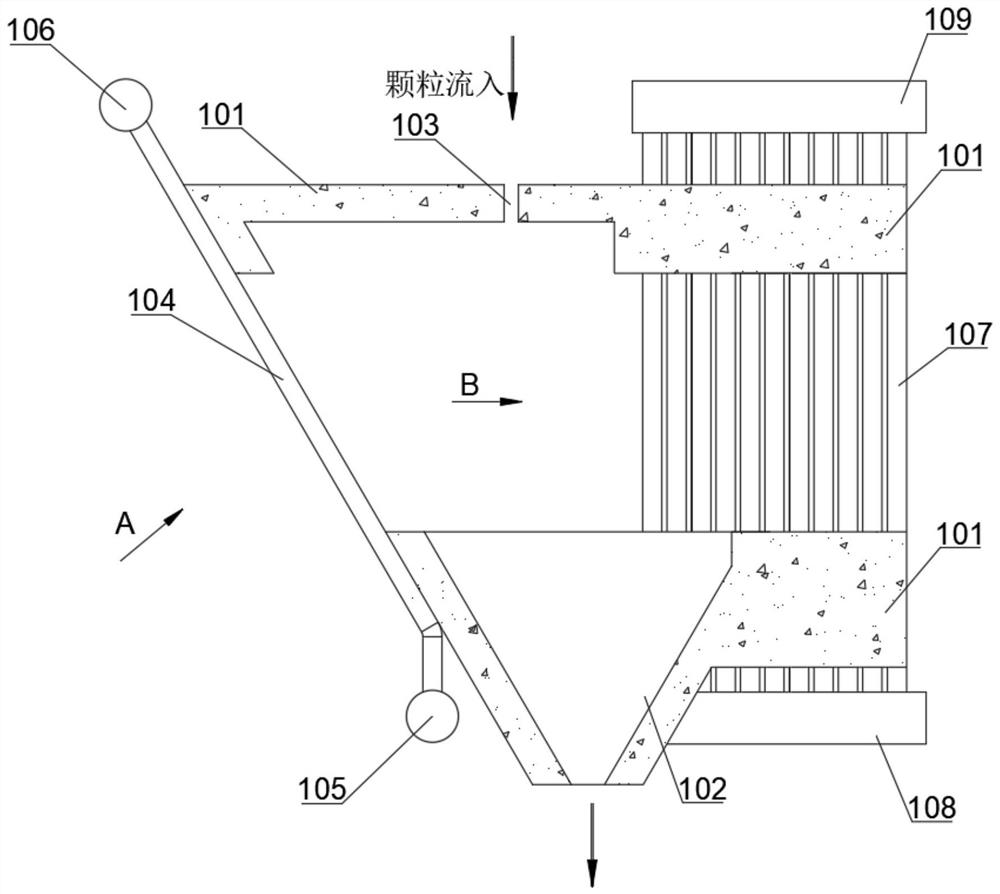

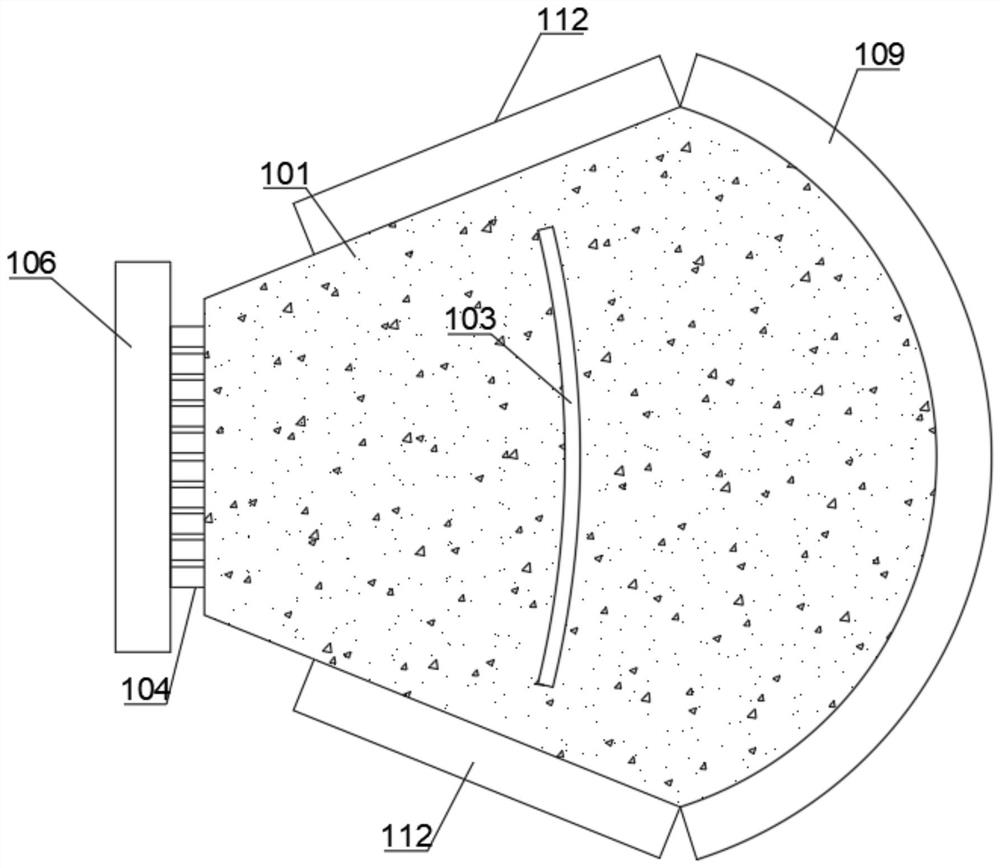

Image

Examples

Embodiment 2

[0053] see Figure 7 , this embodiment provides a heat absorption and storage system, including the cavity heat absorber 1 in the first embodiment above, which can realize the coupling of the particle heat absorber and the molten salt heat absorber.

[0054] Specifically, it can include particle heat absorption and storage systems and molten salt heat absorption and storage systems. Among them, the particle heat storage system can specifically include a particle heat tank 2, a particle / SCO 2 Heat exchanger 3, particle cold tank 4 and particle elevating system 5, the input end of particle heat tank 2 is connected with the output end of hot particle collecting hopper 102 of cavity heat absorber 1, and particle elevating system 5 can transfer cold particles The particles in the tank are lifted to the cold particle inlet 103 at the top of the cavity heat absorber 1, thereby realizing circulation.

[0055] The molten salt heat absorption and storage system may specifically includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com