Hydraulic stroke transmitter

A hydraulic and stroke technology, applied in the field of hydraulic stroke transmitter, to achieve the effect of less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

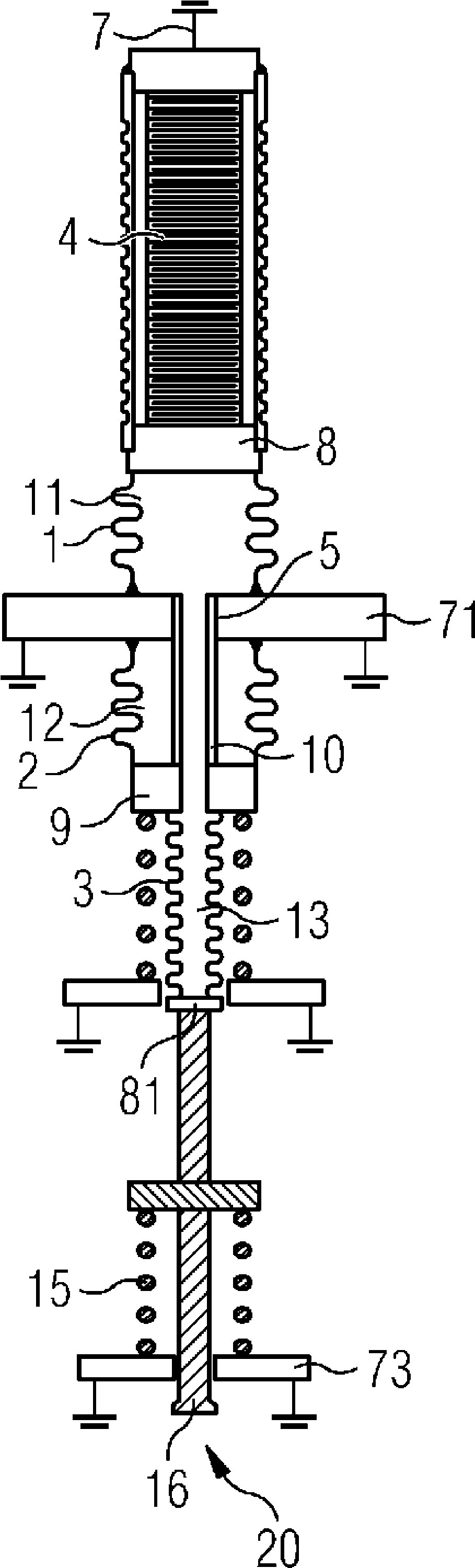

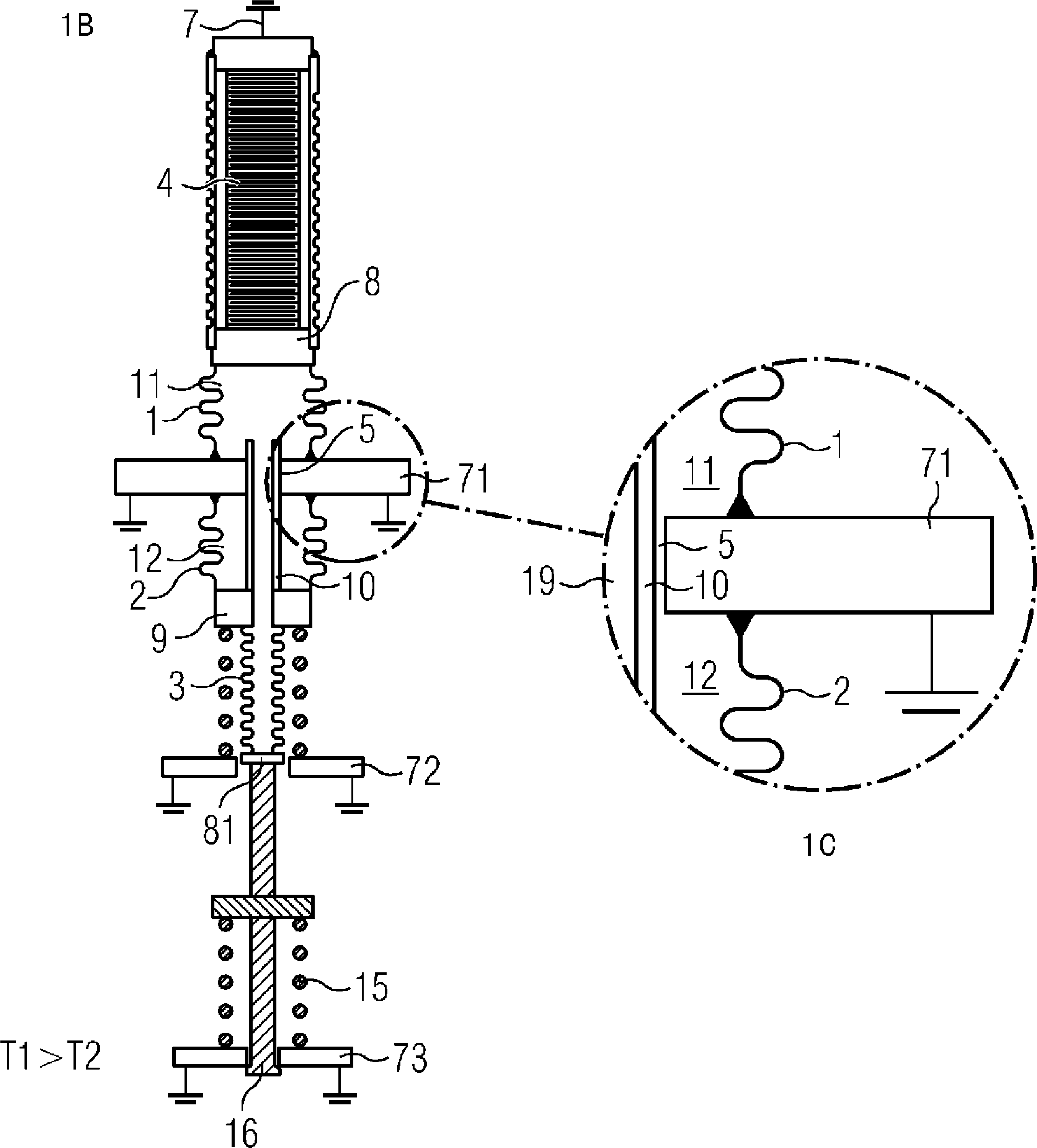

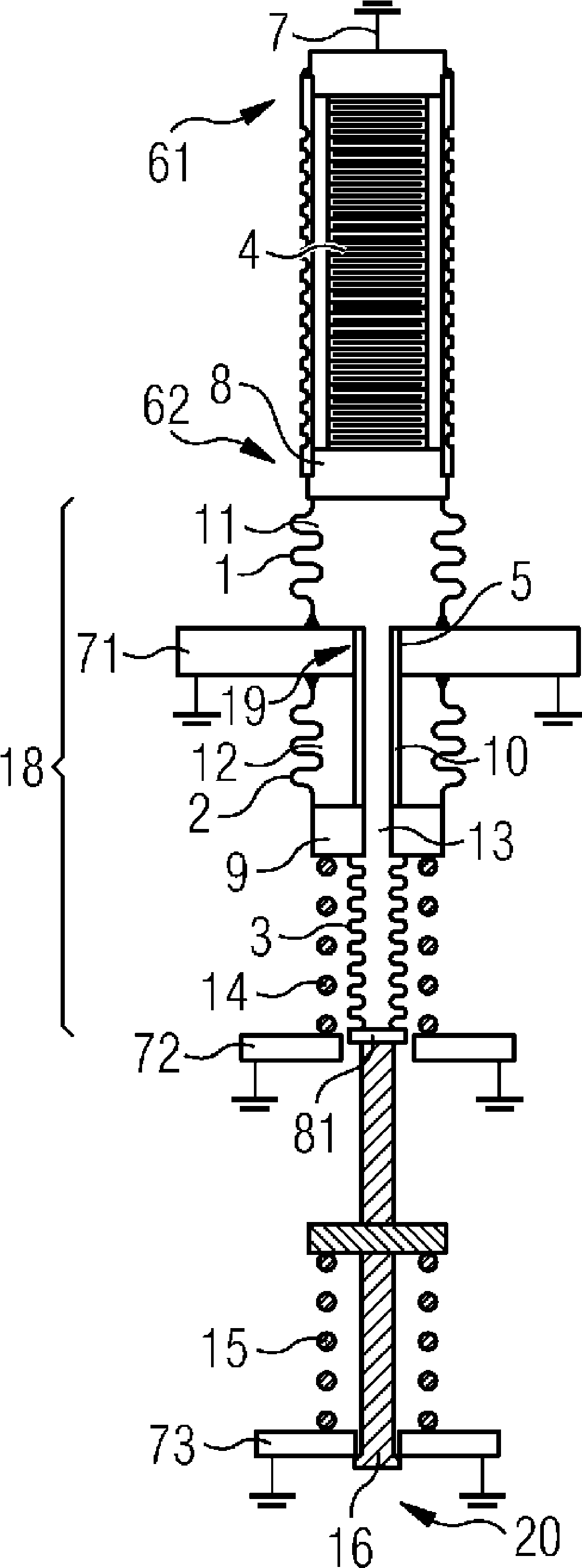

[0031] Figure 1A and 1B In principle the same structure is shown, where the Figure 1A There exists an operating temperature T1 in which the operating temperature T1 is greater than the corresponding Figure 1B The working temperature T2. The two figures have substantially the same structural components denoted by the same reference numerals. A solid-state actuator 4 is present here, which can be a piezoelectric actuator or a magnetostrictive actuator. The actuator is supported at the rear with its rear end 61 on the fixed bearing 7 . At the front end 62 of the solid-state actuator, the solid-state actuator has an end plate 8 which is preferably connected to the first metal bellows 1 by means of a weld. A first hydraulic volume 11 is shown here.

[0032] At its other end, the first metal bellows 1 is fixedly and gas-tightly connected to a fixed bearing 71, as seen in the axial direction of the solid-state actuator 4, preferably by means of a weld seam .

[0033] The fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com