Gas pipeline liquid metal sealing valve for high-temperature environment

A gas pipeline and liquid metal technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of purchase cost, increased use cost, unfavorable safety production and operation workers' life, health and safety, high production cost, etc., and achieve great technical effects And economic benefits, good promotion and use value, and long service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

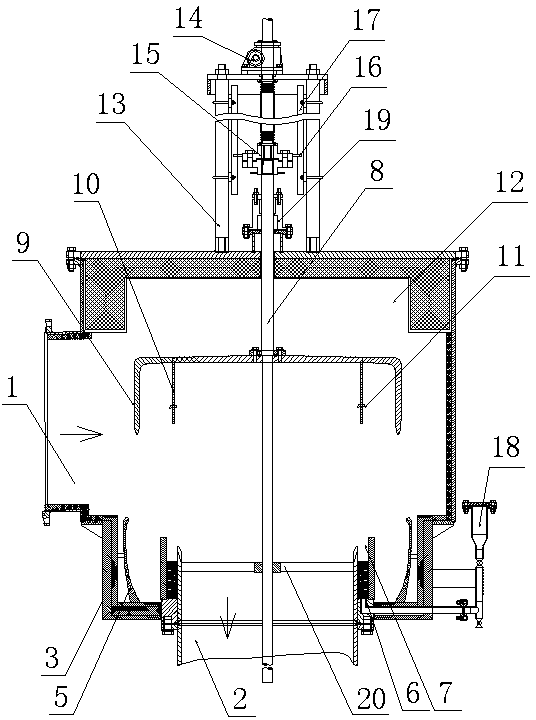

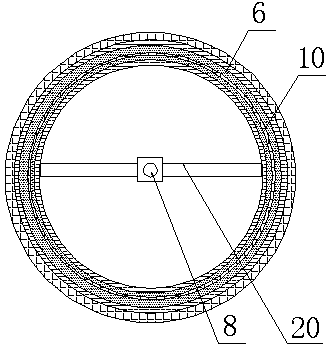

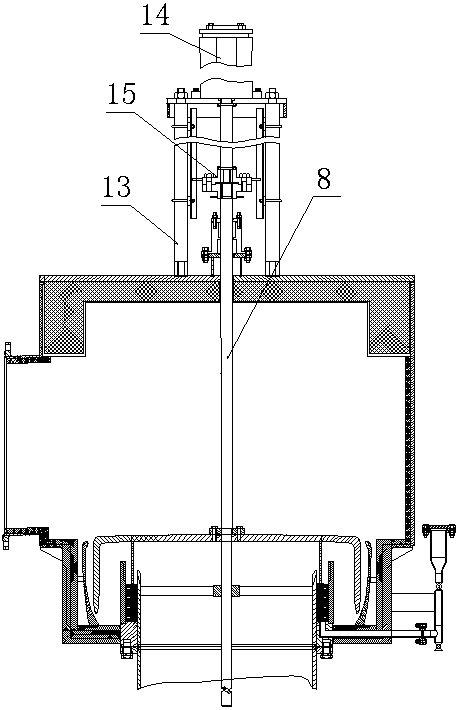

[0030] Such as figure 1 , 2 As shown, a gas pipeline liquid metal sealing valve for high temperature environment includes a valve body 3 provided with an air inlet 1 and an air outlet 2, and the bottom of the valve body 3 is provided with a conical sealing ring 5 and a seal filled with liquid metal 6 Groove 7, the valve body 3 is pierced with a valve stem 8, the upper part of the valve stem 8 is connected to the valve stem driving device, and the lower part of the valve stem 8 is connected to the isolation cover structure, and the isolation cover structure includes an outer shield 9 and the inner seal cover 10; the upper end of the conical sealing ring 5 is higher than the upper end of the sealing groove 7; the valve stem driving device includes a sleeve 13 arranged on the valve body 3, and the valve stem The output end of the driving device 14 is connected to the valve stem 8 through a coupling 15, the valve rod driving device 14 is an electric screw screw lifter, the valve ...

Embodiment 2

[0041] A gas pipeline liquid metal sealing valve for high-temperature environments, the difference from Embodiment 1 is that the air inlet end of the inner sealing cover 10 is set to be triangular, oval or circular, such as figure 1 As shown, a retaining ring 11 is provided on the lower peripheral side of the inner sealing cover 10 ; a groove 12 is provided on the inner side of the upper part of the valve body 3 , and the size of the groove 12 is slightly larger than that of the outer shield 9 .

Embodiment 3

[0043] A gas pipeline liquid metal sealing valve for high temperature environment, the difference from the first embodiment is that the number of the slide rails 17 is set to three or more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com