A dedicated online anti-oxidation device for cathode rollers

A cathode roller and anti-oxidation technology, which is applied in the direction of mechanical equipment, engine components, electrolysis process, etc., can solve the problems of affecting the formation of electrolytic copper foil, unstable product quality, slow speed, etc., and achieve slow oxidation, significant effect, and no leakage less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

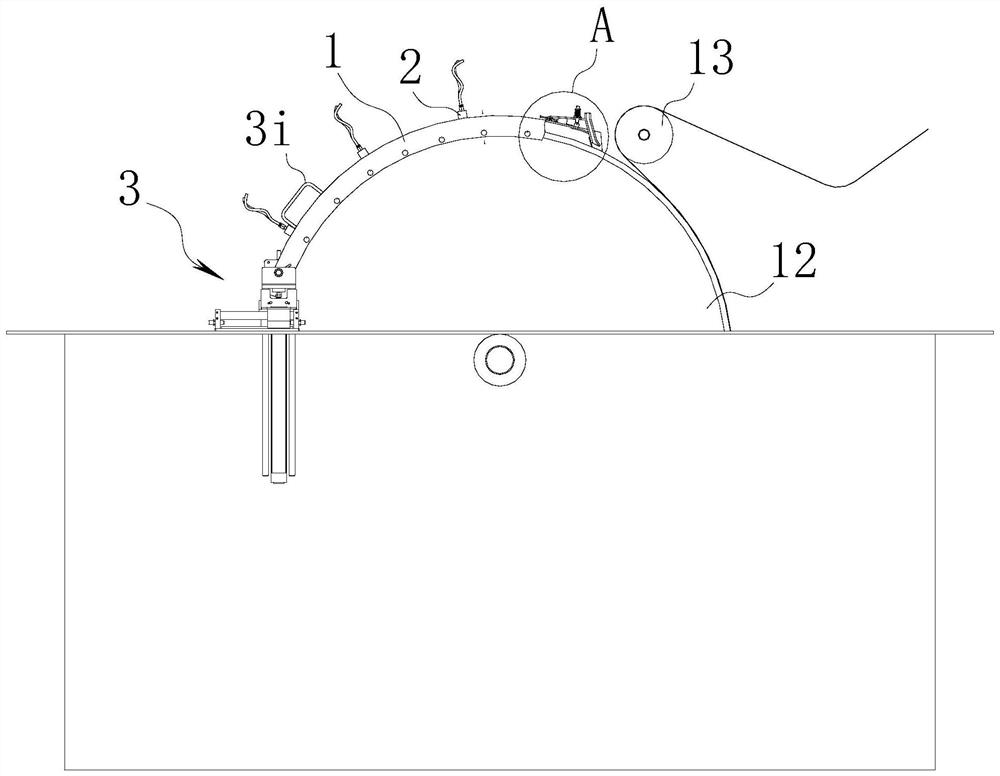

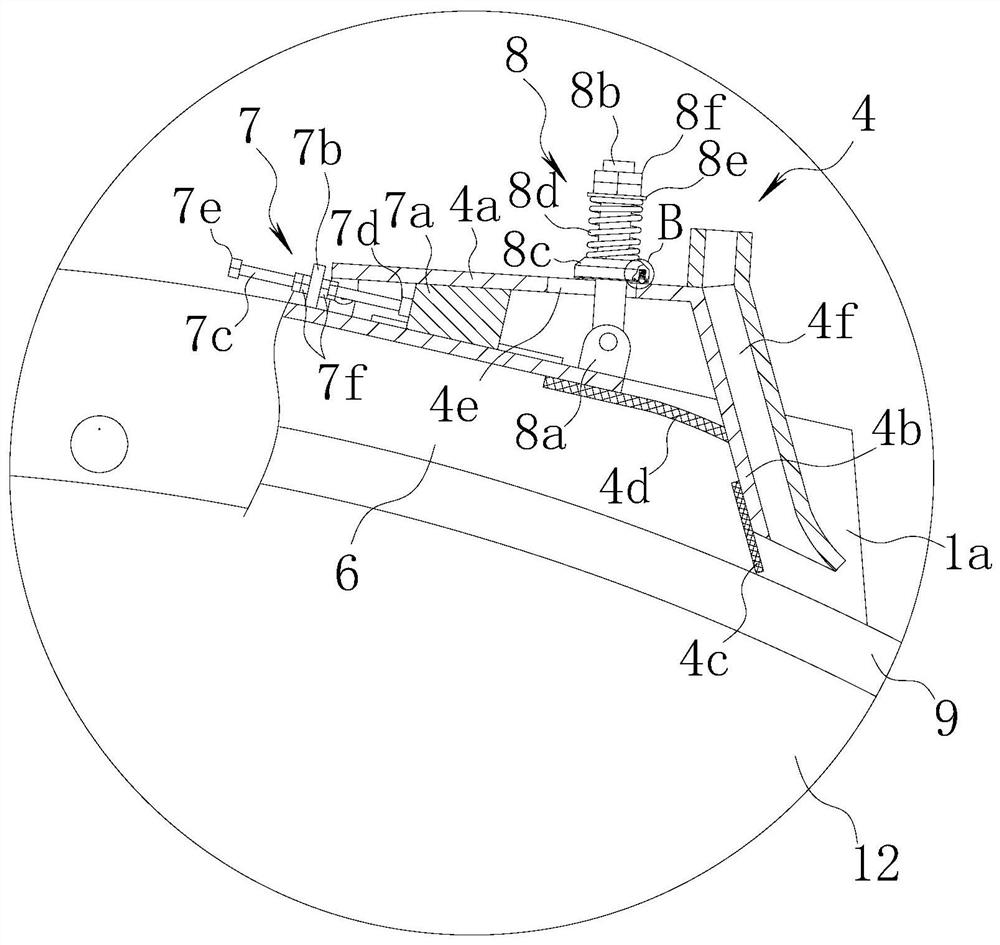

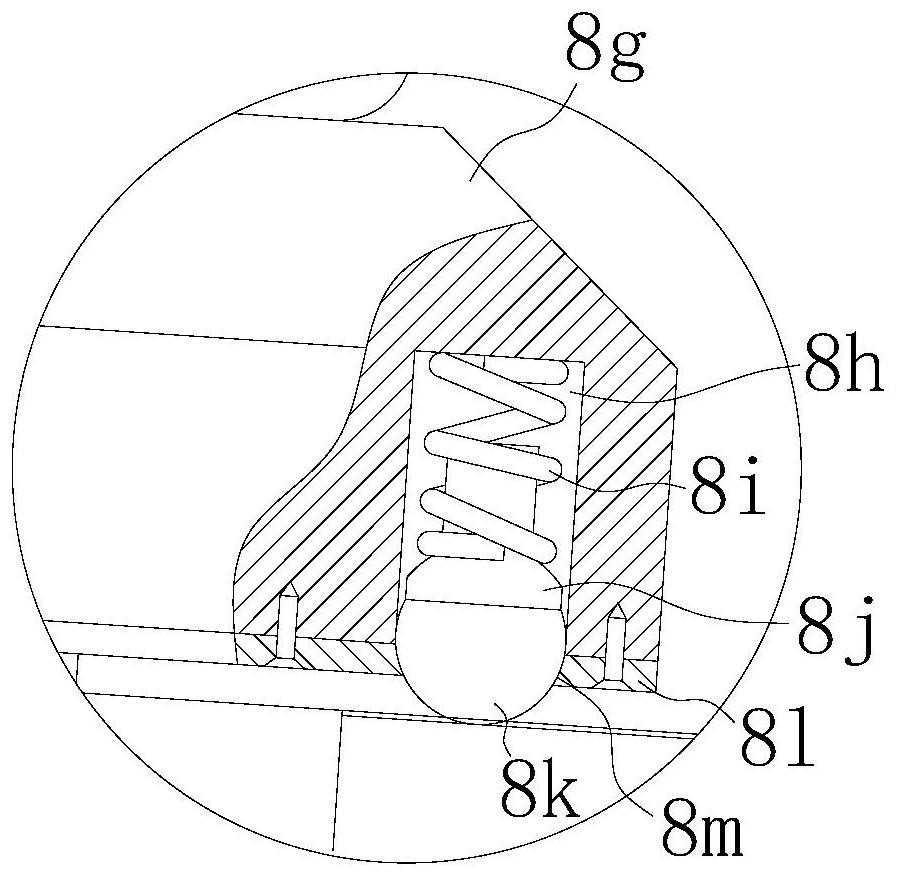

[0035] refer to Figure 1 to Figure 5As shown, a special on-line anti-oxidation device for cathode rolls of the present invention includes an isolation cover 1 that is arranged on the front side of the peeling roll along the rotation direction of the cathode roll, and several air inlet joints 2 are distributed on the upper surface of the isolation cover 1. The joint 2 is connected with an external compressed nitrogen source pipeline; a lifting and translation mechanism 3 is connected to the proximal end of the isolation cover 1 away from the peeling roller.

[0036] The upper and lower ends of the isolation cover 1 opposite to the cathode roll surface are respectively provided with adjustable isolation components 4, and the distance between the free end of the adjustable isolation component 4 and the cathode roll surface is 0.8-1.2 mm.

[0037] At the left and right ends of the isolation cover 1, there are dynamic sealing components 5 that match the end faces on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com