Cable-stayed incremental launching construction method of large-span steel beam

A technology of jacking construction and large span, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., to achieve the effect of simple structure, saving construction cost and reducing deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] One kind of large span steel beam oblique pushing construction method, comprising the steps of:

[0044] Step 1, set the auxiliary support member, set the assembly platform, install the top push equipment;

[0045] Step 2, install the guide, pre-collating the beam;

[0046] Step 3, stepped in the top push combined mounted beam;

[0047] Step 4, install the cable, top push the beam body with a traverse system;

[0048] Step 5, the beam body beam, conversion system;

[0049] Step 6, dismantle cable-stayed system, push-stayed construction is completed.

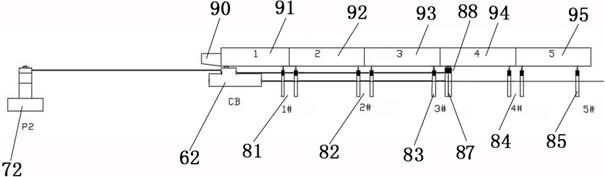

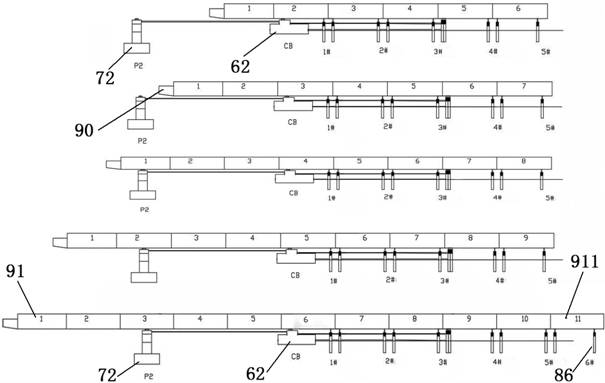

[0050] Step 1 In the auxiliary support member 61 includes a front abutment, pier first column 71, the second pillar 72 and a rear abutment piers 62. Platform assembly 62 disposed at the rear end of the rear end of the abutment, the platform assembly comprising a plurality of groups temporary pier, pier chute 87 and guide rails 88 group.

[0051] Group pier chute 87 disposed between two sets of adjacent groups temporary pier, a...

Embodiment 2

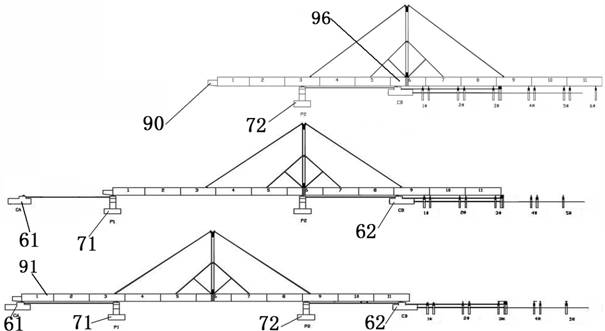

[0058] This Example compared to Example 1, except that a: the step 4 of the oblique installation system comprises a pylon, tension bench 2, 3 slab anchor stent, strand 4 and 5 strut.

[0059] Beam anchoring brackets tower 1 through 3 is fixed perpendicular to the intermediate section steel beams. 4 strand tensioned symmetrically on both sides of a tower, one end of the base 2 taut strand 4 to the top tower 1, another steel beam 4 across the end of the tensioning strand by the tension of beam sets. Disposed symmetrically on both side of the strut tower 5 1 end of the support tower, and the other end sides of the intermediate section steel beams supporting steel beams.

[0060] 1 comprises a steel tower 11, the steel pipe 12 connected to the flange, the hoop 13 and stiffening bracket 14. Hoop 13 is provided on the outer periphery of the steel pipe 12 connected to the flange 11 of the steel tubes, strut tower 5 is supported by a hoop 13. Hoop 13 looped inner tube 11 is provided at th...

Embodiment 3

[0064] The present embodiment as compared with Example 2, except that a: the platform assembly comprising a set of six temporary pier, a pier group chute 87 and slide 88 in three rows. Six temporary pier group comprising a first set of temporary pier 81, a second temporary pier group 82, the third temporary pier group 83, the fourth group of temporary pier 84, the fifth and the sixth group 85 temporary pier temporary pier 86 group. Group pier chute 87 is provided between the third and the fourth group 83 temporary pier temporary pier 84 group. And the third chute 88 by temporary pier beam group 83, a second temporary pier group 82, a first set of temporary pier 81, 62 connected to the rear end of the abutment. Temporary pier top of the third group 83, the rear end of the table top bridge 62, the top of the second column piers 72, 71 is mounted on top of the first column pier walker pushing device. Beam plate girder beam spell three, six groups were provided temporary pier three lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com