Flow controller and spent fuel aftertreatment system

A technology of flow controller and meter, which is applied in the direction of using electric device flow control, reactor fuel element, reducing greenhouse gas, etc., can solve the problems of radioactive material leakage, leakage, unreliable sealing method, etc., to achieve absolute sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

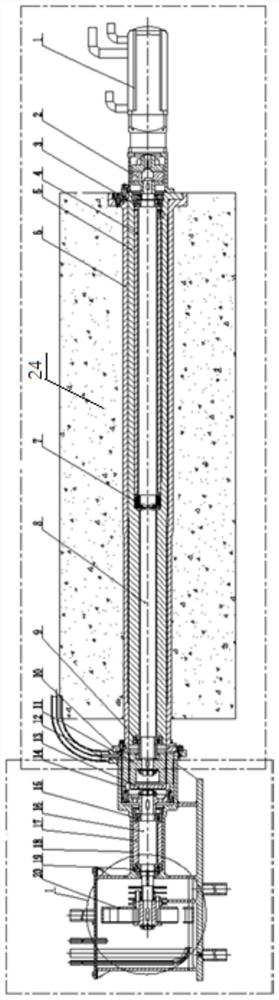

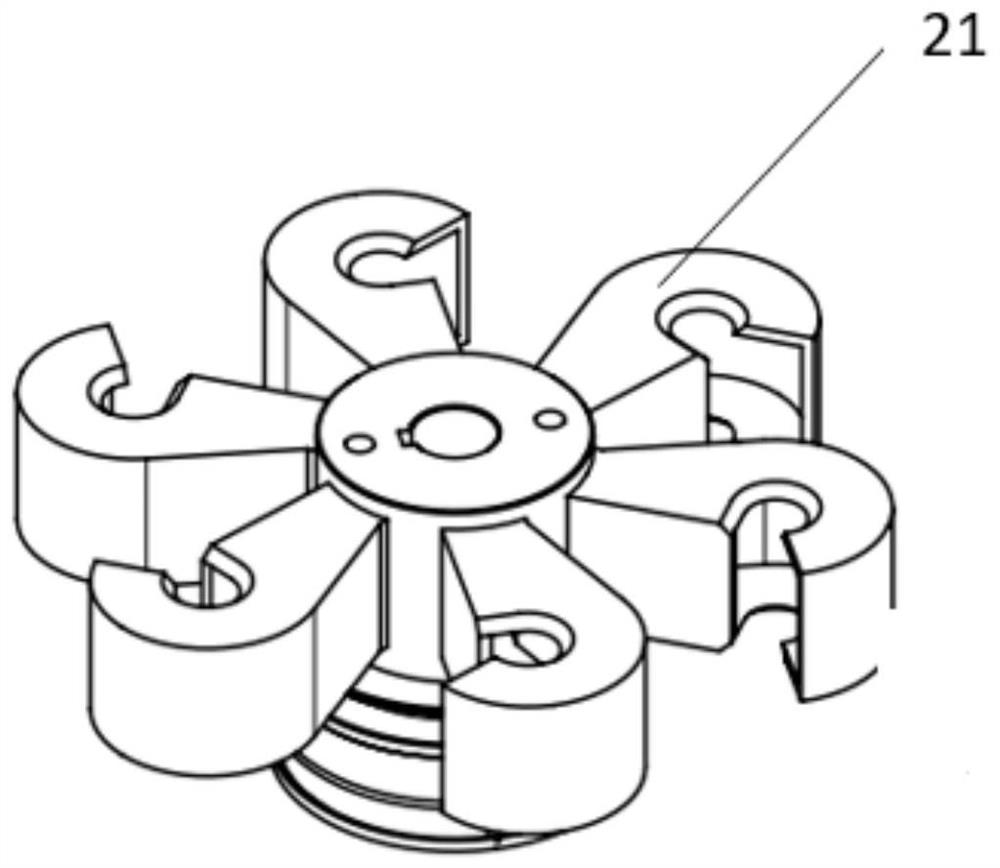

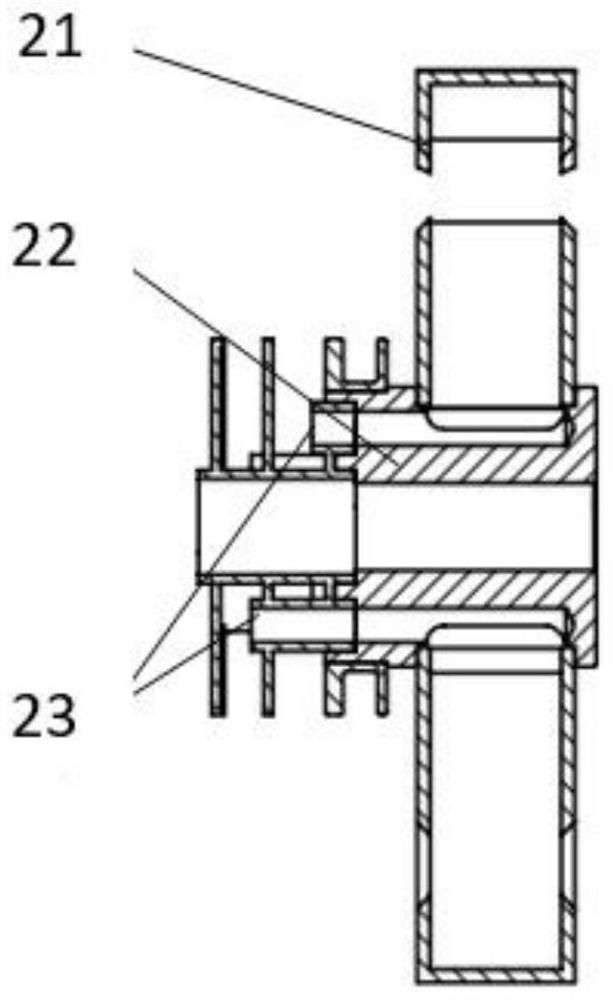

[0031] like figure 1 As shown, this embodiment discloses a flow controller, which includes a drive assembly 1, a transmission shaft assembly, an output shaft assembly, an isolation assembly and a doser 20. The drive assembly 1 is located outside the equipment room, and the transmission shaft assembly includes a transmission shaft 8 With the inner magnetic rotor 11, one end of the transmission shaft 8 is rotatably connected with the drive assembly 1, and the other end of the transmission shaft 8 extends into the equipment room through the wall 24 of the equipment room. Since the equipment room has the need to shield rays, the wall 24 The thickness of the transmission shaft 8 is set thicker, the setting length of the transmission shaft 8 also needs to be longer than the thickness of the wall 24, the transmission shaft 8 is cylindrical, the inner magnetic rotor 11 is installed at one end of the transmission shaft 8 located in the equipment room, and the output shaft assembly inclu...

Embodiment 2

[0055] The present invention also provides a spent fuel post-processing system, including an equipment room and the flow controller in Embodiment 1. The equipment room is used to isolate the drive assembly 1, and the flow controller is used to sample the feed liquid and measure the flow.

[0056] The drive assembly 1 is located outside the equipment room, and is connected to the output shaft 16 inside the equipment room through the transmission shaft 8, which is used to drive the transmission shaft 8 and the output shaft 16 to rotate, and then drives the quantizer 20 to rotate and sample, and complete the measurement of the material and liquid. Sampling and flow measurement.

[0057] The spent fuel post-processing system in this embodiment has the function of continuously and uniformly measuring and controlling the flow of the feed liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com